A kind of self-heating vibrator used for concrete pounding

A technology of concrete and vibrating rods, which is applied in the field of concrete vibrating, which can solve the problems of rapid heat loss and the inability of vibrating rods to be heated evenly, and achieve the effect of reducing gas and reducing the amount of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

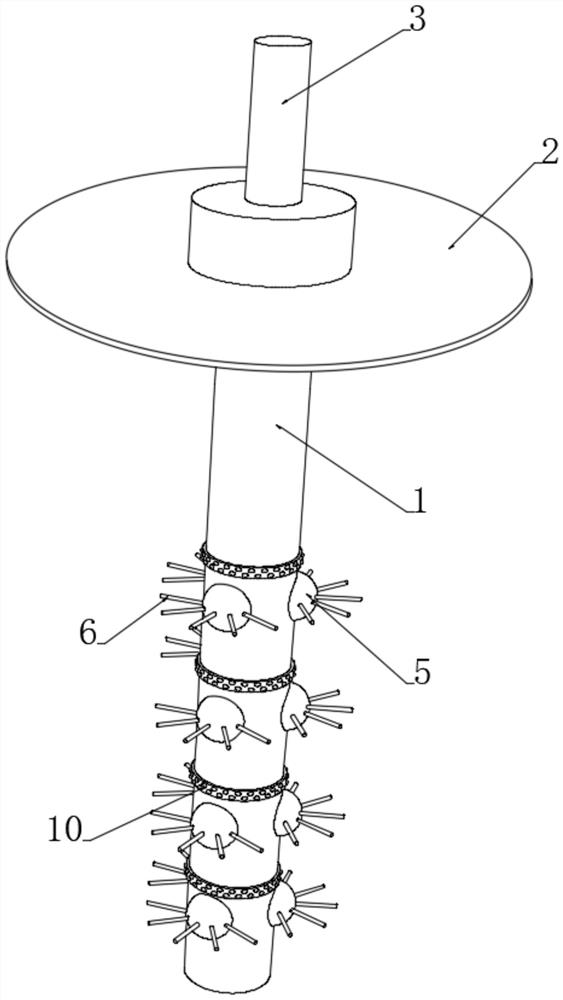

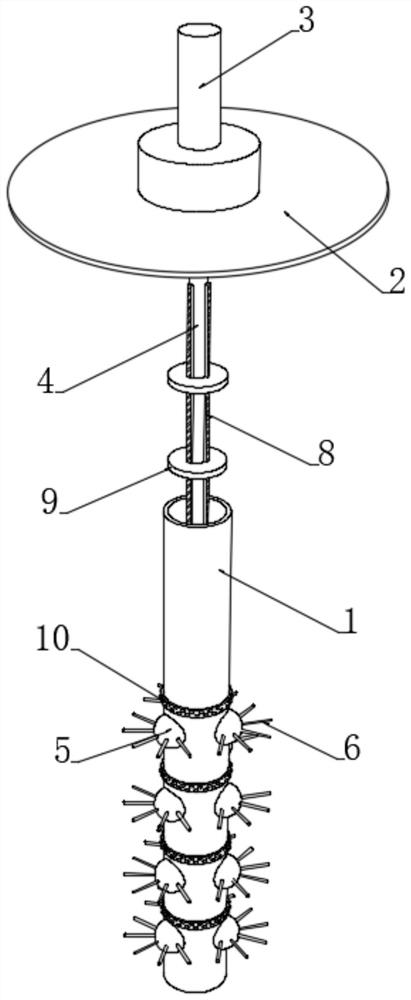

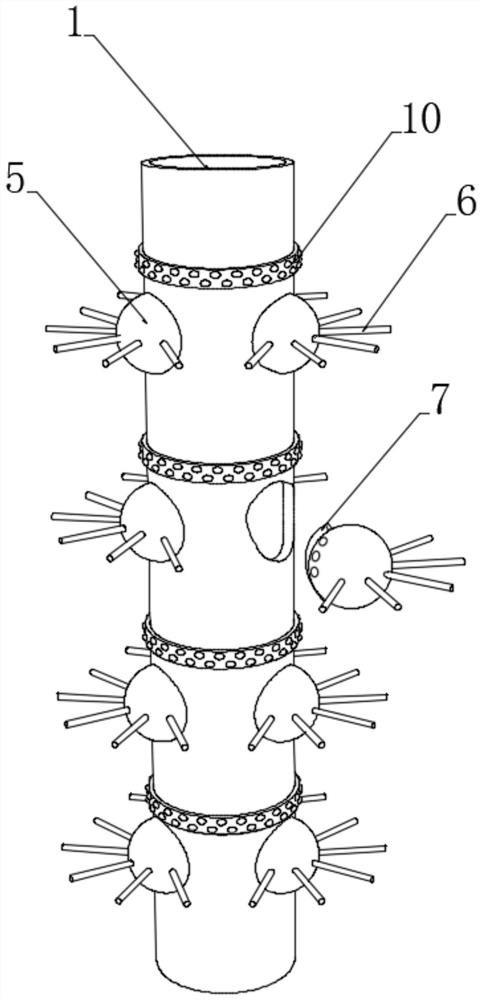

[0041] see Figure 1-4 , a self-heating vibrator used for concrete drumming, comprising a hollow rod body 1 and a support platform 2 fixedly installed on the top of the hollow rod body 1, the top of the support platform 2 is fixedly connected with an electric telescopic cylinder 3, and the electric telescopic cylinder The telescopic end of 3 runs through the support platform 2 and is fixedly connected with the lifting rod 4. The lower end of the lifting rod 4 extends to the inside of the hollow rod body 1. The outer wall of the hollow rod body 1 near the lower end is provided with multiple groups of vibrating rods in sequence from top to bottom. There are multiple balls 5 in each group of vibrating balls 5, and the multiple vibrating balls 5 are annularly distributed on the hollow rod body 1. The outer wall of the hollow rod body 1 is provided with arc-shaped grooves for the rotation and connection of the vibrating balls 5. Multiple vibration balls The inner end of the ball 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com