Method for establishing communication connection between upper well completion pipe string and lower well completion pipe string

A completion pipe string and communication connection technology, applied in construction, earthwork drilling, wellbore/well components, etc., can solve the problem that the service life of the sand control screen has not reached the life cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

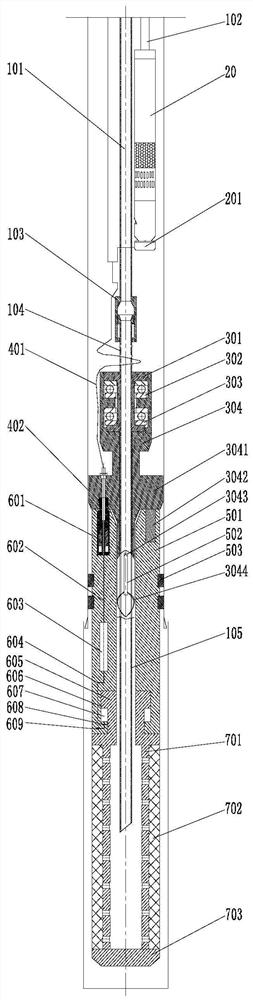

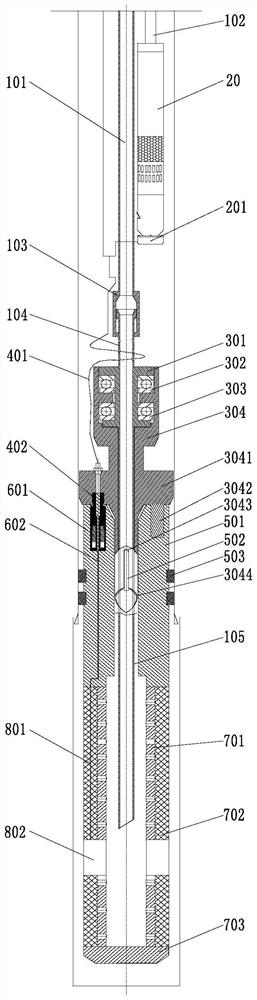

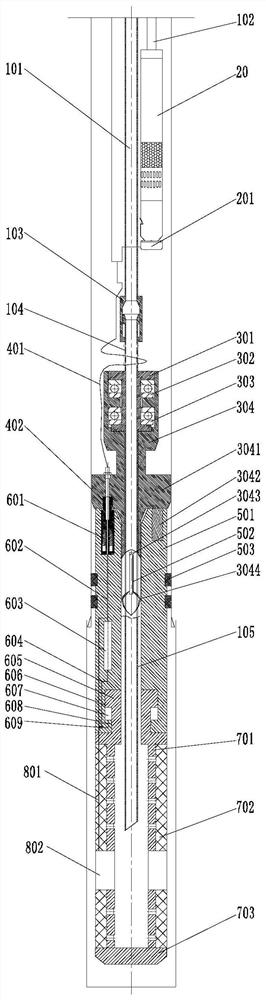

[0029] Below, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0030] Such as Figure 1-Figure 4As shown, a method for establishing a communication connection between the upper completion string and the lower completion string, the upper completion string and the lower completion string are installed in the casing, and the upper completion string is located in the lower completion string The upper end of the column, the upper completion string includes single-action directional plug-in communication components, tubing 105, electric submersible pump 20, gas tubing 101, water tubing 102, telescopic tubing 103 and perforated tubing 104, and the lower completion tubing includes The connection assembly, the sand control screen and the measurement unit, the oil pipe 105 passes through the single-action directional plug-in communication assembly and the connection assembly sequentially from top to bottom, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com