A pull-top and its pop-top can

A technology for pop-top cans and lids, applied in the field of pop-top can processing, can solve problems such as inability to effectively tear open the opening sheet, inconvenient drinking of the can body beverage, and tearing of the opening sheet 011. The effect of denaturation and ensuring the ability to withstand pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

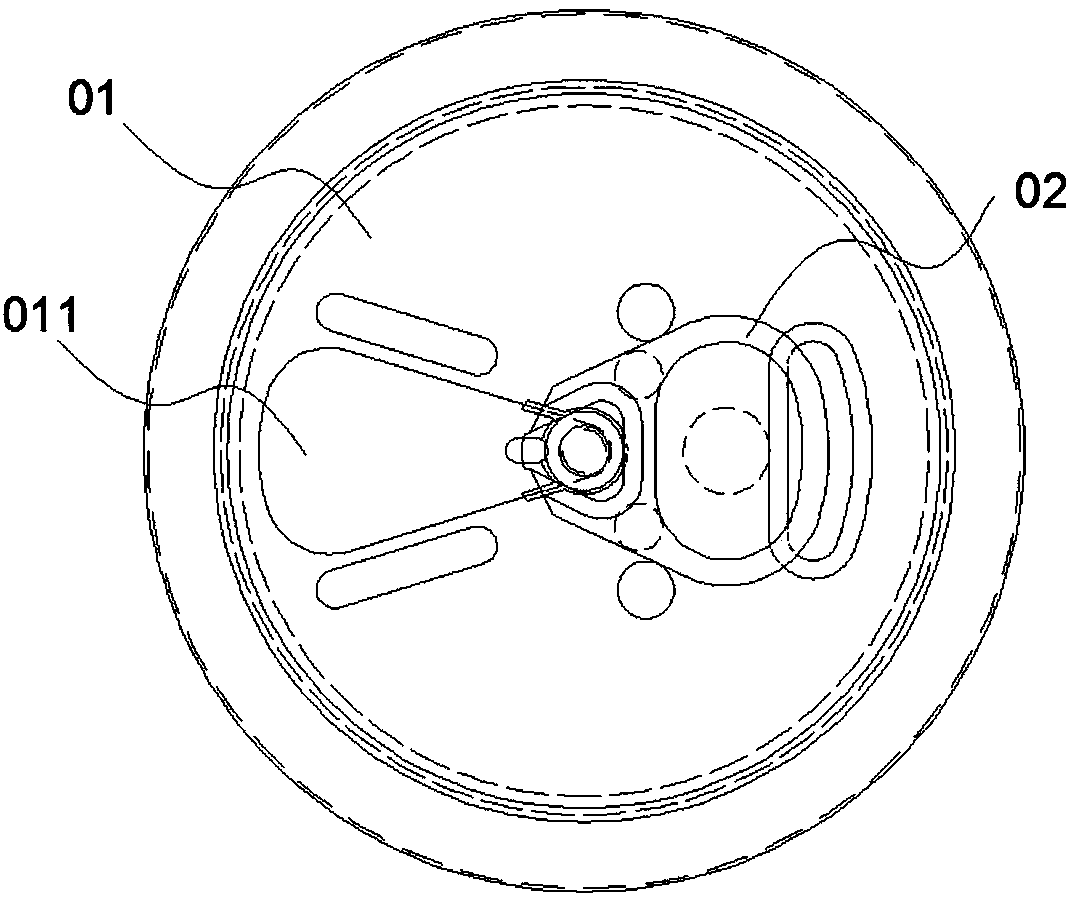

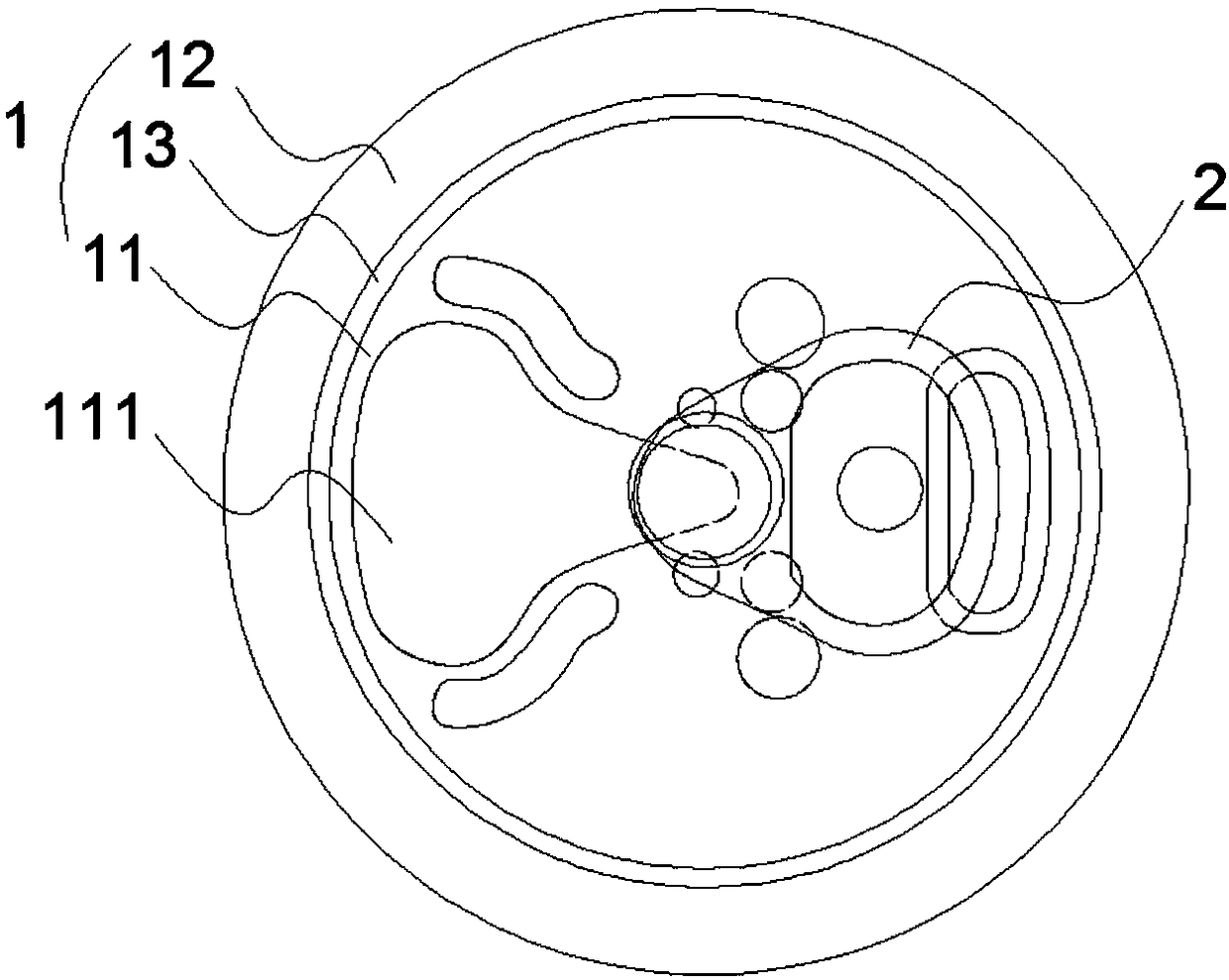

[0025] see figure 2 , which is a schematic diagram of the structure of the embodiment of the pull cover of the present invention. The pull-out cover of this embodiment includes a cover body 1 and a pull ring 2 riveted on the cover body. The cover body 1 includes a cover surface 11 , a cover