A method for analyzing the segregation distribution of impurity elements in quartz lattice

An analytical method and technology of impurity elements, applied in the direction of removing certain components, weighing, molecular entity identification, instruments, etc., can solve the problem of inability to accurately measure the lattice impurity elements in natural quartz, and make up for the inability to accurately measure, Make up for technical defects and small deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0032] The embodiment of the present invention provides a method for analyzing the segregation distribution of impurity elements in a quartz lattice, comprising the following steps:

[0033] S1. Obtain the mass, volume and initial impurity content of the quartz to be analyzed;

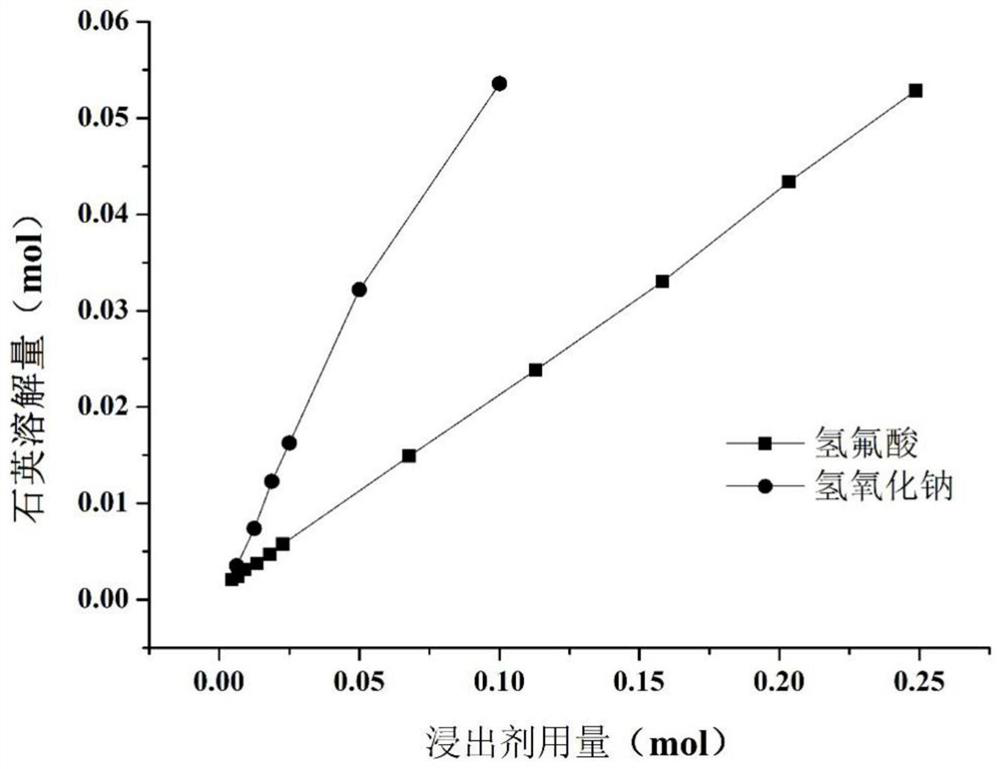

[0034] S2. Use denuding agents of different concentrations to ablate the quartz surface, and obtain the quality of each ablated quartz and the impurity content in the quartz after each ablation;

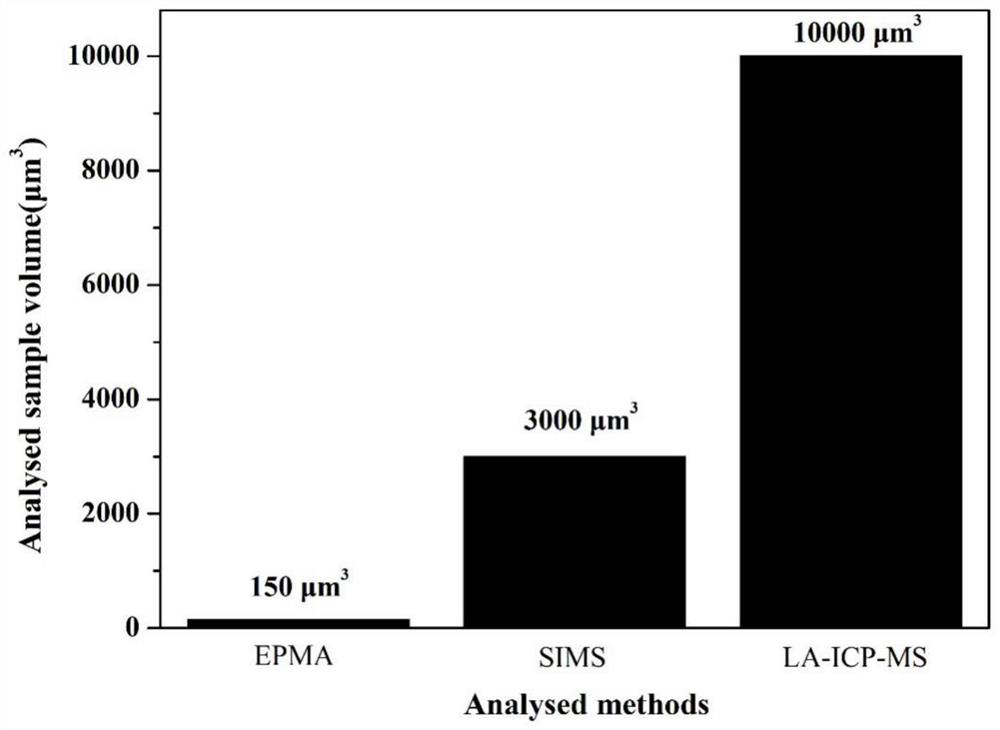

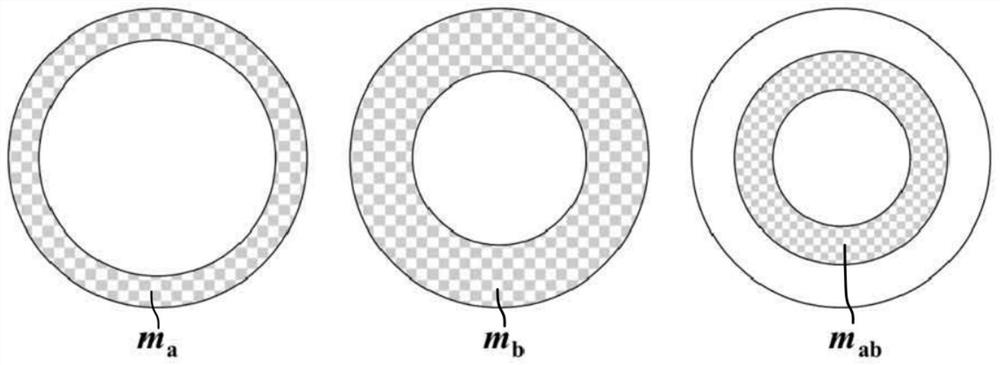

[0035] S3, according to the parameters obtained in the S1 step and the S2 step, establish a mathematical model based on the average content of i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com