Sensor type elastic washer capable of dynamically monitoring threaded connection pre-tightening force

An elastic washer, dynamic monitoring technology, applied in the direction of washer, torque/torsion measurement during tightening, instrument, etc., can solve the problems of complex external circuit, unstable detection, complex gasket structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention relates to a sensor-type elastic washer that can dynamically monitor the pretightening force of threaded connections. The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention. Obviously, the described embodiments are only the present invention. Some, but not all, embodiments of the invention.

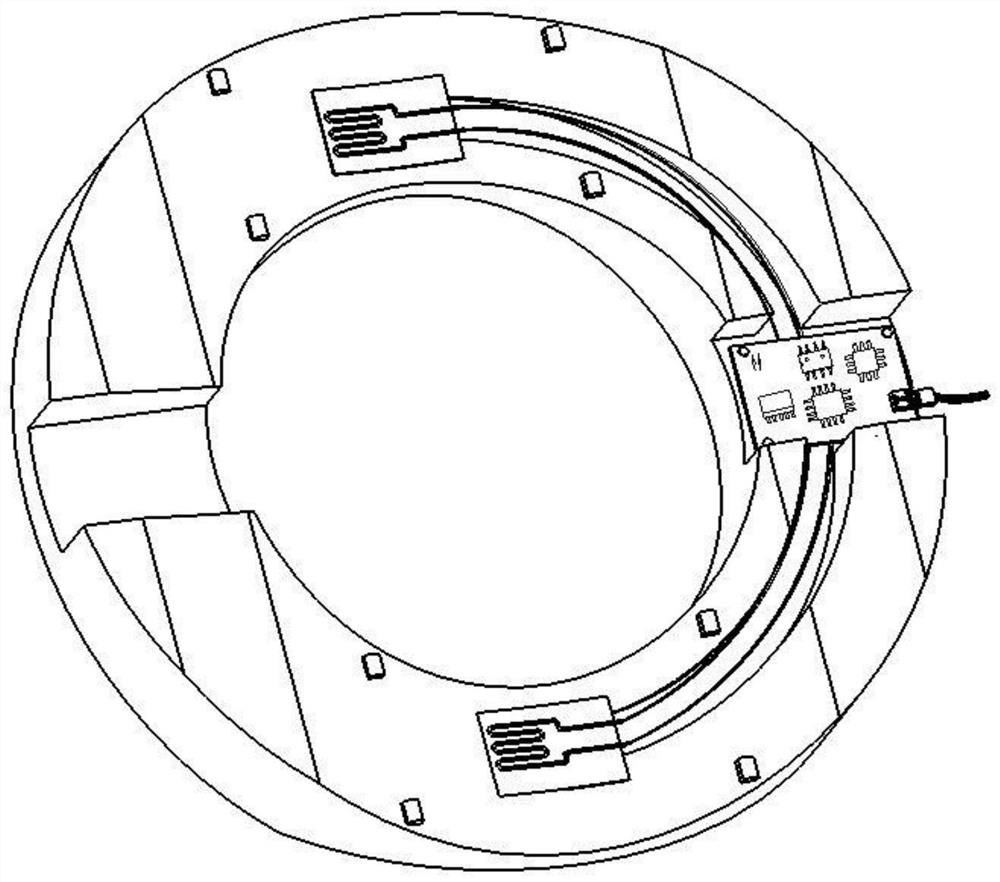

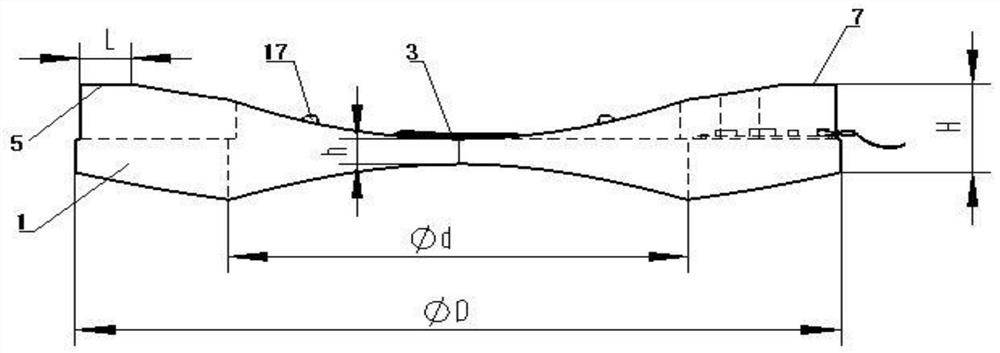

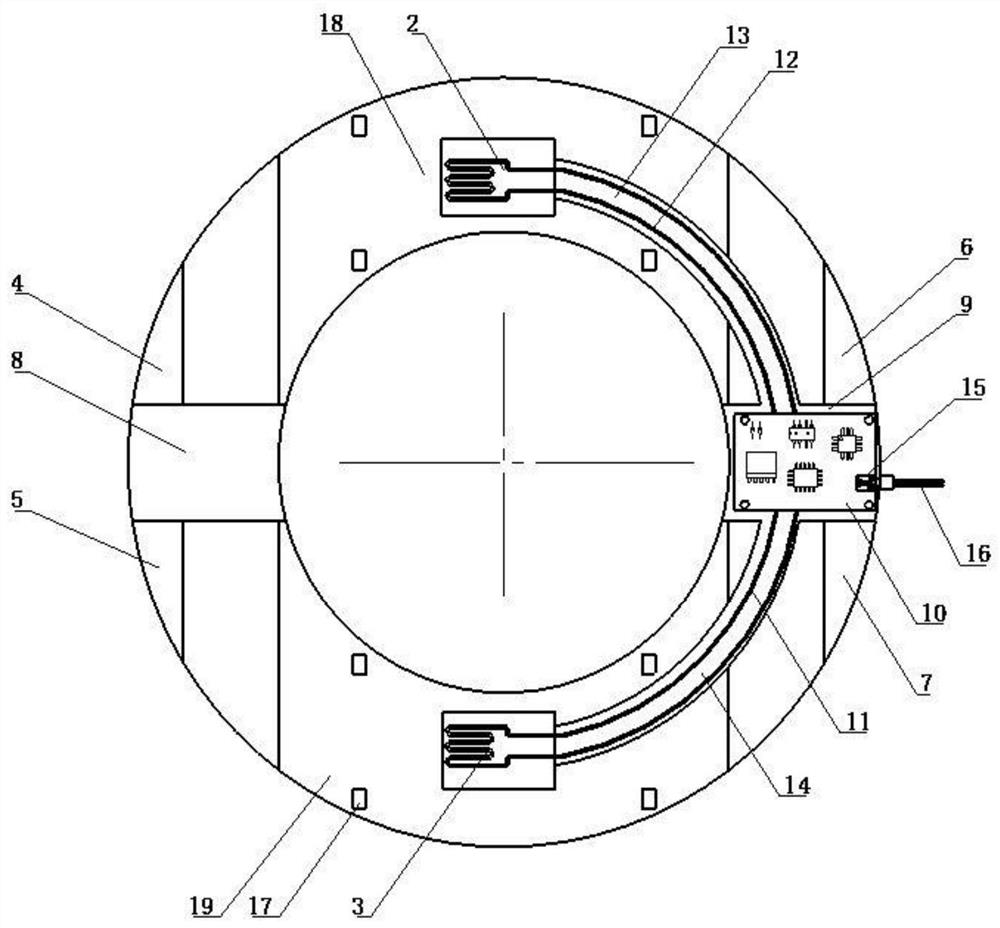

[0027] see Figure 1-5 The present invention provides a technical solution, a sensor-type elastic washer that can dynamically monitor the pretightening force of the threaded connection, including a washer main body 1, a strain gauge 2, a strain gauge 3 and an integrated circuit board 10. The shape of the elastic washer main body is similar to a saddle Saddle-shaped, the main body structure of the gasket is provided with four end planes 4, 5, 6, 7, two grooves 4 and 5, and two lead grooves 13 and 14, the saddle-shaped recess of the gasket main body Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com