Pipetting device and method

A pipetting device and liquid pipetting technology, applied in chemical instruments and methods, measuring tubes/pipettes, laboratory utensils, etc., can solve problems such as reducing the sensitivity of pipette tips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

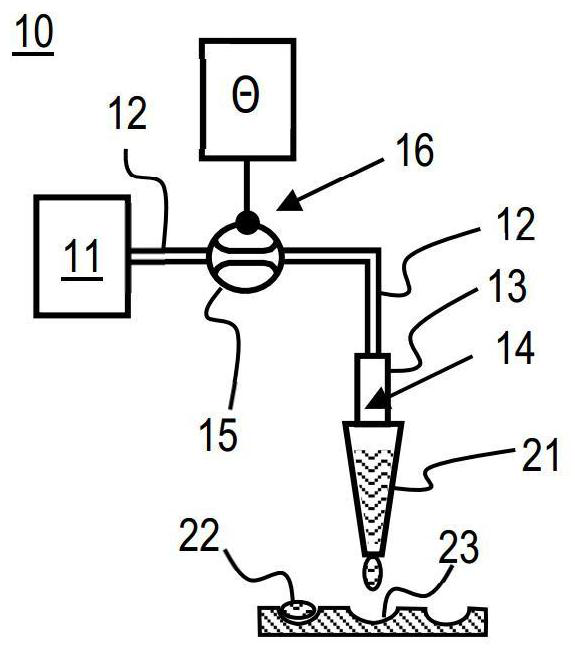

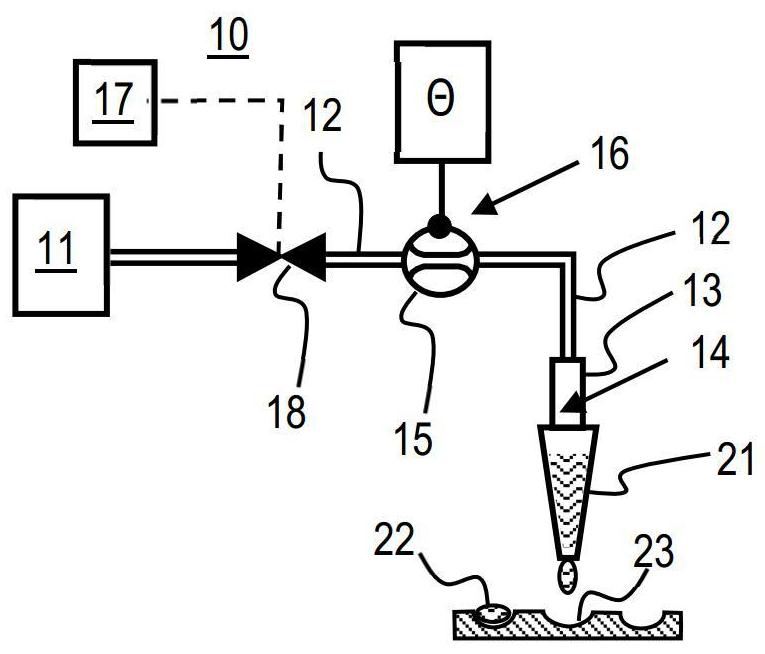

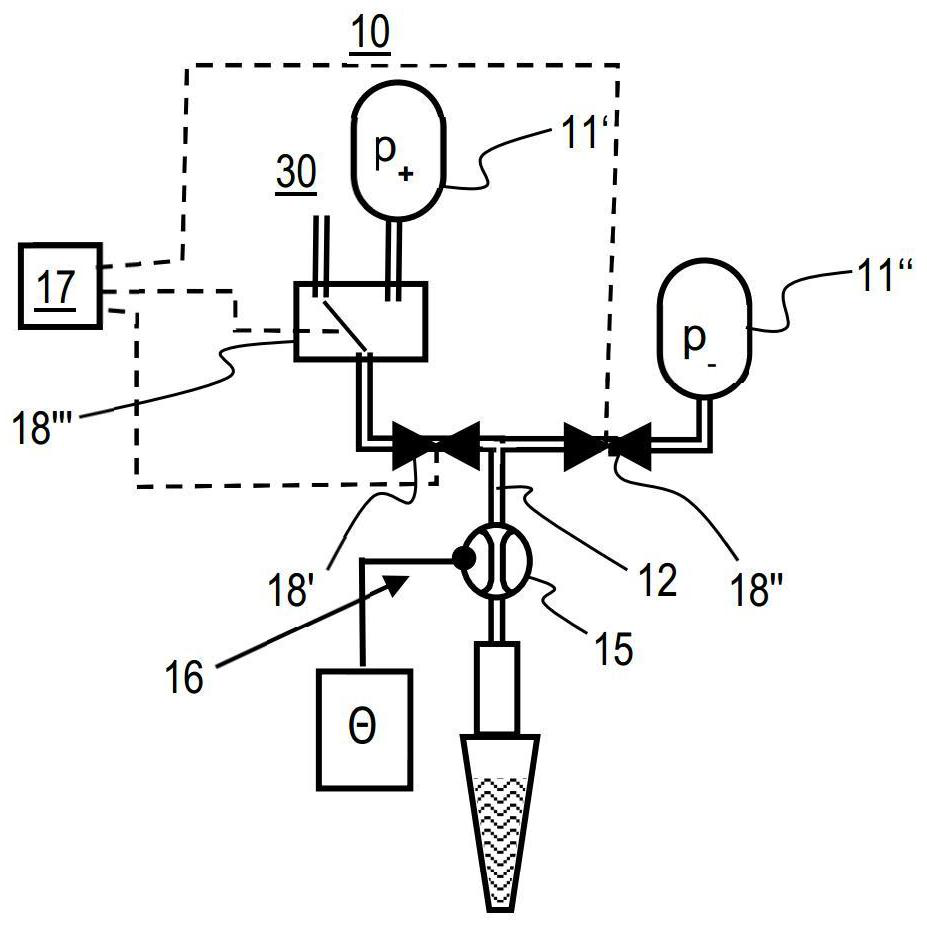

[0070] Fig. 1 shows schematically and simplified a pipetting device 10 according to the invention. In order to illustrate its function, this view shows, in addition to the pipetting device itself, other further elements in a specific pipetting situation. The pipetting device shown has a pipette 21 attached to the connection opening 14 of the pipette connector 13 . The pipette shown in this view contains a liquid which is now under the pressure of the gaseous working volume which enters the pipette 21 through the connection opening 14 . A drop of liquid is pushed out of the opening of the pipette opposite the opening of the pipette connected to the connection opening of the pipetting device. The previously generated liquid volume 22 is located in one of the wells 23 of the well plate arranged below the pipette tip.

[0071] The gaseous working medium is pressurized by the pressure source 11 . A gas flow connection through which a gaseous working medium can flow from the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com