An adsorption tower of a low dew point compressed air purification device

A technology of compressed air and purification equipment, which is applied in the field of adsorption towers, can solve the problems of wasting manpower and working time, and cannot process waste gas intelligently, and achieve the effects of saving time, reducing work burden, and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

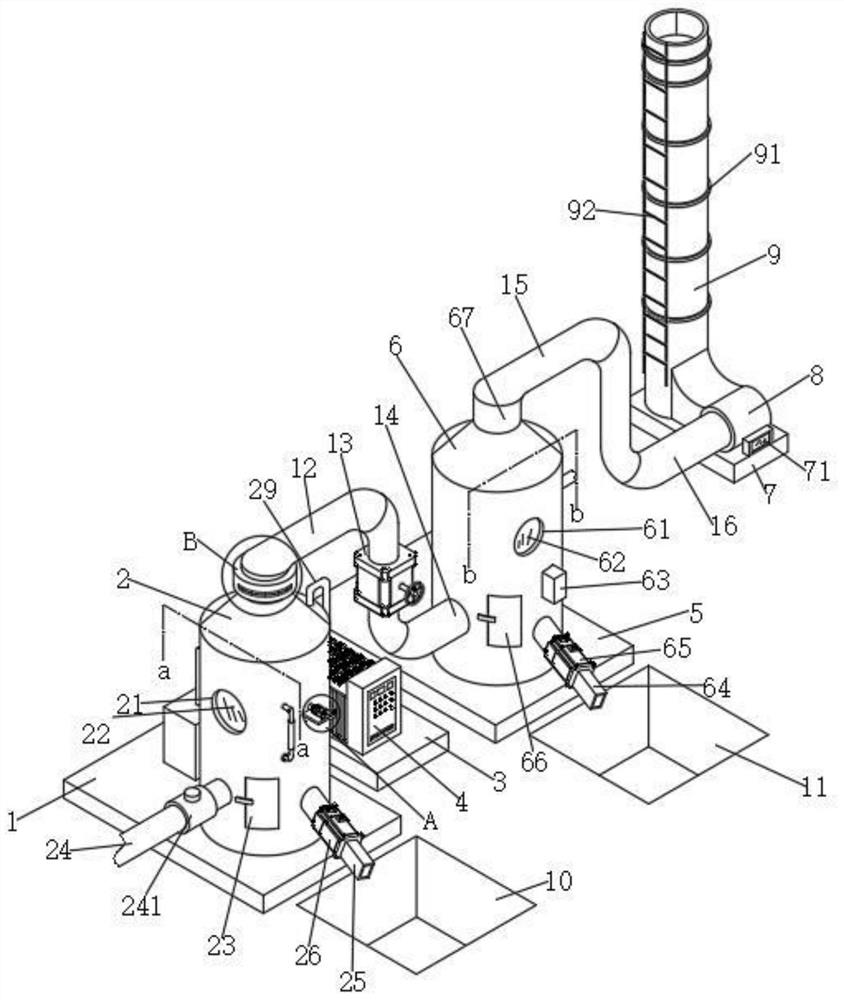

[0050] An adsorption tower of a low dew point compressed air purification device according to an embodiment of the present invention includes: a first base 1 , a second base 3 , a third base 5 , a fourth base 7 and a PLC controller 631 .

