Rapid and automatic packaging device for PCBs (printed circuit boards)

A PCB board, fast technology, applied in the field of PCB board fast automatic packaging device, can solve the problems of heavy labor, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

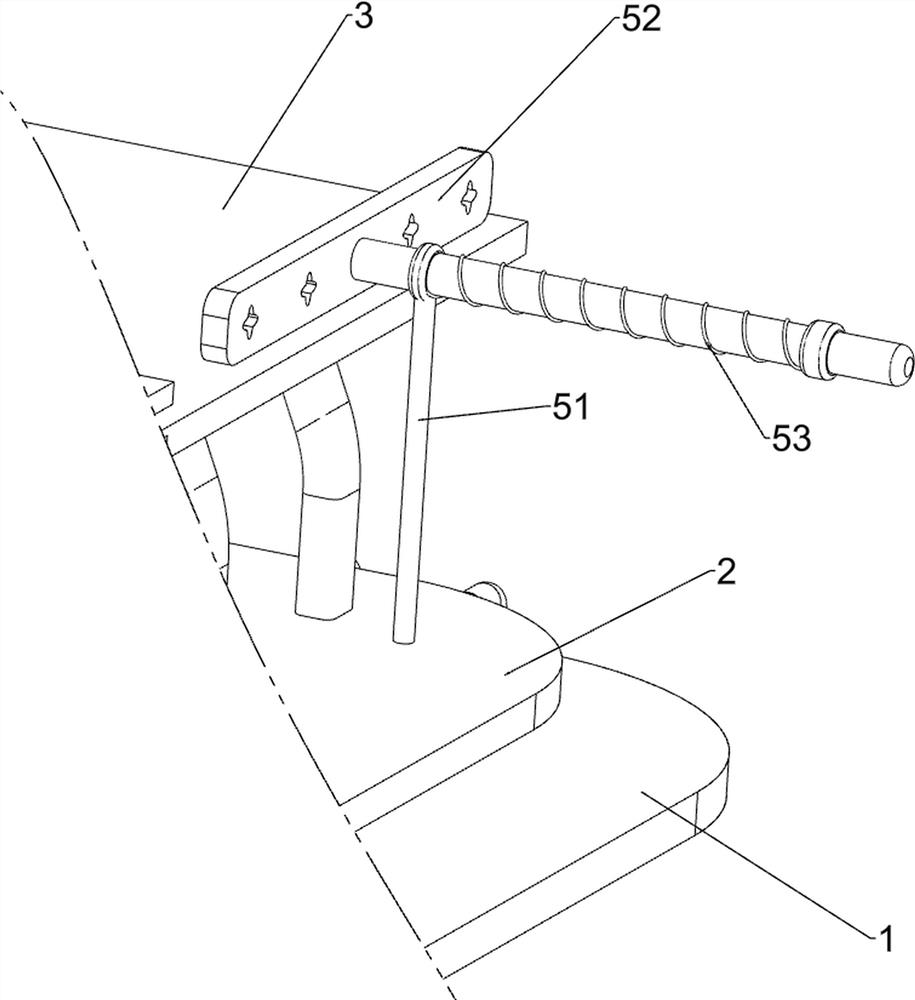

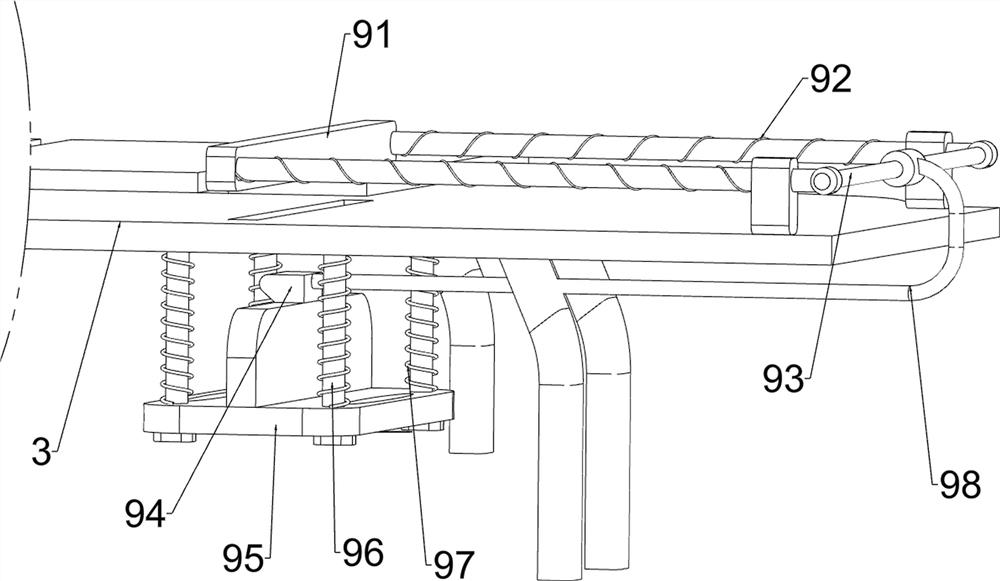

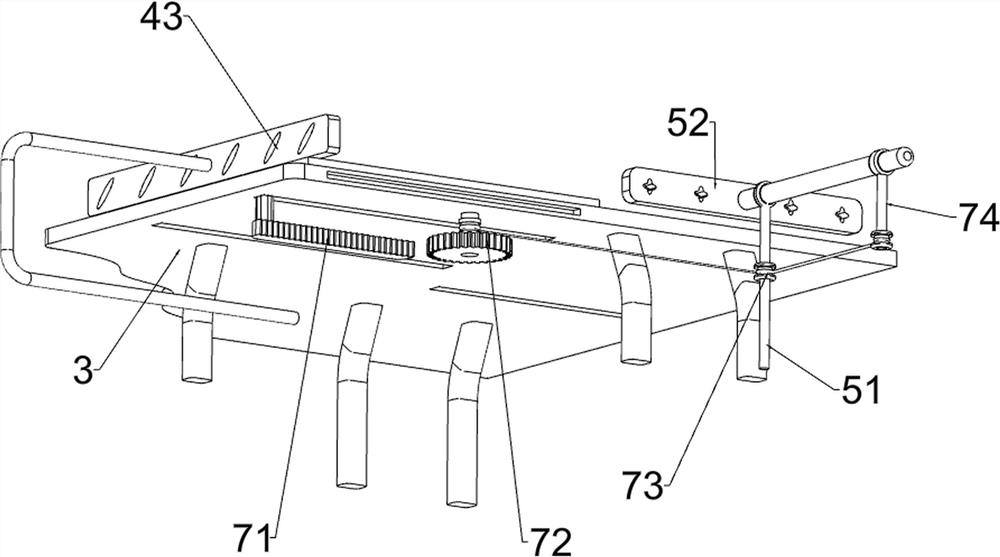

[0058] A fast automatic packaging device for PCB boards, such as Figure 1-3 As shown, it includes a first fixing part 1, a second fixing part 2, a third fixing part 3, a pushing mechanism 4 and a discharging mechanism 5, the first fixing part 1 is provided with a second fixing part 2, and the first fixing part 2 A third fixing part 3 is arranged between the part 1 and the second fixing part 2 , a pushing mechanism 4 is arranged on the second fixing part 2 , and a discharging mechanism 5 is arranged on the third fixing part 3 .

[0059] The pushing mechanism 4 includes a cylinder 41, a first fixed rod 42 and a first push plate 43, the middle rear side of the second fixed part 2 is provided with the first fixed rod 42, and the middle of the second fixed part 2 is provided with a cylinder 41, The rear portion of the cylinder 41 is provided with a first push plate 43 , the first push plate 43 is slidably connected to the first fixing rod 42 , and the first push plate 43 is slidab...

Embodiment 2

[0063] On the basis of Example 1, such as Figure 4-7 As shown, a clamping mechanism 6 is also included. The clamping mechanism 6 includes a splint 61, a second support rod 62, a first rod 63, a second spring 64 and a slide bar 65. Both sides are connected with two second support rods 62, the first rods 63 are connected between the horizontal second support rods 62, two sliding rods 65 are slidably connected between the first rods 63, and the longitudinal The splints 61 are connected between the sliding bars 65 , and the second springs 64 are connected between the horizontal sliding bars 65 .

[0064]When people need to pack the PCB boards, they first move the splint 61 to the outside, so that the slide bar 65 moves to the outside, so that the second spring 64 is stretched, and then the PCB is placed between the splints 61, so that the bottom The PCB board falls onto the third fixing part 3, and then let go. Under the action of the second spring 64, the clamping plate 61 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com