Transformer processing and packaging device

A transformer and packaging technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of low efficiency and slow processing speed, and achieve the effect of high speed and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

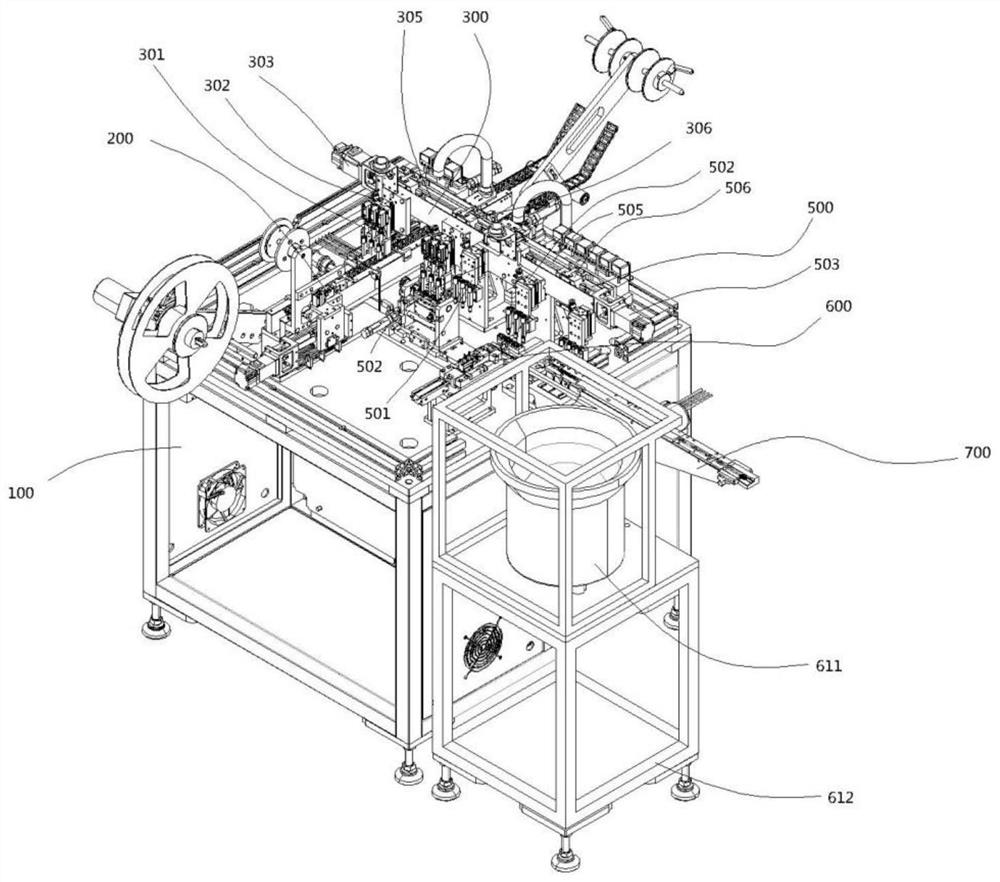

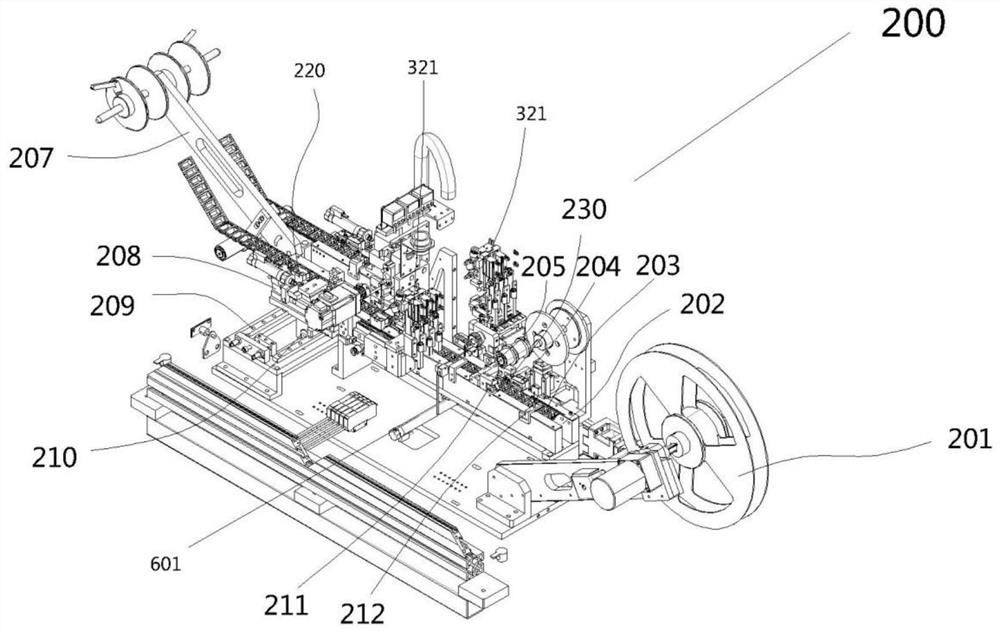

[0025] As shown in the figure, the transformer processing and packaging device includes a workbench 100, a feed line 700 is installed on the right side of the workbench 100, and a protective sleeve insertion mechanism 600 is installed at the discharge of the feed line 700, and a material transfer mechanism 500 and the feeding mechanism 300 are installed on the left side of the protective cover insertion mechanism 600 , and a packaging mechanism 200 is also installed on the workbench 100 , and the packaging mechanism 200 is inserted at the bottom of the feeding mechanism 300 .