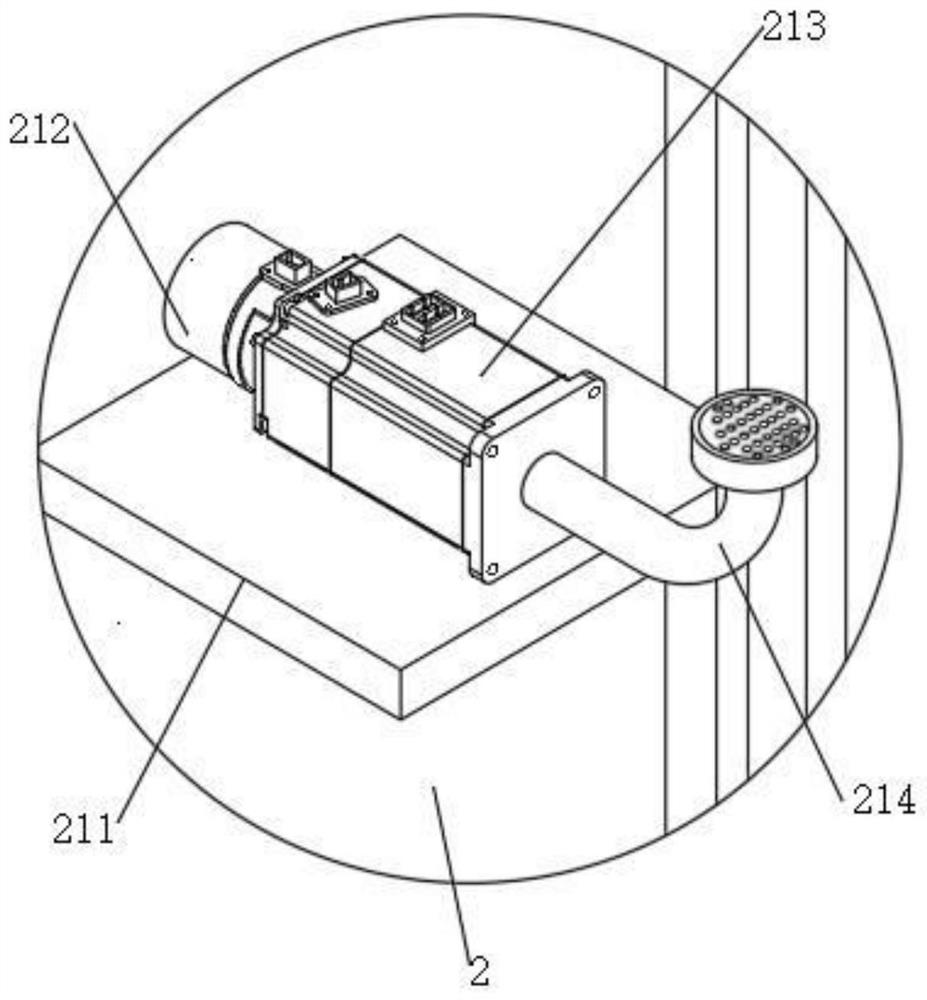

[0051] Wherein, the air compression tower 2 and the compressor 17 are fixedly installed on the first base 1, and one side of the air compression tower 2 communicates with the compressor 17 through the fifth L-shaped guide pipe 171, and the fifth L-shaped guide pipe 171 vertically runs through On one side of the air compression tower 2, and one end of the fifth L-shaped guide pipe 171 located in the air compression tower 2 is connected with an air injection disc 172, and the bottom of the air injection disc 172 is communicated with an air injection head 173, and the other side of the air compression tower 2 The first waste material outlet 25, the vent hole 212 and the U-shaped safety pipe 215 are connected respectively, the first waste materia...

Embodiment 2

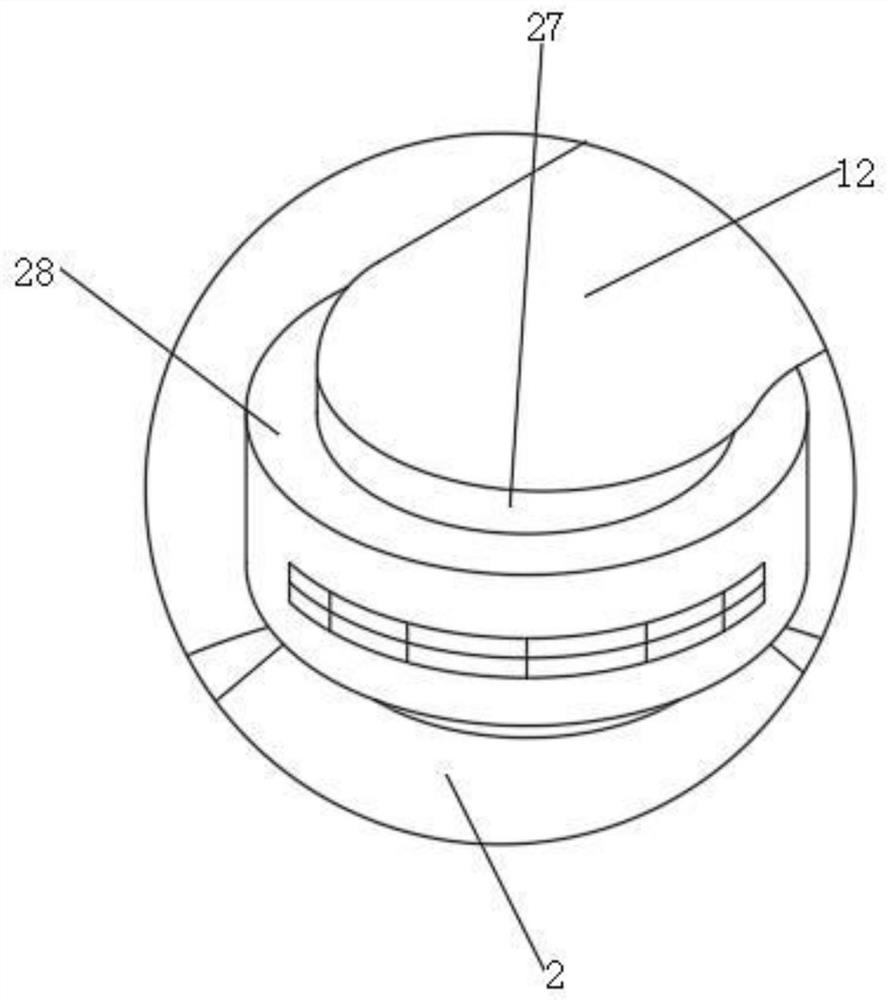

[0058] Such as Figure 5-Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that one side of the air compression tower 2 is provided with a first observation hole 21, and the first toughened glass layer 22 is sealed and installed in the first observation hole 21, and the air purification tower A second observation hole 61 is opened on one side of the opening 6, and a second tempered glass layer 62 is hermetically installed in the second observation hole 61 .

[0059] By adopting the above technical scheme, the specific conditions in the air compression tower 2 can be observed through the first tempered glass layer 22 and the specific conditions in the air purification tower 6 can be observed through the second tempered glass layer 62, which is convenient for the staff to grasp the air compression The specific situation in the tower 2 and in the air purification tower 6.

Embodiment 3

[0061] Such as figure 1 and Figure 5 As shown, the difference between this embodiment and Embodiment 2 is that the bottom side of the air compression tower 2 and the bottom side of the air purification tower 6 are respectively provided with a first airtight door 23 and a second airtight door 66 .

[0062] By adopting the above-mentioned technical scheme, when the waste material cannot be removed at the outlet of the air compression tower 2 and the air purification tower 6, the air compression tower 2 cleans up the internal waste material by opening the first sealing door 23, and the air purification tower 6 cleans up the internal waste material by opening the second sealing door. Door 66 to clear the interior of the waste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com