Motor inspection device and use method thereof

A supporting device and detector technology, applied in measuring devices, mechanical gap measurement, instruments, etc., can solve the problems of lower inspection efficiency, inability to conduct a comprehensive inspection at one station, and high work intensity of workers, so as to achieve the effect of convenient inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

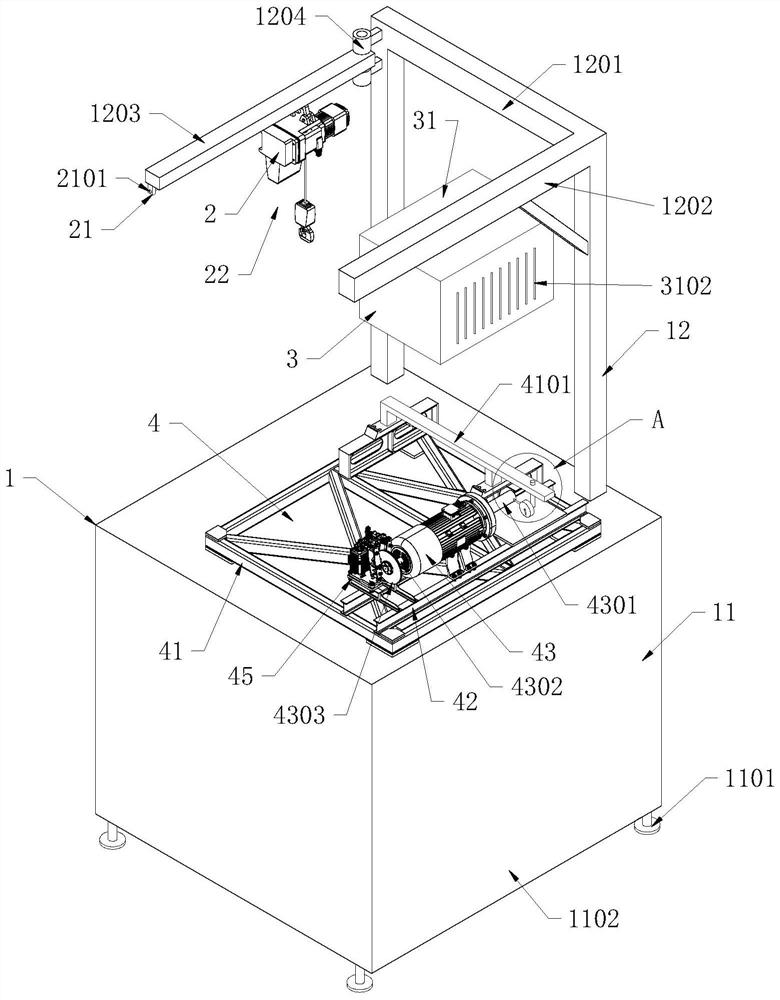

[0037] Please refer to the attached Figure 1-8, a device for motor inspection, including: a support device 1, a lifting device 2, a detection mechanism 3 and an inspection assembly 4 components.

[0038] The supporting device 1 includes a supporting box 11 and a supporting frame 12 arranged above the supporting box 11, and the supporting device 1 provided is used to support the whole device.

