Opening and drawing device of circuit board stamping die

A technology for stamping dies and circuit boards, which is applied in the direction of motor tools, hand-held tools, manufacturing tools, etc., can solve the problems of difficult molds, looseness, and decreased precision of molds, and achieves a practical, convenient, fast and convenient structure. Effort-saving opening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

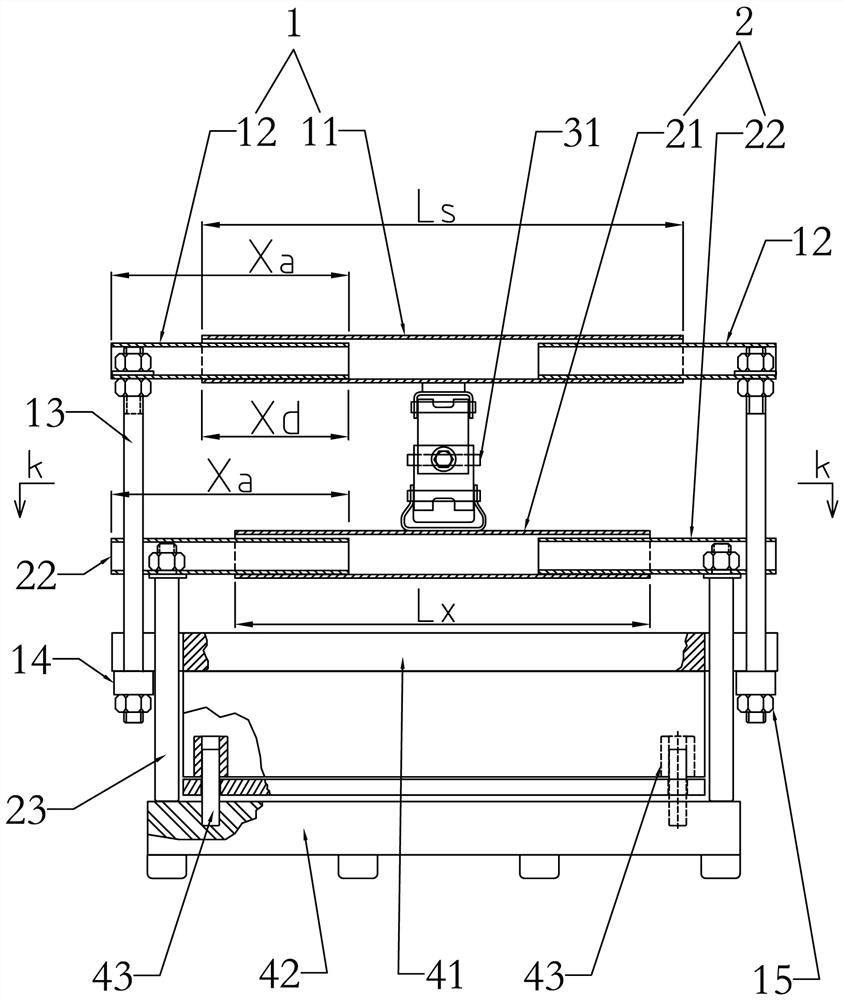

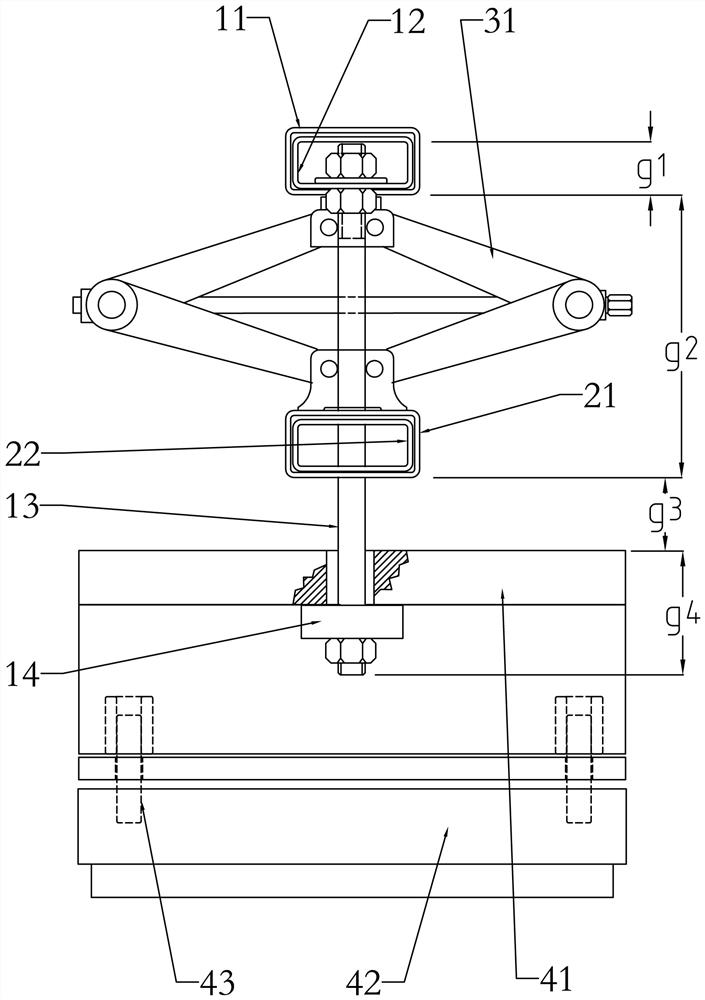

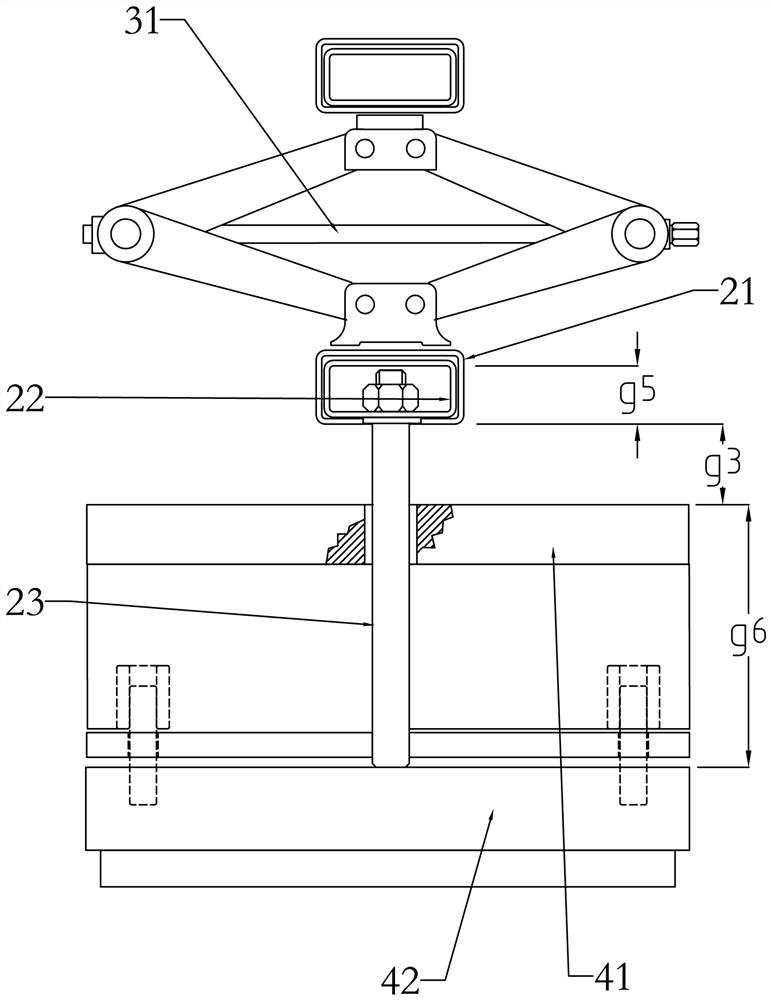

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] The drawing device of the circuit board stamping die of the present invention includes an upper cross-arm assembly 1 arranged above the upper die mounting plate 41 for pulling the upper die mounting plate 41; Correspondingly above 41, the lower cross-arm assembly 2 that supports the lower mold fixing plate 42 is provided; the jack 31 that pulls out the mold is placed between the upper cross-arm assembly 1 and the lower cross-arm assembly 2 to pull out the mould. like Figure 1 to Figure 6 Shown, comprise the elevating cross arm 11 that constitutes upper cross arm assembly 1, the upper pulling tube 12 that inserts respectively at lifting cross arm 11 two ends, the outer end 90 ° device pulling rod 13 of two upper pulling tubes 12. The pulling rod 13 is a double-ended screw, the thread length of the upper end is configured to be clamped by double nuts on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com