Steel rail fat edge grinding unit

A technology for steel rails and fat edges, applied in the directions of rails, laying rails, rail maintenance, etc., can solve the problems of inability to adjust the grinding method, single grinding device strategy, etc., to improve the quality of grinding operations, improve the efficiency and quality of grinding operations, and improve operations. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

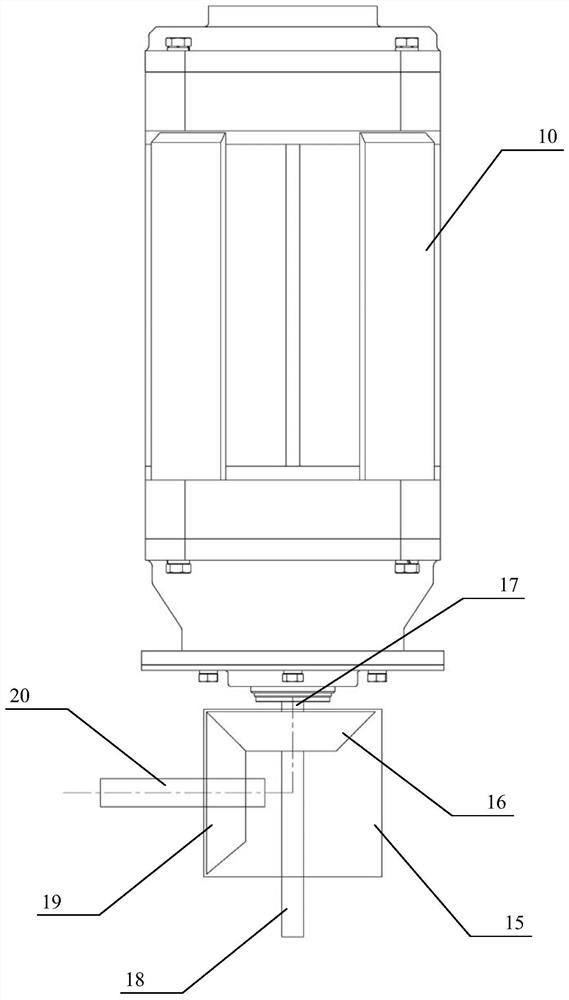

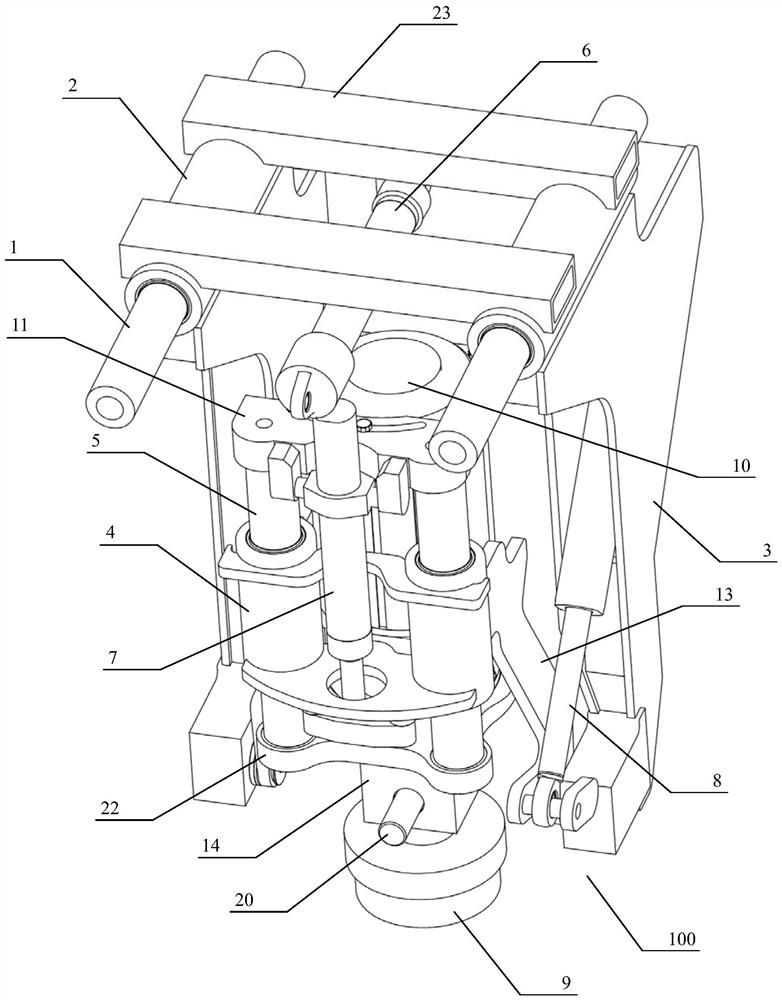

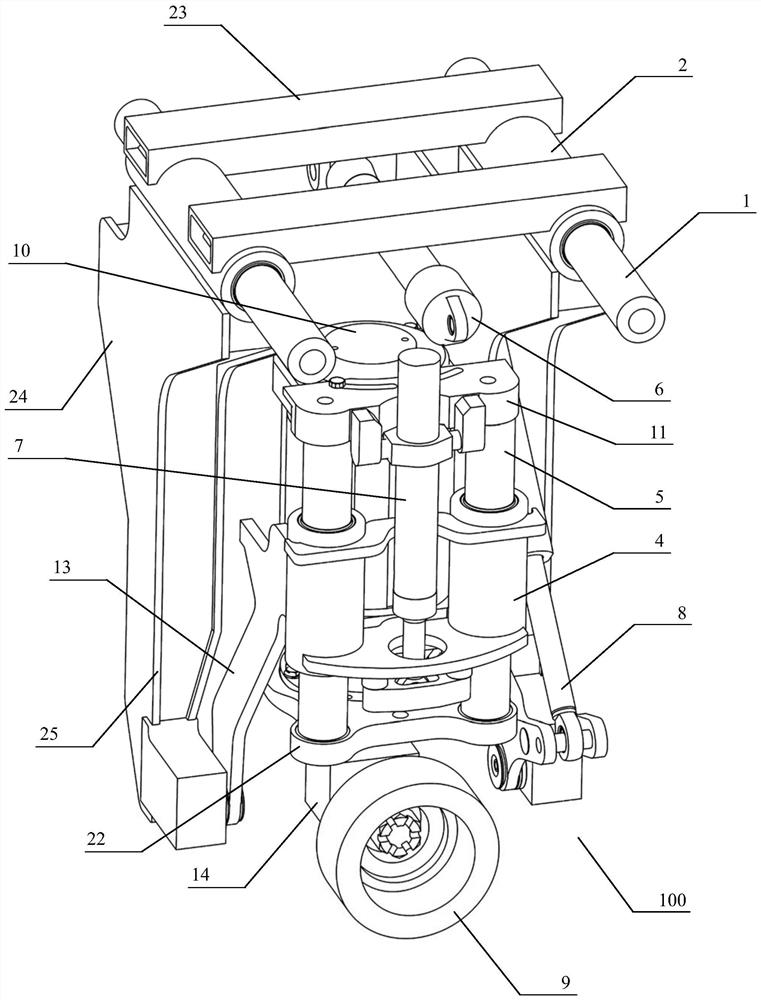

[0048] as attached figure 1 to attach Figure 5 As shown, this embodiment provides a comprehensive grinding unit for the inner side damage of the rail 40, especially for grinding the fat edge, an embodiment of the rail fat edge grinding unit 100 of the present invention, specifically comprising:

[0049] traverse mechanism;

[0050] Grinding motor 10, its output shaft links to each other with grinding wheel 9 through transmission mechanism 14, realizes the conversion of working state of grinding wheel 9 between axial grinding and tangential grinding through transmission mechanism 14;

[0051] It is used to install the grinding motor 10, and is movably connected to the grinding unit frame 3 of the traversing mechanism, and the traversing mechanism can drive the grinding motor 10 to realize the traversing operation;

[0052] The deflection mechanism connected between the grinding unit frame 3 and the grinding motor 10 can realize the deflection operation with the grinding moto...

Embodiment 2

[0063] as attached Figure 9 As shown, an embodiment of a rail grinding device 200 based on the rail fat edge grinding unit 100 shown in Embodiment 1 specifically includes:

[0064] The vehicle frame 300 arranged at the bottom of the rail grinding vehicle 400;

