Concrete one-way injection device and injection method for prefabricated part connecting pipeline

A technology for connecting pipes and prefabricated components, which is applied in the direction of building construction, construction, and building materials processing, etc. It can solve the problems of increasing safety hazards, increasing construction joints, and reducing the use time of prefabricated components, so as to prevent insufficient grout and realize The effect of one-way circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

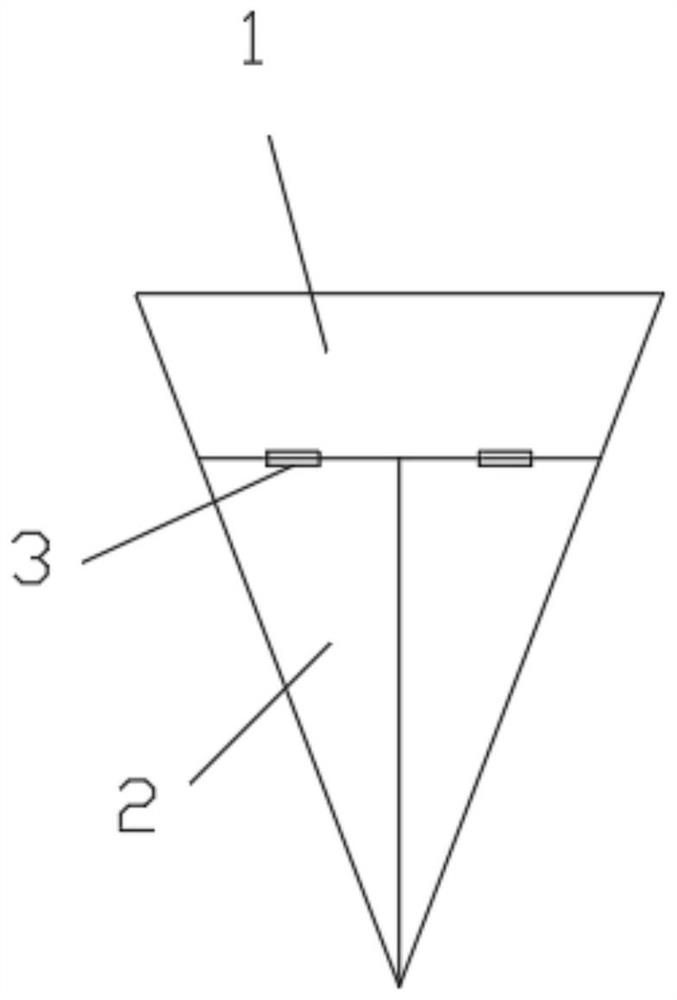

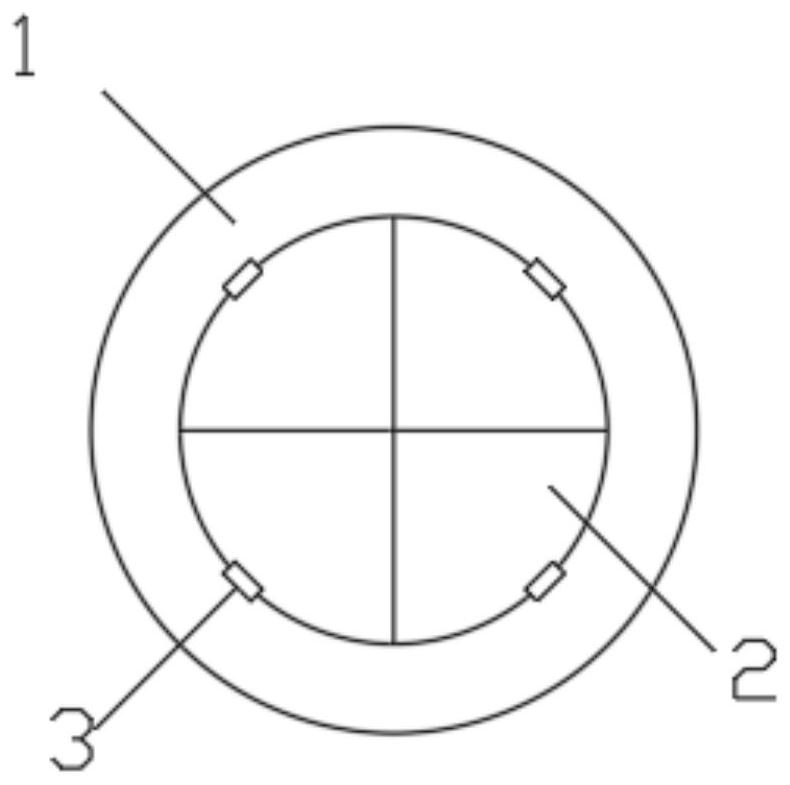

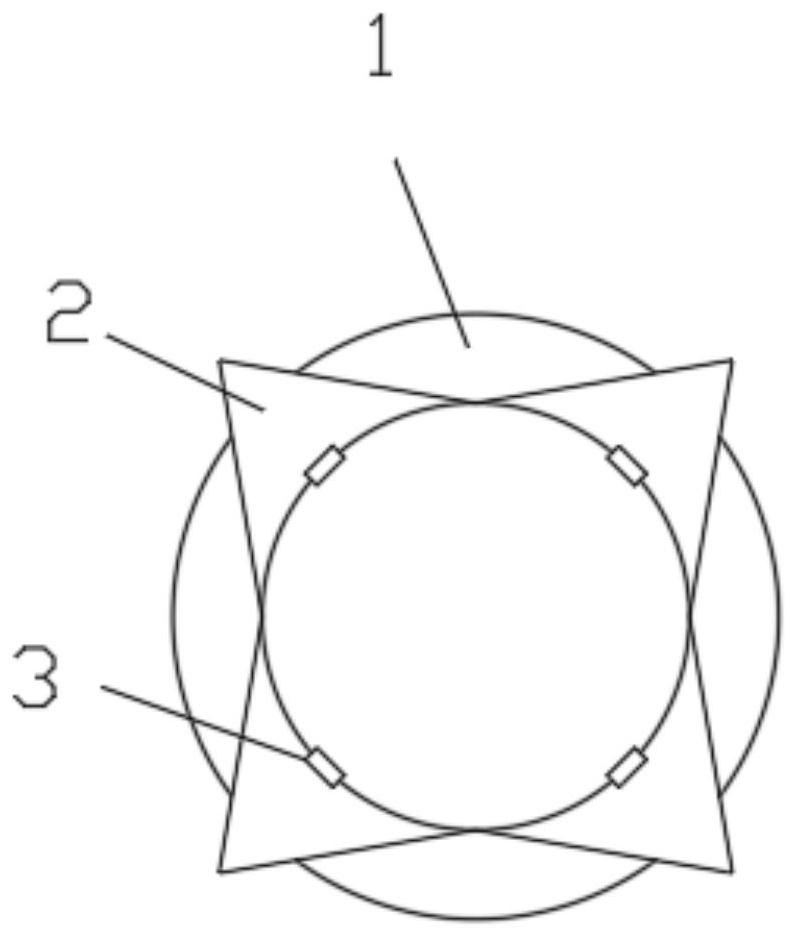

[0022] Such as figure 1 , figure 2 , image 3 As shown, in this embodiment, a prefabricated component is connected to a pipe concrete one-way injection device, including a feed pipe 1, a number of movable blades 2 that are rotatably arranged at one end of the feed pipe 1 and can be closed, and the feed pipe 1 and the movable vane 2 are connected with a reset structure 3 for making the movable vane 2 retracted.

[0023] During grouting, the feed pipe 1 is installed on the grouting port, the movable vane 2 is stretched into the grouting hole, the pipe used for grouting is connected to the feed pipe 1, and then the grouting starts. Under the action of the pressure of the slurry, the movable blades 2 are opened so that the slurry can flow smoothly. After the grouting is stopped, under the action of the reset structure 3, the movable blade 2 returns inward, thereby closing the feed pipe 1, which can prevent the backflow or leakage of the grout, and maintain the grouting pressur...

Embodiment 2

[0026] On the basis of the above embodiments, in this embodiment, the adjacent movable blades 2 can be sealed and connected, so as to increase the sealing strength between the movable blades 2 and the movable blades 2 after the movable blades 2 are closed, so as to prevent the slurry from leaking.

