Reinforced rat-proof threaded steel tube bow-type drop cable

A technology of threaded steel pipes and leading optical cables, which is applied in the direction of light guides, optics, optical components, etc., can solve problems such as poor compression resistance, increased manpower and material costs, and inability to apply long-span laying conditions, so as to improve tensile and compressive properties , Improve the effect of anti-rat bite performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

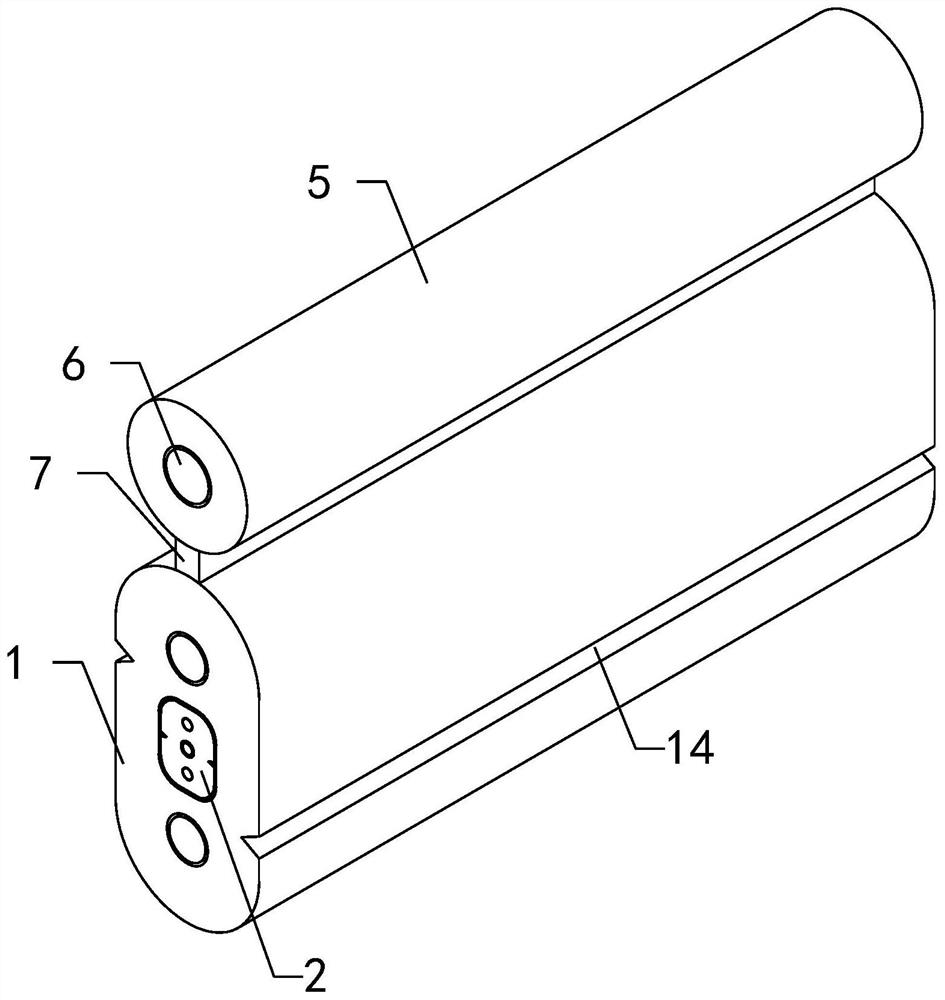

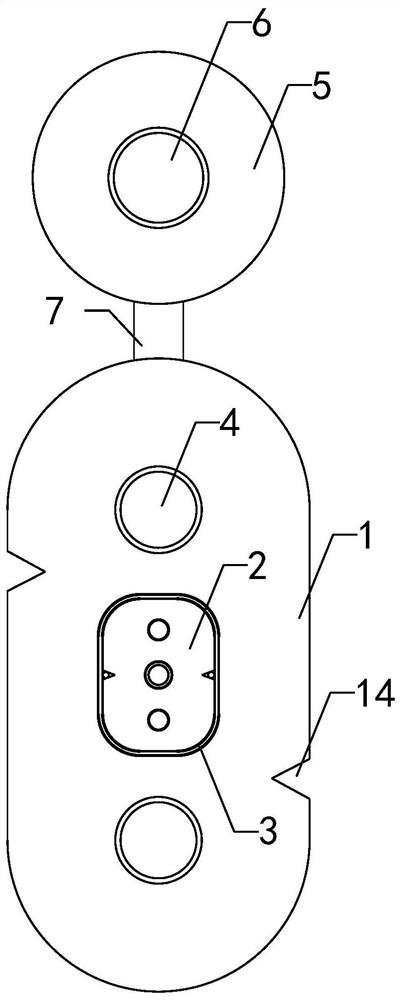

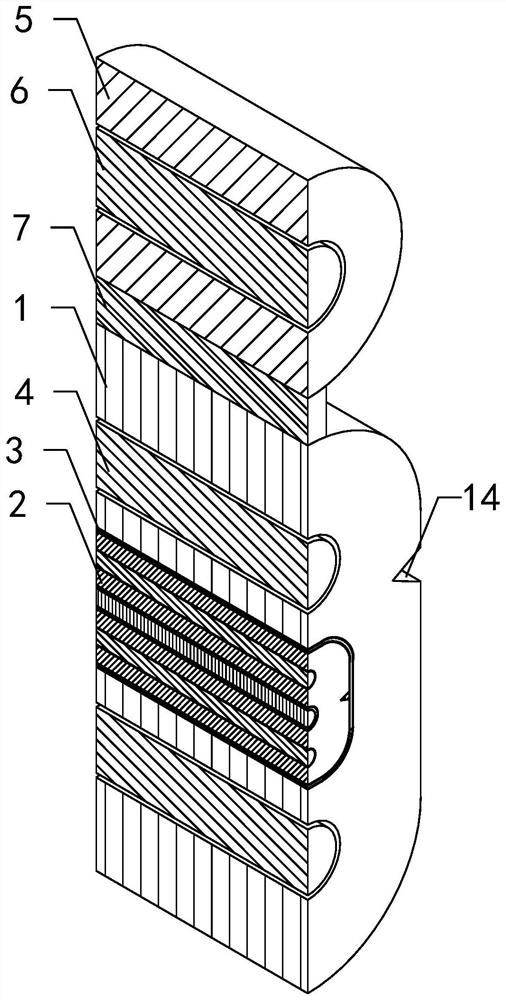

[0023] Embodiment 1, a reinforced rat-proof threaded steel pipe butterfly drop optical cable of the present invention includes a first outer sheath 1, an optical cable sub-unit 2, a glass fiber ribbon 3, a second outer sheath 5, and a second reinforcing member 6. and connector 7, the glass fiber ribbon 3 is sleeved on the outer wall of the optical cable sub-unit 2 by the tight sleeve process, the first outer sheath 1 is sleeved on the circumferential outer wall of the glass fiber ribbon 3 by the tight sleeve process, and the first outer sheath Two sets of first strength members 4 are arranged inside the sleeve 1 to improve the tensile performance of the optical cable. The unit 2 is axially symmetric, the second outer sheath 5 is sleeved on the circumferential outer wall of the second reinforcing member 6 through the tightening process, and the second outer sheath 5 is fixedly connected with the outer wall of the first outer sheath 1 through the connecting member 7. The axis of...

Embodiment 2

