Wire pipe penetrating device for building transformation

A technology of threading device and wire tube, which is applied in the direction of cable installation device, cable installation, electrical components, etc., to achieve the effect of reducing influence and enhancing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

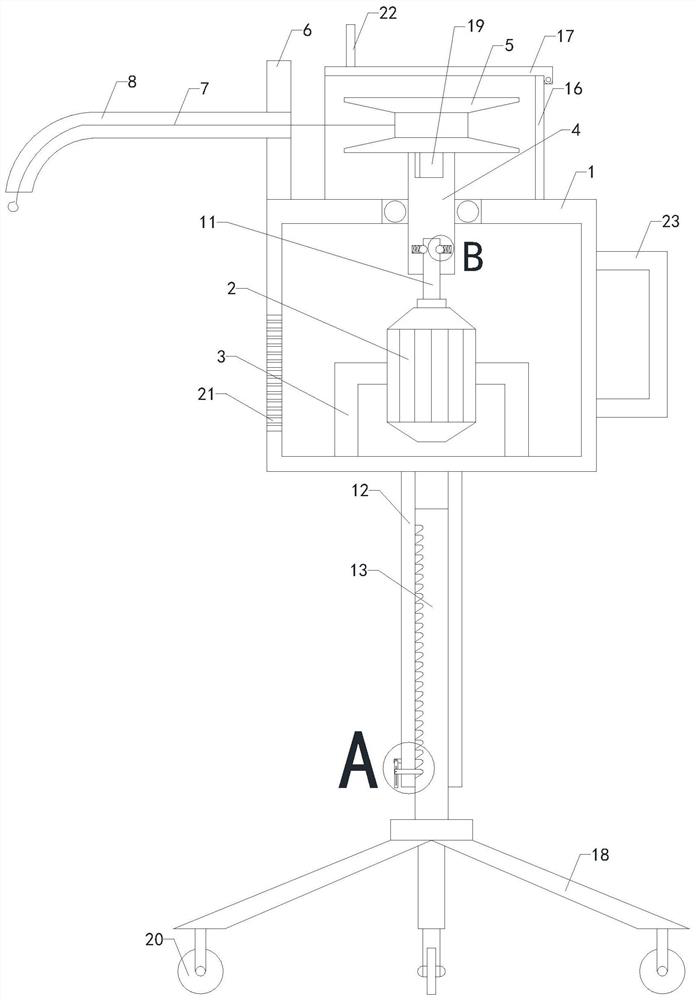

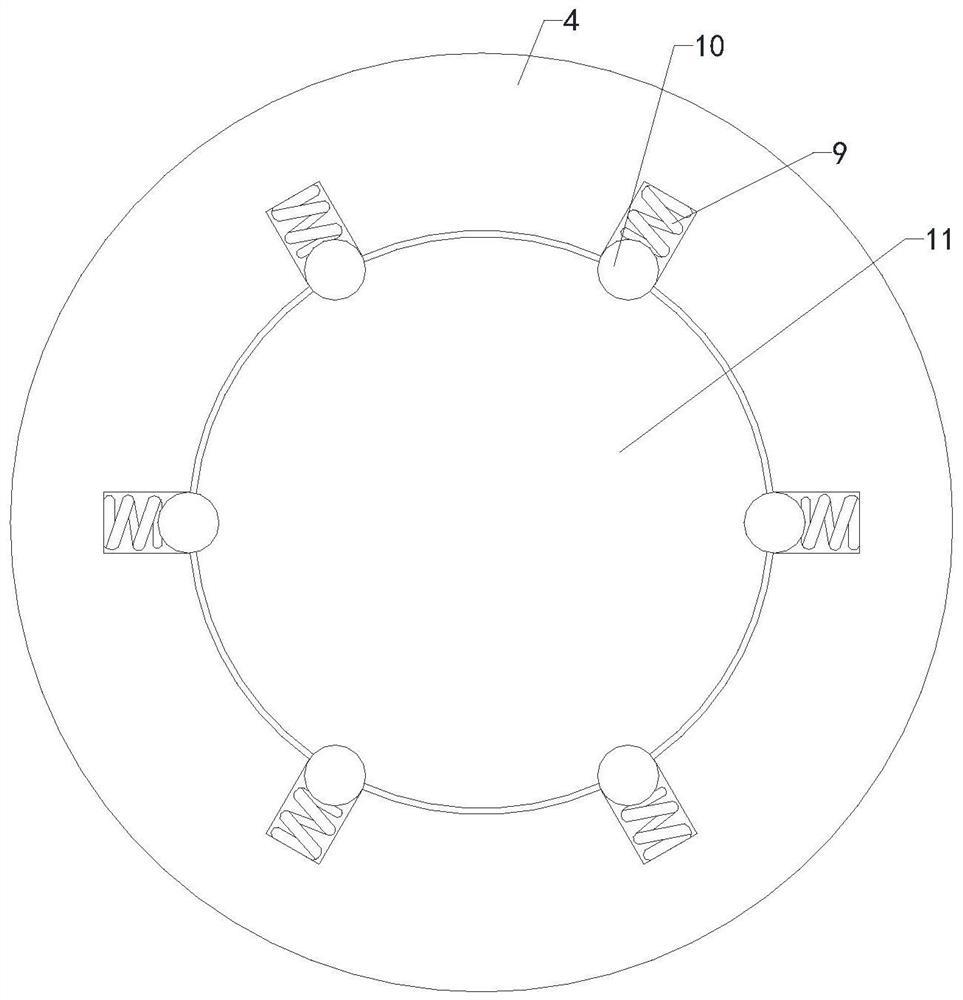

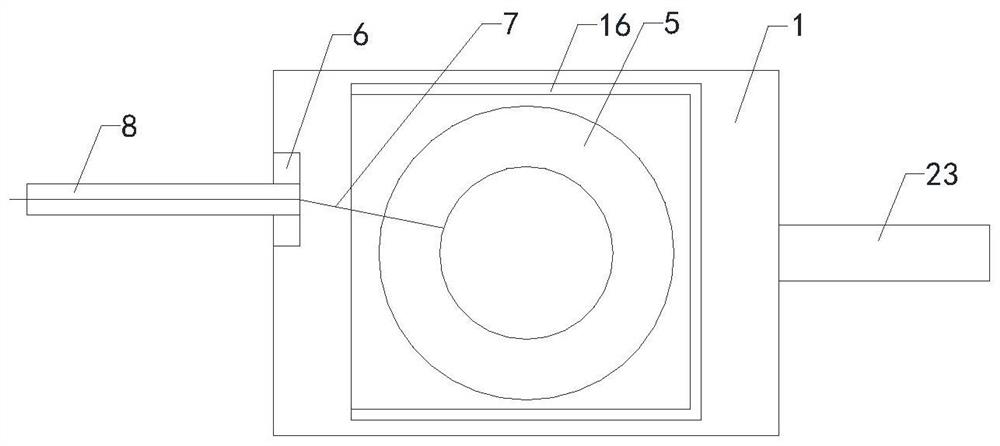

[0021] like Figure 1 to Figure 5 As shown, a wire pipe threading device for building reconstruction of the present invention includes a cabinet 1, a motor 2, a bracket 3, a rotating shaft 4, a wiring shaft 5, a fixing plate 6, a line pipe 8, connecting wires 7, and multiple groups of springs 9 and multiple sets of spherical blocks 10, a working chamber is arranged in the cabinet 1, the motor 2 is installed in the middle area of the bottom end of the working chamber through the bracket 3, the output end of the motor 2 is provided with a transmission shaft 11, and the top of the rotating shaft 4 extends out of the working chamber The top is also connected to the chassis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com