Hole site marking tool and method for marking hole site on assembly part

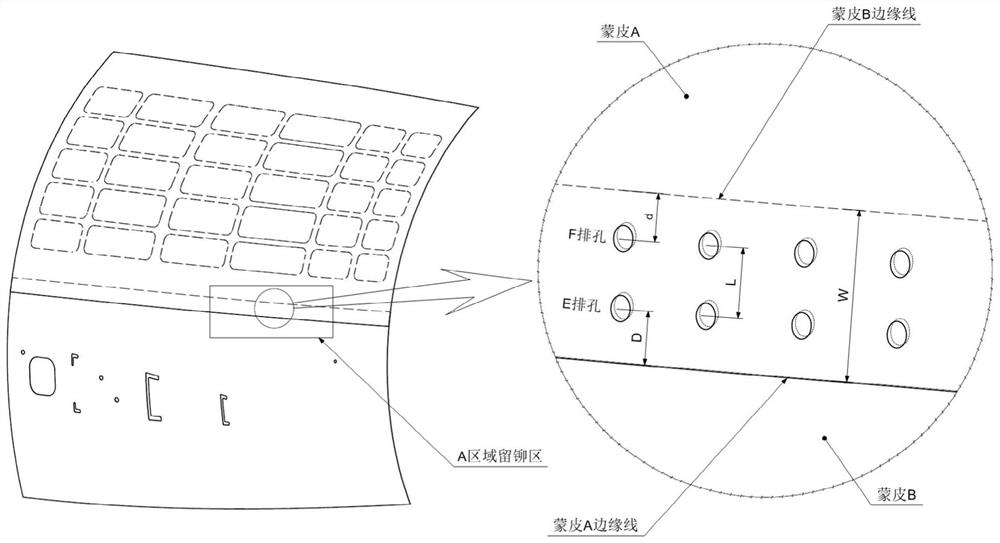

An assembly and marking technology, which is applied to the tools on the back and the assembly field of two parts on the aircraft, can solve the problem that the hole projection on the side of the assembly cannot be found, the edge distance d of the F row of holes cannot be guaranteed, and skinning cannot be realized Issues such as BF row hole marks, to achieve the effect of improving dispatch efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, so as to more clearly connect the inventive principle and beneficial technical effects of the present invention.

[0076] For the convenience of describing the present invention, the terms used herein are explained as follows:

[0077] Proximity: Approaching or facing a face or end of an assembly;

[0078] Far: The face or end away from or facing away from an assembly;

[0079] Front: In the embodiments listed in the specification, the front is the marking surface of the assembly, and in other embodiments, it can also be called the back:

[0080] Back side: In the enumerated embodiments, the side opposite to the front side can also be referred to as the front side opposite to the back side in other embodiments.

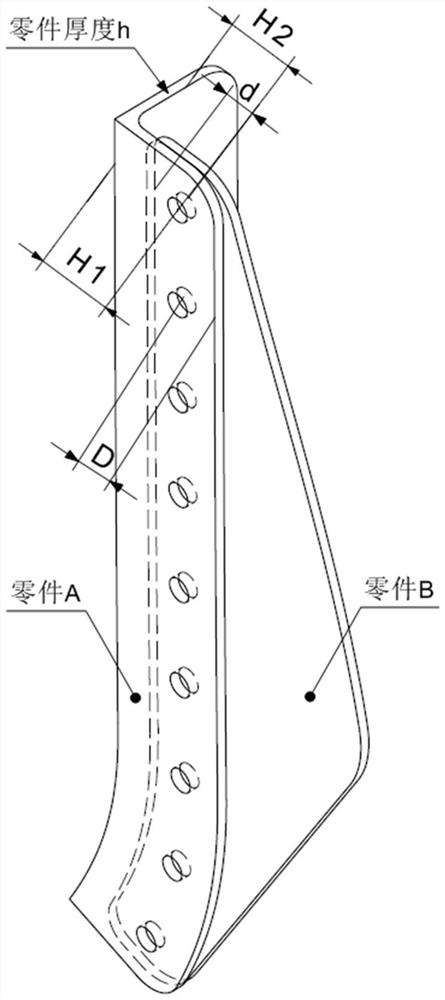

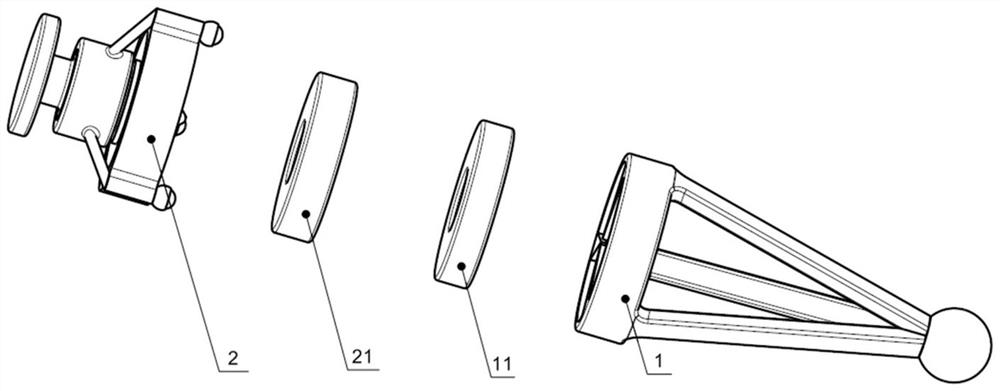

[0081] image 3 and 4 Shown is a tool for marking holes on the back of an assembly 3 according to the present invention, that is, a hole mar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com