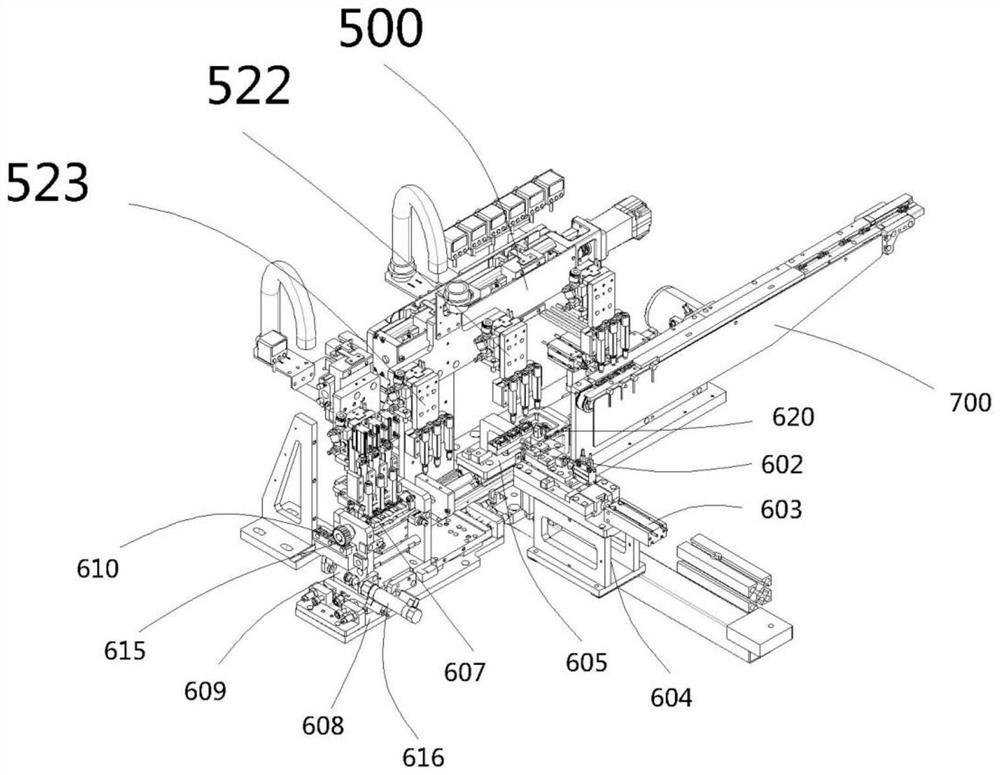

[0026] The protective cover insertion mechanism 600 includes an insertion workbench 605 installed on the workbench 100, a base one 604 is installed on the front side of the insertion workbench 605, and a cylinder one 603 is installed on the base one 604. The top of the cylinder one 603 is connected with a push block 602, and the front of the push block 602 is equipped with a plug-in feed channel 620 conn...

Embodiment 2

[0037] As shown in the figure, the transformer processing and packaging device includes a workbench 100, a feed line 700 is installed on the right side of the workbench 100, and a protective sleeve insertion mechanism 600 is installed at the discharge of the feed line 700, and a material transfer mechanism 500 and the feeding mechanism 300 are installed on the left side of the protective cover insertion mechanism 600 , and a packaging mechanism 200 is also installed on the workbench 100 , and the packaging mechanism 200 is inserted at the bottom of the feeding mechanism 300 .

[0038] The protective cover insertion mechanism 600 includes an insertion workbench 605 installed on the workbench 100, a base one 604 is installed on the front side of the insertion workbench 605, and a cylinder one 603 is installed on the base one 604. The top of the cylinder one 603 is connected with a push block 602, and the front of the push block 602 is equipped with a plug-in feed channel 620 conn...

Embodiment 3

[0045] As shown in the figure, the transformer processing and packaging device includes a workbench 100, a feed line 700 is installed on the right side of the workbench 100, and a protective sleeve insertion mechanism 600 is installed at the discharge of the feed line 700, and a material transfer mechanism 500 and the feeding mechanism 300 are installed on the left side of the protective cover insertion mechanism 600 , and a packaging mechanism 200 is also installed on the workbench 100 , and the packaging mechanism 200 is inserted at the bottom of the feeding mechanism 300 .

[0046] The protective cover insertion mechanism 600 includes an insertion workbench 605 installed on the workbench 100, a base one 604 is installed on the front side of the insertion workbench 605, and a cylinder one 603 is installed on the base one 604. The top of the cylinder one 603 is connected with a push block 602, and the front of the push block 602 is equipped with a plug-in feed channel 620 conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com