[0024] Embodiment 2, a reinforced rodent-proof threaded steel pipe butterfly drop optical cable, comprising a first outer sheath 1, an optical cable subunit 2, a glass fiber ribbon 3, a second outer sheath 5, a second reinforcing member 6 and a connector 7. The glass fiber ribbon 3 is sleeved on the outer wall of the optical cable sub-unit 2 through the tight sleeve process, and the first outer sheath 1 is sleeved on the peripheral outer wall of the glass fiber ribbon 3 through the tight sleeve process. The inside of the first outer sheath 1 Two sets of first strength members 4 are provided for improving the tensile performance of the optical cable, the axes of the two sets of first strength members 4 are parallel to the axis of the optical cable sub-unit 2, and the two sets of first strength members 4 are about the axis of the optical cable sub-unit 2. Symmetrical, the second outer sheath 5 is sleeved on the circumferential outer wall of the second reinforcing member 6 through...

Embodiment 3

[0025] Embodiment 3, a reinforced rat-proof threaded steel pipe butterfly drop optical cable, including a first outer sheath 1, an optical cable sub-unit 2, a glass fiber ribbon 3, a second outer sheath 5, a second reinforcing member 6 and a connector 7. The glass fiber ribbon 3 is sleeved on the outer wall of the optical cable sub-unit 2 through the tight sleeve process, and the first outer sheath 1 is sleeved on the peripheral outer wall of the glass fiber ribbon 3 through the tight sleeve process. The inside of the first outer sheath 1 Two sets of first strength members 4 are provided for improving the tensile performance of the optical cable, the axes of the two sets of first strength members 4 are parallel to the axis of the optical cable sub-unit 2, and the two sets of first strength members 4 are about the axis of the optical cable sub-unit 2. Symmetrical, the second outer sheath 5 is sleeved on the circumferential outer wall of the second reinforcing member 6 through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com