Sensing optical fiber unit structure for pipeline risk monitoring and early warning and construction method

A technology for sensing optical fiber and risk monitoring, which is applied in the use of optical devices to transmit sensing components, fiber mechanical structures, optical components, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

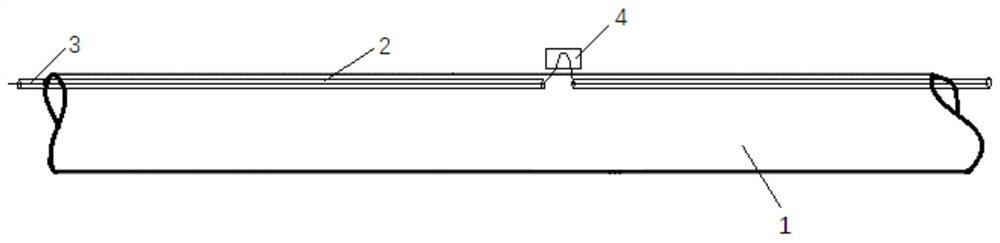

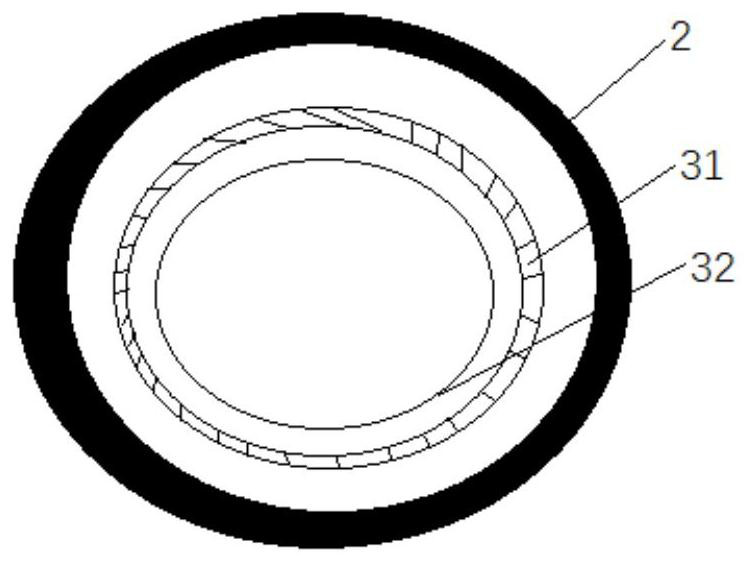

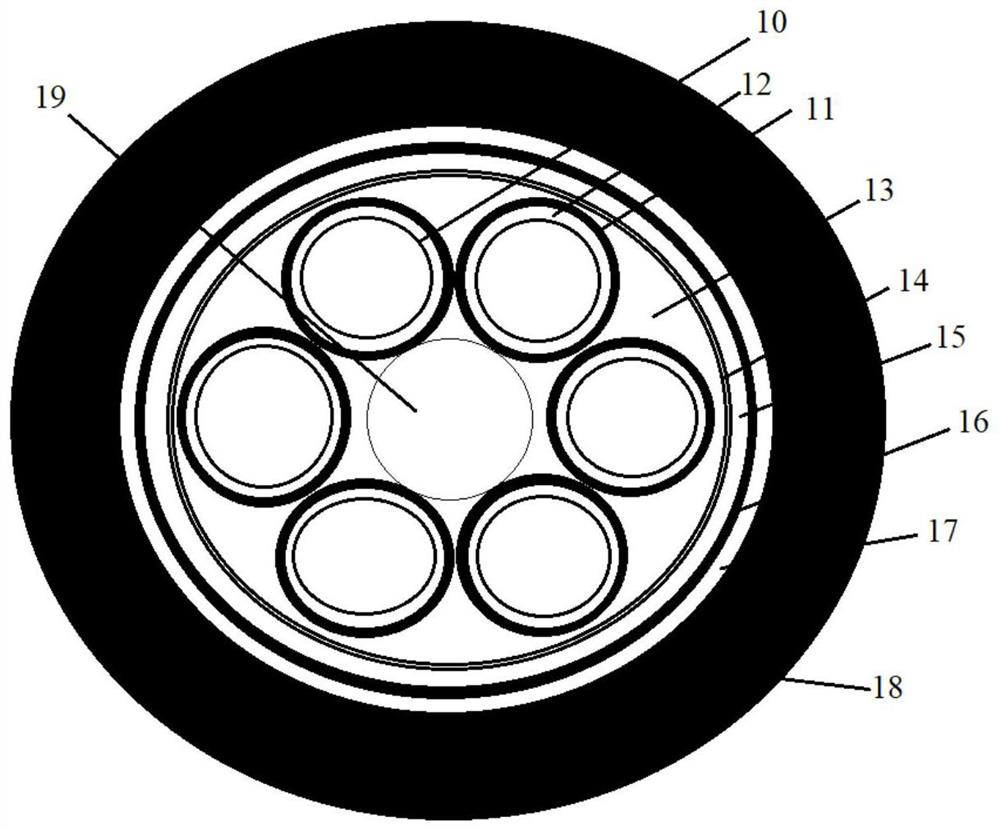

[0031] like Figure 1-2As shown, a sensing fiber unit structure for pipeline risk monitoring and early warning in this embodiment is composed of a microtube 2 protecting the sensing fiber unit 3 and a sensing fiber unit 3 . The micropipes 2 are formed by a plurality of micropipes 2 sealed from end to end, and can be quickly and synchronously laid on the outer wall of the medium conveying pipeline 1 within a limited window period during the construction of the medium conveying pipeline 1. The micropipes can be laid according to It is necessary to cut off and connect at any time and place to avoid various contradictions and mutual interference between the construction of the medium conveying pipeline 1 and the construction of the microtube 2, and save the construction period; and to avoid or reduce the connection of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com