[0065] The traction mechanism 600 is installed between the vehicle frame 300 and the bottom of the vehicle body 500 of the rail grinding vehicle 400, and is used to transmit the traction force and drive the rail grinding unit 100 to perform grinding operations along the track;

[0066] And the rail grinding unit 100 installed on the vehicle frame 300, the rail fat edge grinding unit 100 can be configured as an end grinding unit or an arc grinding unit;

[0067] The end face grinding unit is used for targeted grinding of the fat edge on the inner side of the rail 40 , and the arc surface grinding unit is used for profile enveloping grinding of the rail 40 .

[0068]The rail grinding device 200 described in this embodi...

Embodiment 3

[0082] as attached Figure 10 As shown, an embodiment of the rail fat edge grinding unit 100 rail grinding vehicle 400 based on the rail fat edge grinding unit 100 described in embodiment 1 specifically includes:

[0083] Body 500;

[0084] And the rail grinding device 200 arranged at the lower part of the car body 500 .

[0085] Wherein, the traction mechanism 60 is installed on the bottom of the rail grinding vehicle 400 and connected with the vehicle frame 300 . One end of the lifting mechanism 70 is connected to the bottom of the rail grinding vehicle 400 , and the other end is connected to the vehicle frame 300 . The traction mechanism 60 and the lifting mechanism 70 both have one end connected to the bottom of the car body 500 of the rail grinding vehicle 400 and the other end connected to the vehicle frame 300 on which the rail grinding device 200 is installed. The traction mechanism 60 further adopts a vertical installation structure, which can solve the traction di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com