Transmission type automatic board feeding equipment of drying machine

An automatic board feeding and transmission technology, applied in drying, lighting and heating equipment, wood drying and other directions, can solve the problems of wrong board placement, inability to dry the board, and inability to completely dry the board, so as to facilitate the adjustment of the board, Make sure to move into the dryer for easy compaction to limit the effect of the plank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

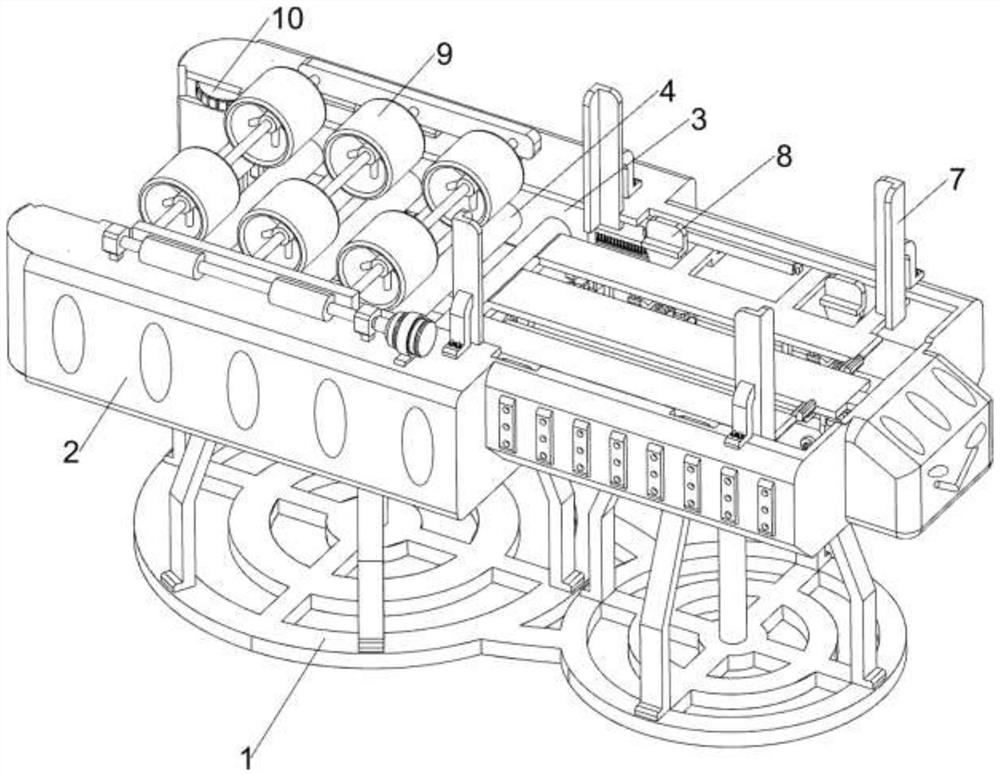

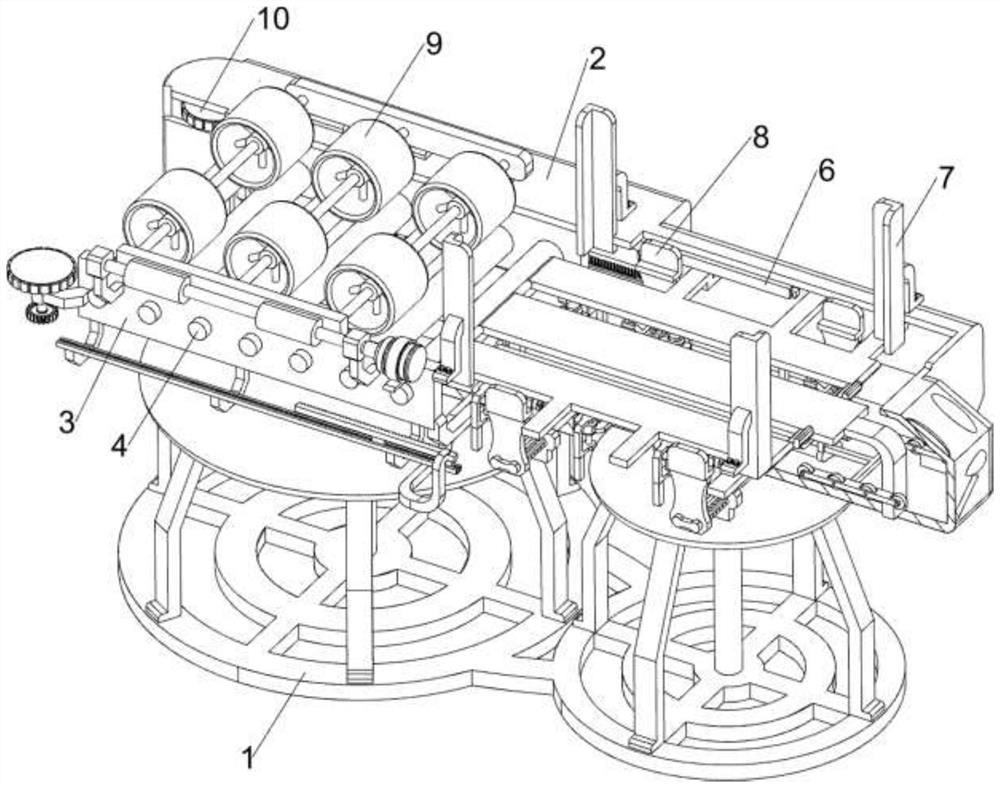

[0029] like Figure 1 ~ Figure 4 As shown, this embodiment discloses a drying machine transmission type automatic plate feeding equipment, including a support frame 1, a box body 2, a fixed plate 3, a transmission shaft 4, a transmission mechanism 5 and a drive mechanism 6, and the upper part of the support frame 1 is left The box body 2 is connected to the side, and the left side of the box body 2 is symmetrically connected with the fixed plate 3 front and rear. , A drive mechanism 6 is provided between the lower parts of the fixed plate 3 .

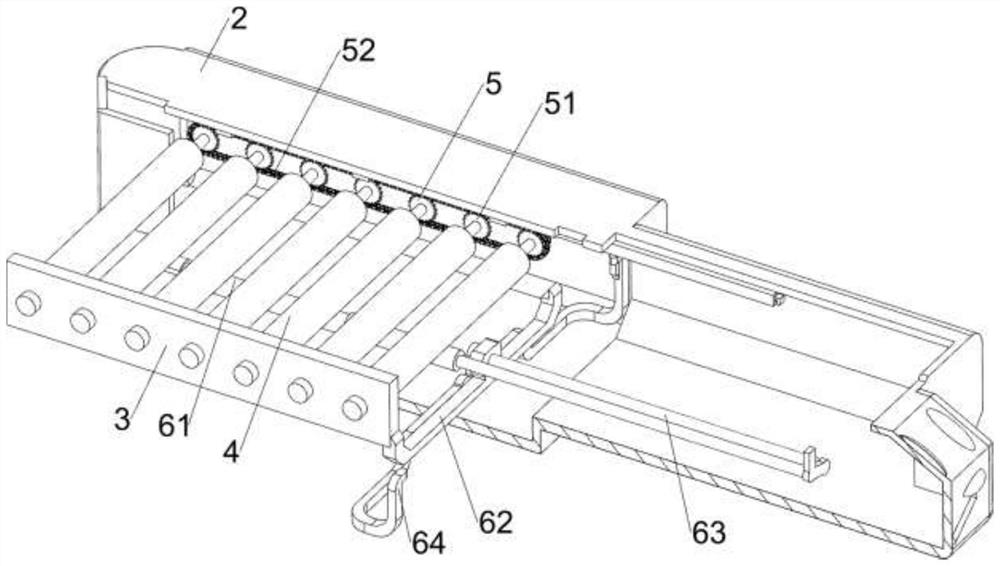

