Curved surface printer

A technology of printers and curved surfaces, which is applied in typewriters, printing, etc., can solve problems such as printing on substrates that cannot be printed and short service life of printers, and achieve the effects of avoiding weak connections, ensuring stable connections, and ensuring overall effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

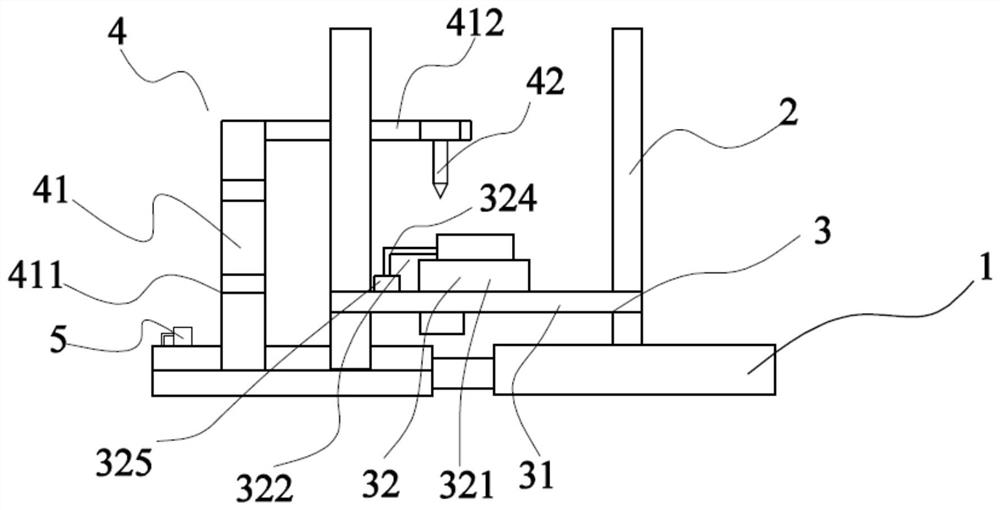

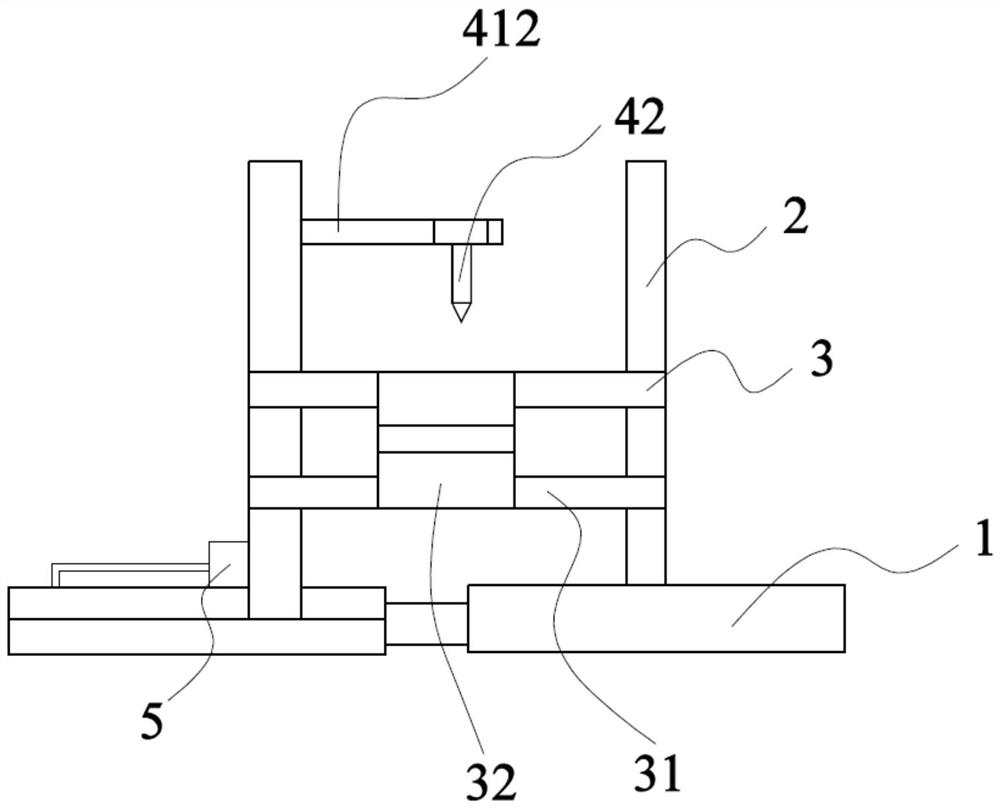

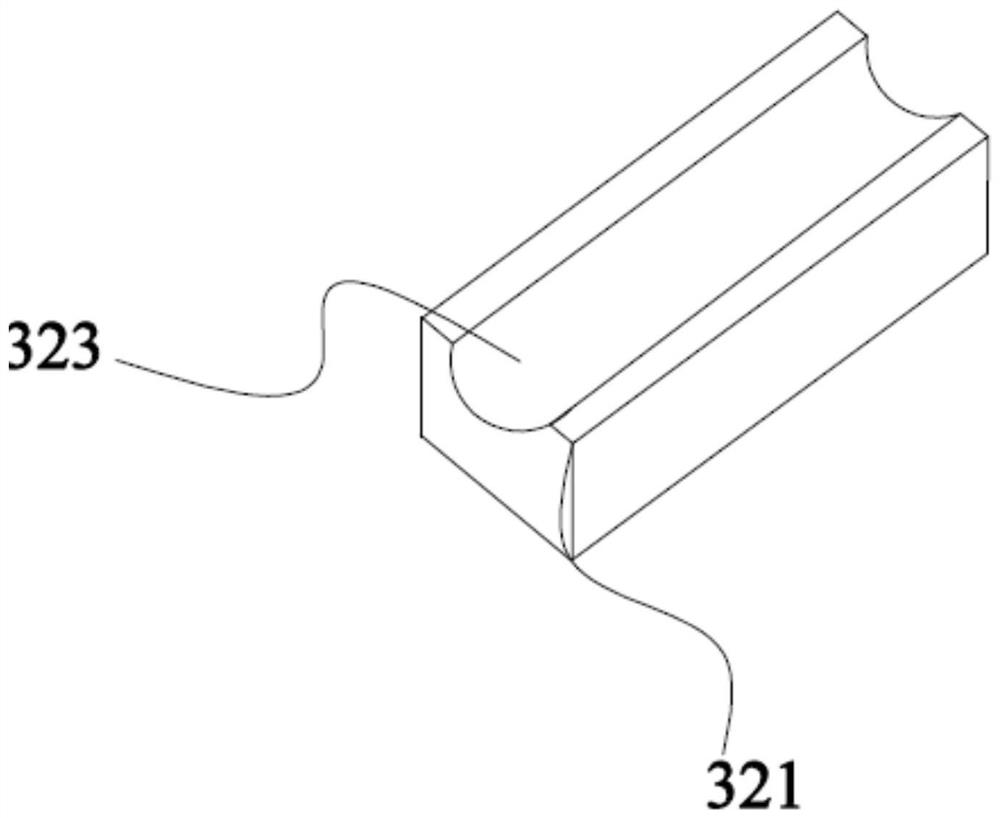

[0027] Such as Figure 1 to Figure 5 It is an embodiment of a curved surface printer of the present invention, including a base 1, two fixing plates 2, a rotatable fixing frame 3 for installing and fixing a base material to be printed, and a printer main body 4 for printing on a base material to be printed, The two fixed plates 2 are fixedly installed on the base 1 , the rotatable fixed frame 3 is slidably installed between the two fixed plates 2 and rotatable, and the printer main body 4 is slidably installed on the base 1 .

[0028]Wherein, the printer main body 4 includes a liftable connecting rod 41 and a printing head 42 , and the connecting rod 41 is fixedly connected with the printing head 42 . The fixed connection between the connecting rod and the printing head ensures the reliability of the connection of the printing head, avoids the situation that the connection is not strong, and ensures the stable connection of the printing head. Through the liftable setting of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com