An assembled steel structure node component and its use method

A steel structure, prefabricated technology, applied in the direction of building structure, construction, etc., can solve the problems of unstable connection, poor safety performance, wear at the connection, etc., to maintain synchronization and stability, strengthen connection, Wear reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

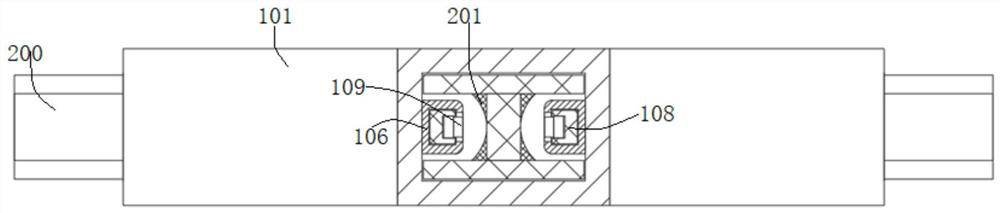

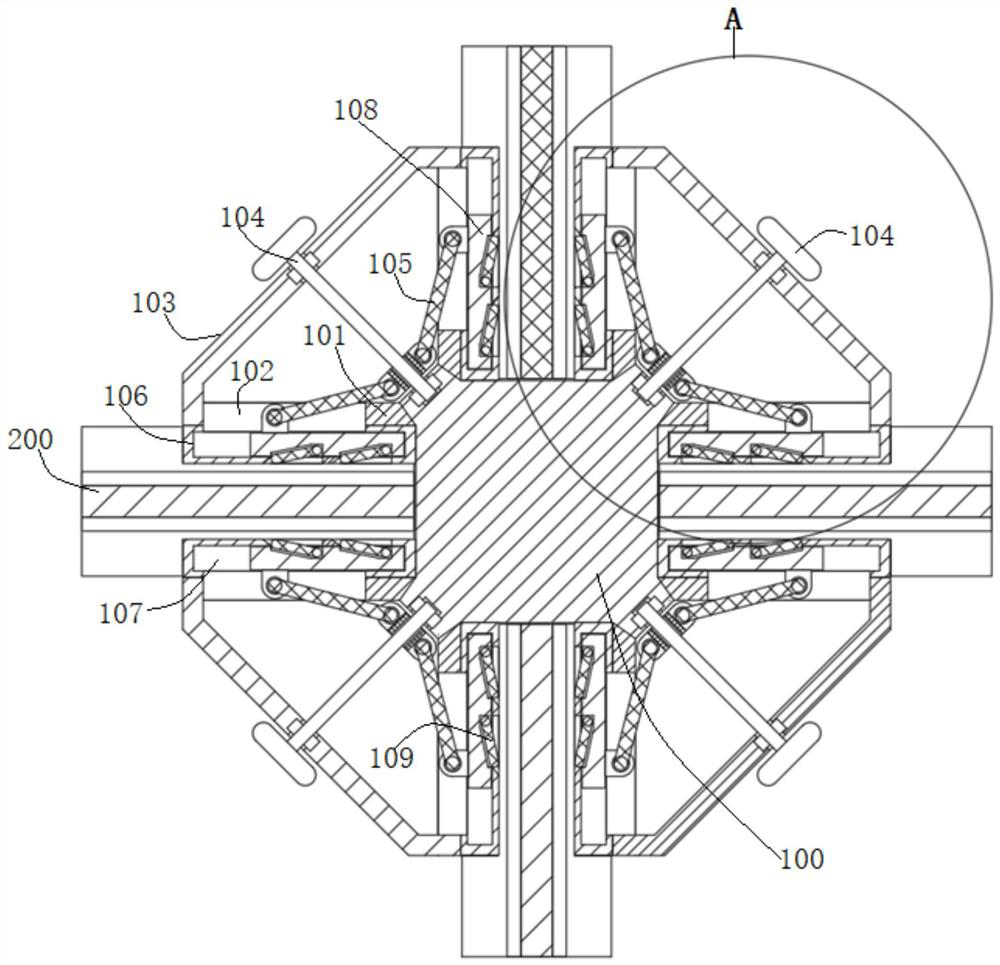

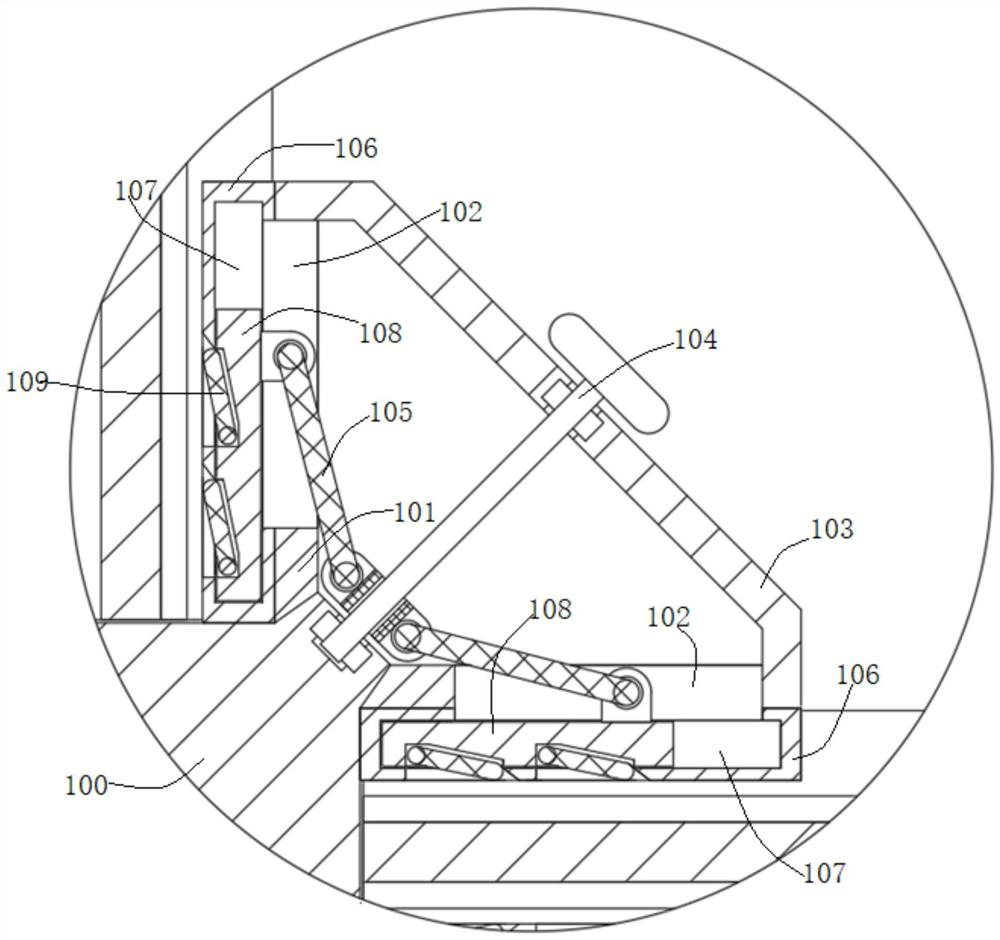

[0036] like Figure 1-Figure 4 As shown, an assembled steel structure node member in this embodiment includes a central plate 100, and the surrounding sides of the central plate 100 are respectively provided with installation grooves 101, and the installation grooves 101 are equipped with I-shaped steel 200 for cooperating with the installation. The sleeve 106, the I-shaped steel 200 is inserted in the sleeve 106 during actual use; the two sides of the installation groove plate 101 are provided with a section of slide channel channel 102 along the length direction, and the two sides of the sleeve 106 A section of moving chute 107 communicating with the chute channel 102 is correspondingly opened on the outer wall along the length direction, and a sliding bar 108 is arranged in the moving chute 107, and the sliding bar 108 is connected with the power assembly and driven by it to move along the moving chute. 107 slides, and the inner walls at both ends of the moving chute 107 ca...

Embodiment 2

[0040] An assembled steel structure node component in this embodiment is basically the same as in Embodiment 1. Furthermore, the power assembly in this embodiment includes a screw 104 and a rotating rod 105. The screw 104 is located on the side of the installation groove plate 101, and the screw 104 The tail end and the center plate 100 can be connected through bearing rotation and fit, and the screw rod 104 is equipped with a sliding nut, one end of the rotating rod 105 is hinged with the side of the sliding nut, and the other end of the rotating rod 105 passes through the slide channel channel 102 and The end of the sliding rod 108 is hinged, and the sliding nut can be driven to translate by the rotation of the screw rod 104 , and finally the sliding rod 108 is driven to translate and slide in the moving chute 107 .

[0041] Furthermore, in the present embodiment, a group of screw rods 104 are shared between the installation channel plates 101 on the adjacent two sides around...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com