Automatically shifting multi-speed gear transmission

A technology of gear transmission and automatic shifting, applied in the direction of gear transmission, belt/chain/gear, transmission, etc., can solve the problems of easy slippage, high maintenance cost and high requirement of manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

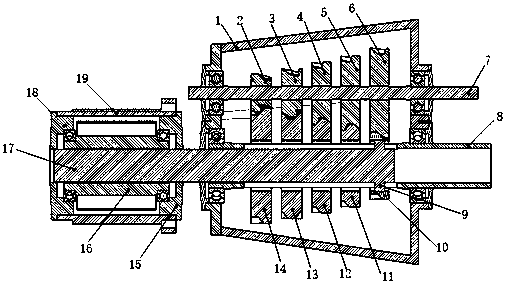

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

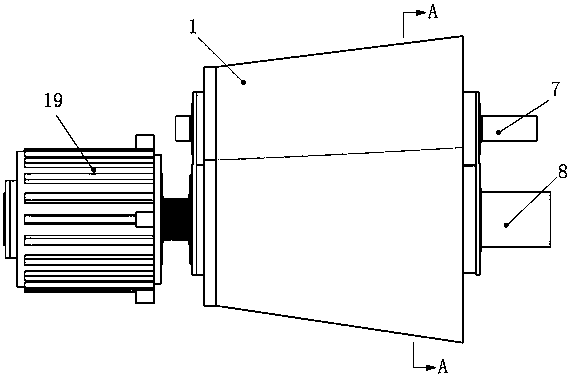

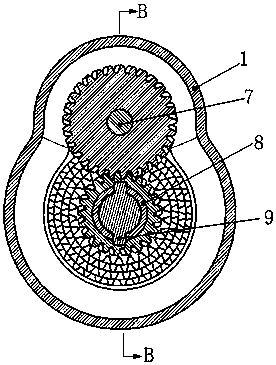

[0019] Such as figure 1 , image 3 , Figure 4 , a multi-stage gear transmission with automatic shifting, including five pairs of cylindrical gear sets, an input shaft 7, an output shaft 8, a direct-acting servo push rod and a housing 1; the housing 1 is fixedly connected to the frame , the input shaft 7 and the output shaft 8 are parallel to each other, and are respectively connected to both ends of the housing 1 through bearings; the direct-acting servo push rod is a servo direct drive device composed of an AC servo motor and a screw nut mechanism, wherein the AC servo The motor rotor 16 of the motor is in the form of a hollow shaft with an internal thread through hole, and the internal thread is exactly the nut in the screw nut mechanism. The two ends of the motor rotor 16 are respectively supported in the motor front end cover 15 and the motor rear end cover 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com