High-fidelity recycled cone

A high-fidelity, recycled paper technology, applied in the field of loudspeakers, can solve problems such as deterioration of sound pressure and frequency characteristics, failure to install and use normally, and damage to sound quality, and achieve flat sound pressure and frequency characteristics, no deterioration of THD, and improved sound quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

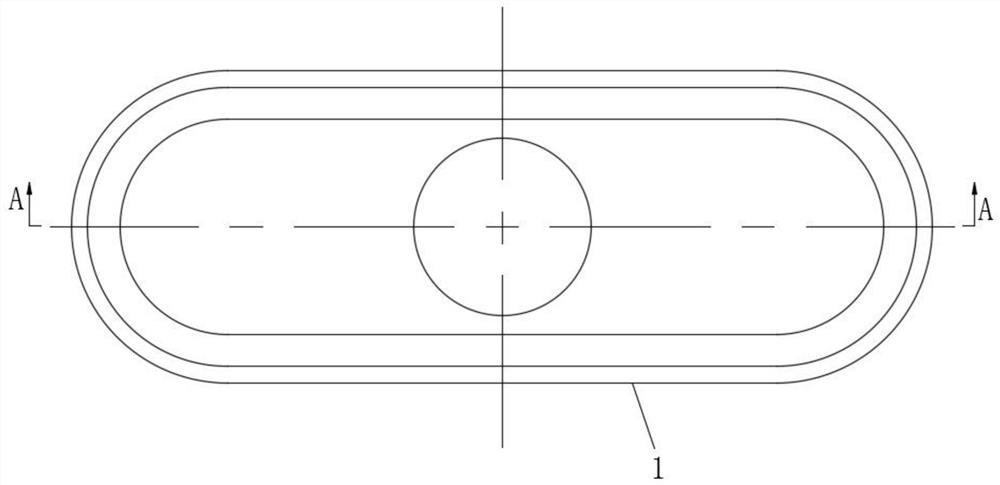

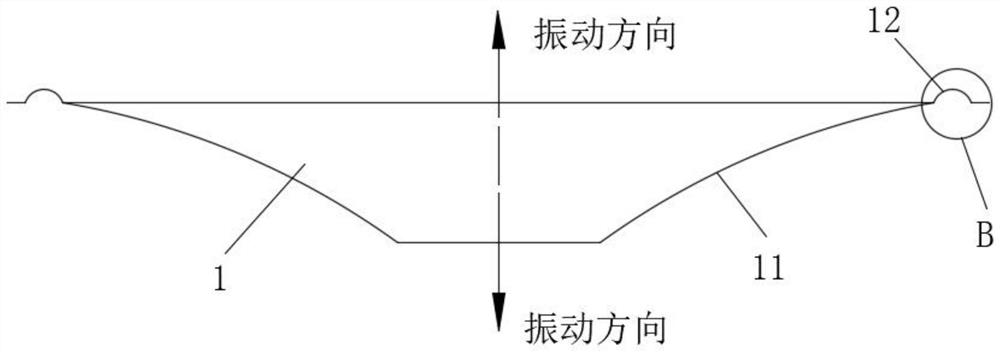

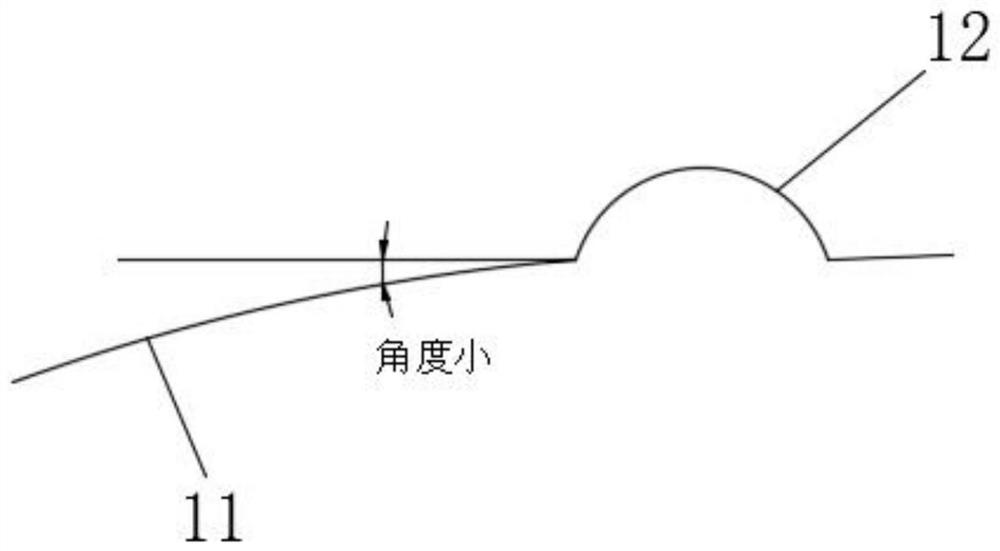

[0027] Such as Figure 6 to Figure 9 As shown, a high-fidelity recycled paper cone includes a paper cone 1 , and a continuous joint line 13 is formed between the outer periphery of the body 11 of the paper cone 1 and the ring 12 . Specifically, the space between the outer peripheral portion 11 of the body of the paper cone 1 and the ring 12 is formed by a curved or straight line with a relatively large outer peripheral angle and a continuous joining line 13 . The joint line 13 can be any one of a curve and a straight line, and if a curve is used, the joint line 13 can be any one of a parabola and an arc.

[0028] such as in Figure 6 Among them, the outer peripheral portion 11 of the carcass is formed by a curve, and the joint line 13 is formed by a curved line, and the outer peripheral portion 11 of the carcass is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com