Camera three-dimensional holder with semi-arc-shaped sliding rail and working method thereof

A semi-circular arc-shaped, three-dimensional pan-tilt technology, which is applied in the direction of machine platforms/supports, supporting machines, mechanical equipment, etc., can solve the problems of weak load-bearing capacity, dust entering, nodding, etc. The effect of lateral angle adjustment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

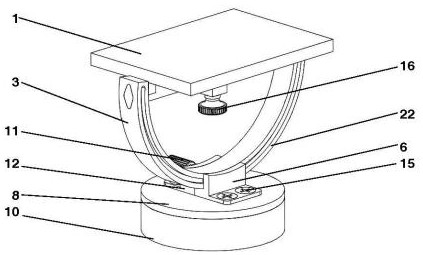

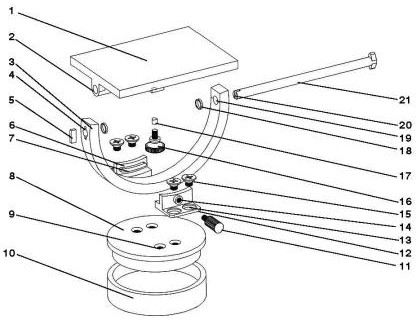

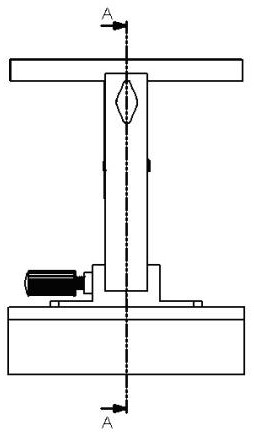

[0022] The camera three-dimensional pan / tilt with semi-arc slide rails of the present invention includes a lower platform 8 and two opposite support blocks (the first support block 6 and the second support block 12) fixed on the upper surface of the lower platform 8, the two A semicircle-arc slide rail 3 is provided for spacing between two oppositely arranged support blocks. The cross-sectional shape of the semicircle-arc slide rail 3 can be a rectangle. For the first screw 11 of the slide rail, the second support block 12 is provided with a first screw hole 14, and the first screw 11 is locked in the first screw hole.

[0023] The opening end of the semicircular slide rail 3 is pierced with a crossbar 21 and an upper platform 1 whose bottom surface is sleeved on the crossbar 21, and the bottom surface of the upper platform 1 is provided with a second screw 16 for fastening the crossbar.

[0024] The structures of the above-mentioned two oppositely arranged support block limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com