[0027] In this embodiment, the reset structure 3 uses a leaf spring. Utilize the pressure of grout to overcome the elastic force of spring leaf, make movable vane 2 open, after stopping grouting, spring leaf can drive movable vane 2 to draw in when itself recovers.

[0028] In this embodiment, the movable blade 2 is a part of a conical shape, and several movable blades 2 can be combined to form a complete conical shape. This avoids interfering with each other and leaving gaps when the movable blades 2 are drawn together. The conical structure formed after the movable vanes 2 are folded can maintain its sealing performance, and the conical surface bears the pressure of the slurry, ...

Embodiment 3

[0031] On the basis of the above embodiments, in this embodiment, a leak-proof cloth 4 is connected between the movable vanes 2 and the movable vanes 2 . After the movable blade 2 is opened, the leak-proof cloth 4 can be used to fill the gap between the movable blade 2 and the movable blade 2, and form a channel for the circulation of the slurry, so as to prevent the slurry from remaining on the movable blade 2 and cause the movable blade 2 to fail to completely gather.

[0032] In this embodiment, a leak-proof cloth 4 is connected between the movable vane 2 and the feed pipe 1 . After the movable blade 2 is opened, the gap between the leakproof cloth 4 movable blade 2 and the feed pipe 1 can be used to prevent the slurry from leaking through the gap between the movable blade 2 and the feed pipe 1, or remaining in the gap between the movable blade 2 and the feed pipe 1. The gap between the feed pipes 1 causes the movable blades 2 to fail to draw in completely.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com