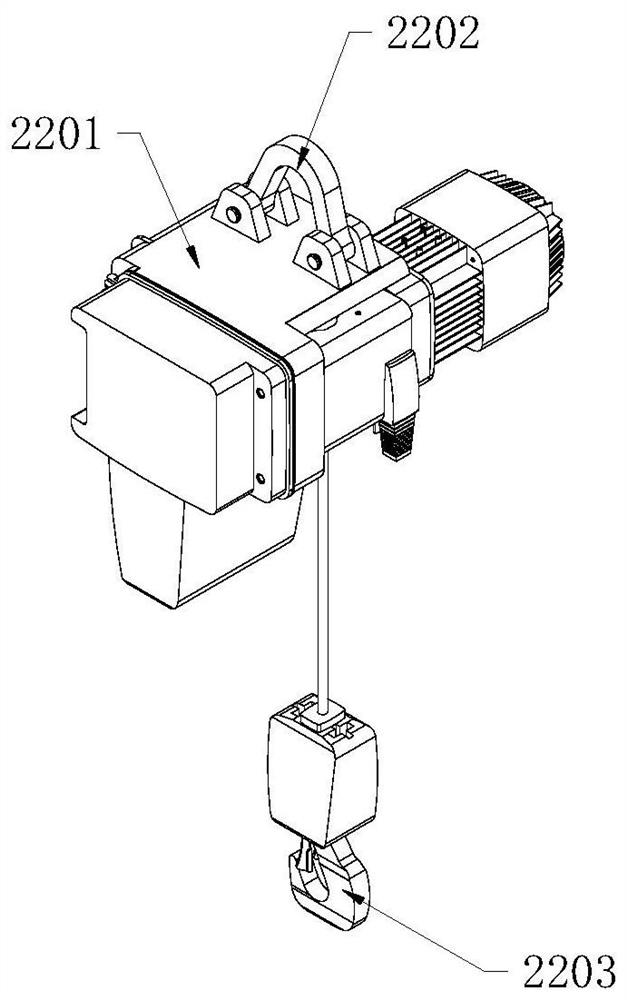

[0039] Wherein lifting device 2 comprises the mobile mechanism 21 that is arranged on support frame 12, and mobile mechanism 21 is provided with the hoisting portion 22 that is used to promote mobile motor, because the heavy weight of motor 43 adopts manual mode to carry time-consuming and laborious, and also has certain potential safety hazards, the provided lifting device 2 is used to lift the motor 43 to facilitate lifting the motor 43 to the support device 1 .

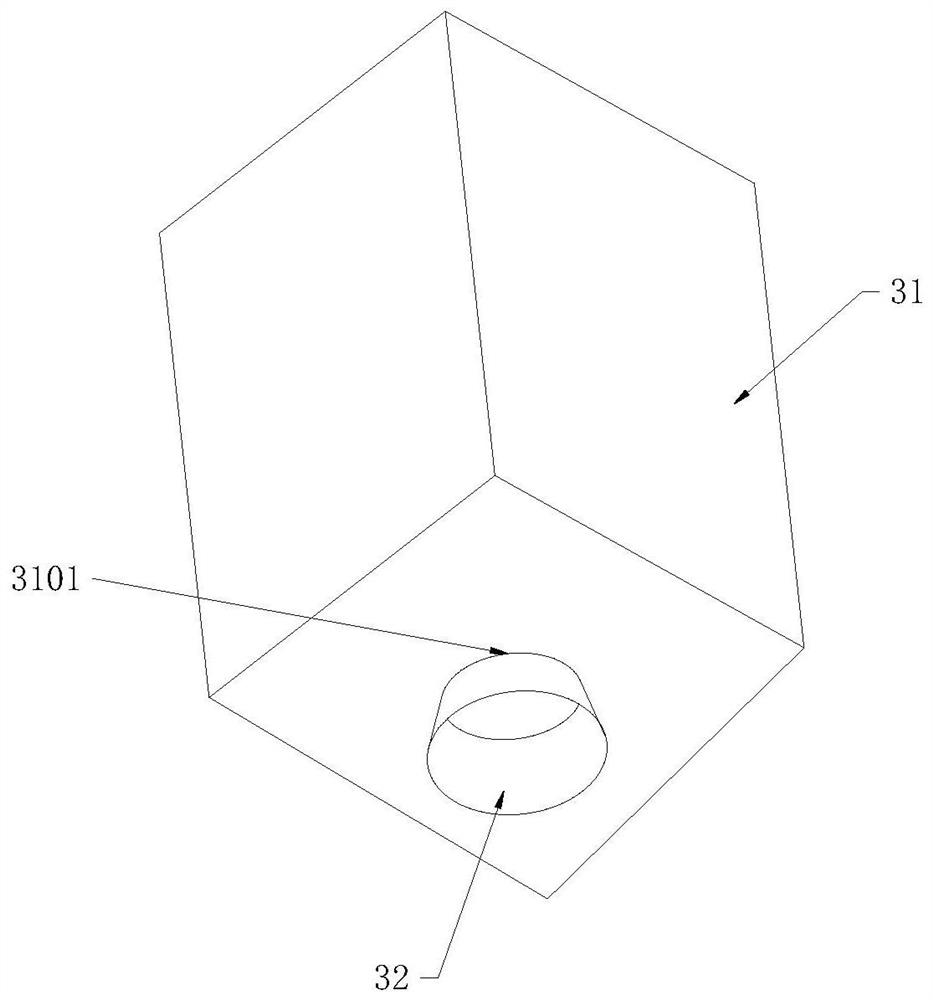

[0040] The detection mechanism 3 includes a casing 31 and an industrial camera 32 built in the casing 31 , and the detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com