[0030] The transmission mechanism 5 includes a sprocket 51, a chain 52 and a first one-way gear 53. The rear side of the transmission shaft 4 transmission shaft is connected with a sprocket 51, and a chain 52 is connected between the sprockets 51. The rightmost transmission shaft 4 The rear end of the transmission shaft is connected with a first one-way gear 53 .

[0031] The driving mechanism 6 includes an electric push rod 61, a fir...

Embodiment 2

[0034] like figure 1 , figure 2 , Figure 5 ~ Figure 10 As shown, in some embodiments, it also includes a feeding assembly 7, and the feeding assembly 7 includes a positioning plate 71, a top material plate 72, a mounting plate 73, a slide rail 74, a pushing block 75 and a connecting rod 76, and the box Two positioning plates 71 are symmetrically connected front and back on the right side of the upper part of the body 2, a top material plate 72 is connected symmetrically front and rear on the upper right side of the inner part of the box body 2, and a mounting plate 73 is connected in the middle of the lower right side of the inner part of the box body 2, and the upper side of the connecting block 68 A pusher block 75 is connected, and the mounting plate 73 bottom is connected with a slide rail 74, and the pusher block 75 is slidably connected with the slide rail 74, and a connecting rod 76 is connected between the top plate 72 and the left side of the mounting plate 73.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com