Building traffic cable energy-saving welding node used for smart city

A construction and urban technology, applied in the field of energy-saving welding nodes for building traffic cables in smart cities, can solve problems such as complex construction environment, difficult maintenance, and welding confusion, and achieve the effect of convenient use, convenient operation, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

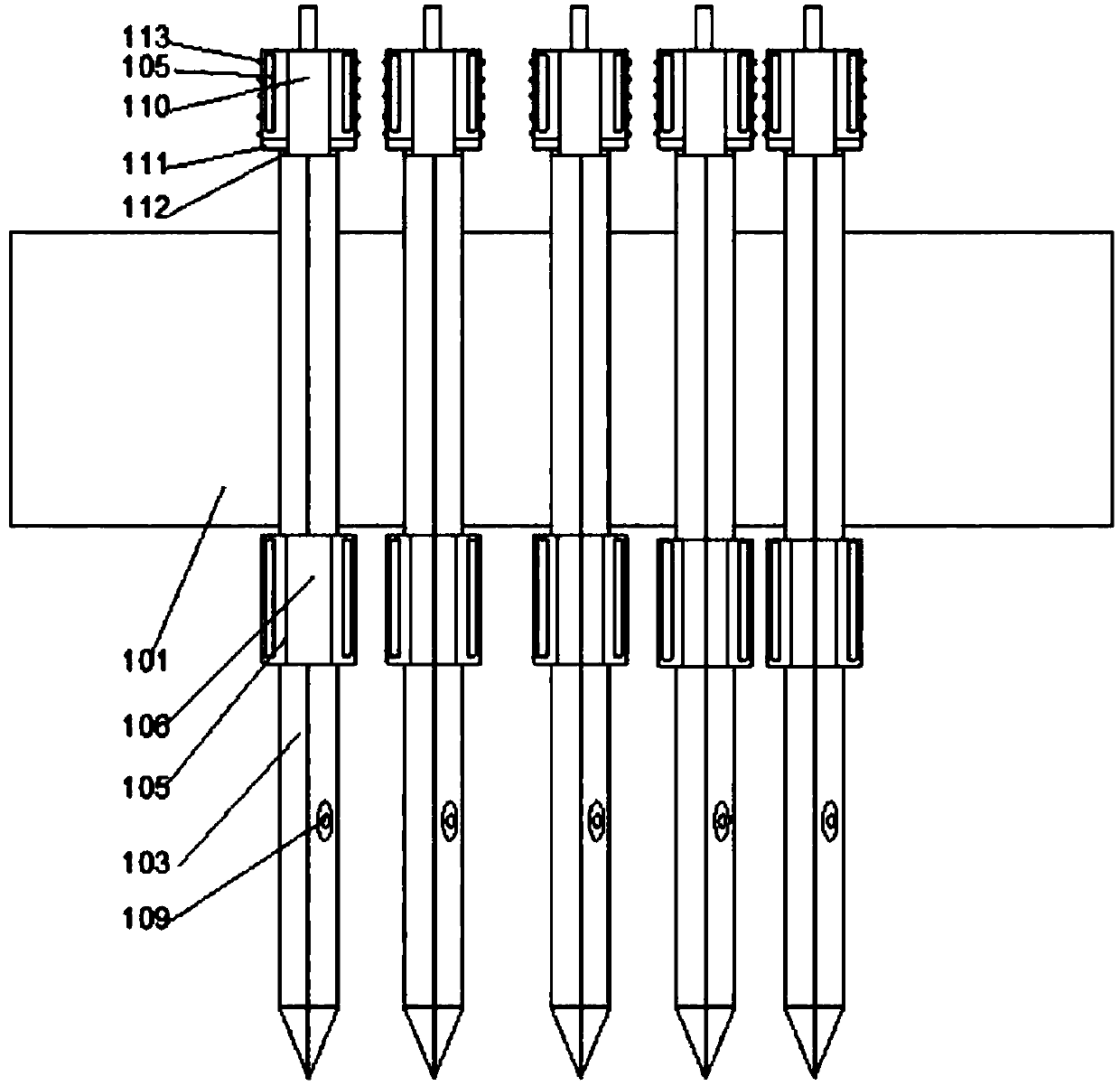

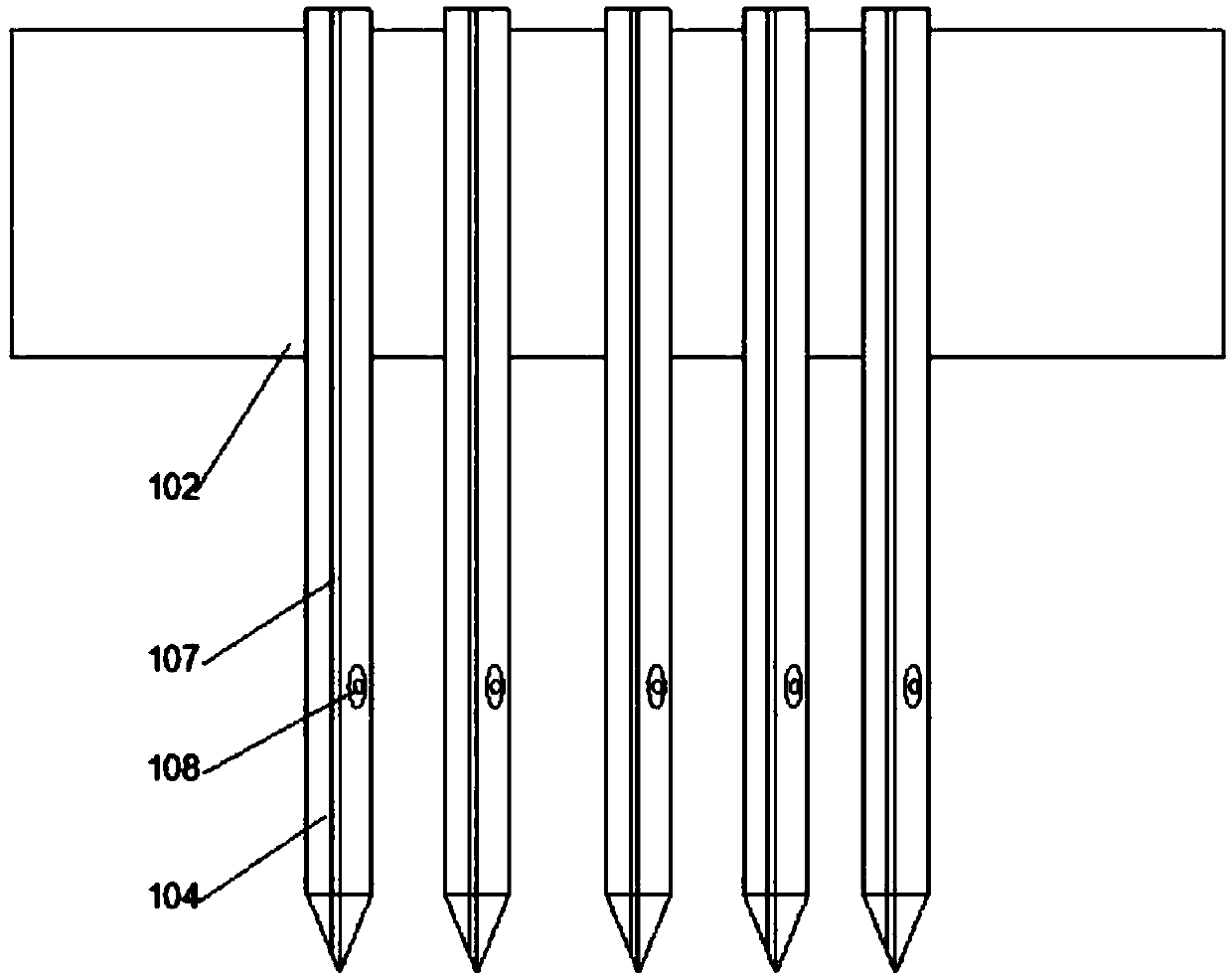

[0021] Such as figure 1 , 2 As shown, an energy-saving welding node for smart city building traffic cables includes an upper connection end 101 and a lower connection end 102. Several upper metal columns 103 are arranged in the upper connection end 101, and the upper metal The column 103 runs through the upper connection end 101, and several lower metal sleeves 104 are arranged in the lower connection end 102, and the number of the upper metal columns 103 is less than or equal to the number of the lower metal sleeves 104 , the upper metal post 103 can be plugged into the lower metal sleeve 104, and an insulating pad 105 is provided on the lower end surface of the upper connecting end 101, and the insulating pad 105 is respectively set On the upper metal pillar 103, the insulating cushion layer 105 is a hollow structure, and the insulating cushion layer 105 includes a shell structure formed by two layers of insulating cladding layers inside and outside, inside the shell struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com