frame 12 and a collar 13 ; the cover surface 11 and the cover frame 12 are joined by a recessed collar 13 . The top surface of the cover surface 11 is provided with an opening piece 111 extending from the center of the cover surface to the edge of the cover surface, and the pull ring 2 is riveted to the opening piece 111 at the center of the cover surface 11 .

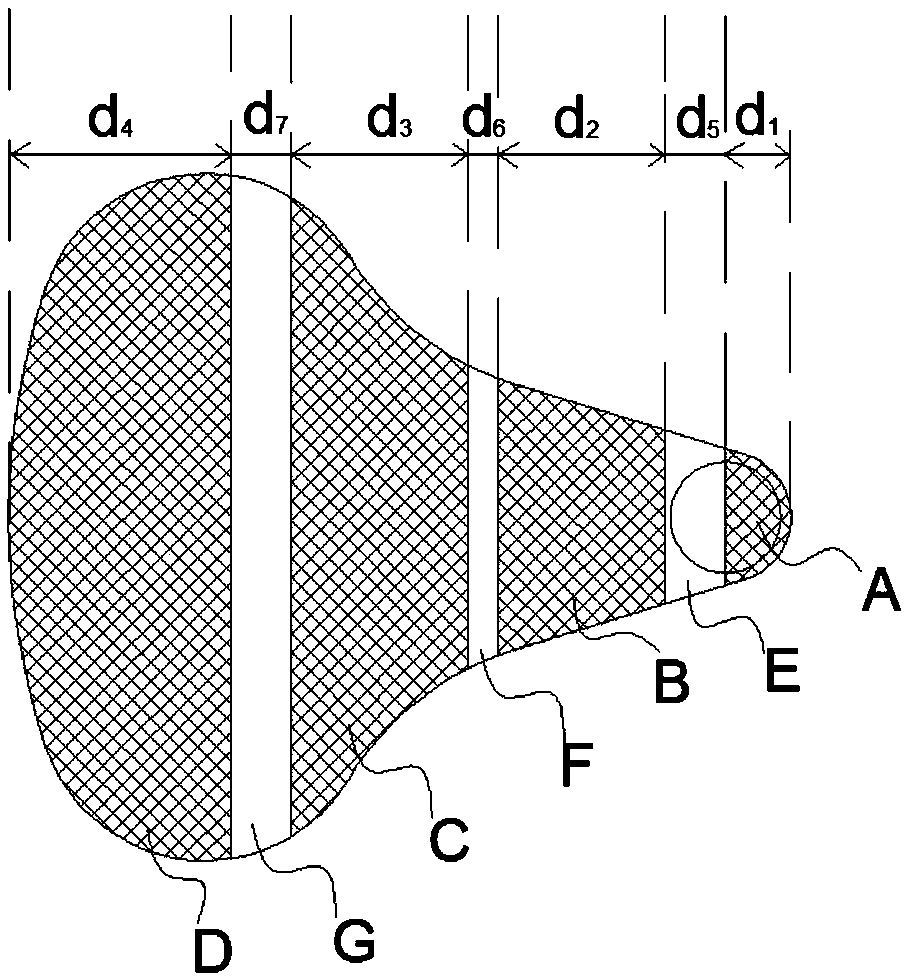

[0026] see image 3 , which is figure 2 Schematic diagram of the structure of the opening sheet shown. The opening piece 111 includes a tear opening part A, a tear part B, a tear part C and a detachment part D distributed sequentially from the center of the cover to the edge of the cover, and there is a thickness difference be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com