A carbon neutralization system and method for sponge-type composite gutters of highways

A technology of carbon neutrality and side ditch, applied in chemical instruments and methods, water treatment of special compounds, treatment of polluted waterways/lakes/ponds/rivers, etc., can solve problems such as shortage, reduce carbon emissions, increase carbon Sink effect, effect of increasing planting area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

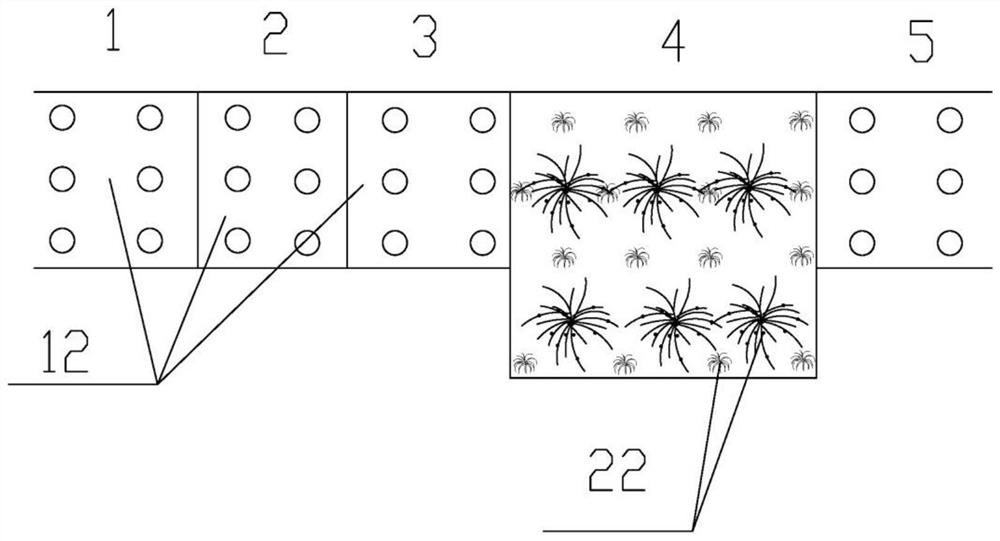

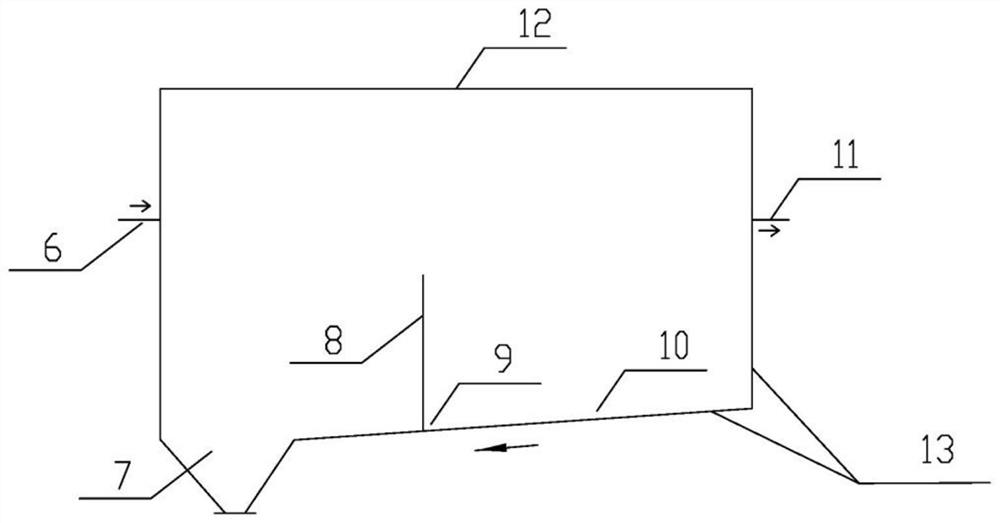

[0100] A sponge-type composite side ditch carbon neutral system for roads, which is composed of a sediment pre-sedimentation ditch, a filter oil suction ditch and an ecological purification ditch connected in sequence. The front and rear of the sponge-type composite side ditch carbon neutralization system are ordinary side ditch, which are set at intervals. The bottom and side walls of the sponge-type composite side ditch carbon neutralization system are paved with two anti-seepage geotextiles and one membrane.

[0101] The upstream longitudinal pavement runoff collected by the inlet ditch flows in through the middle and upper part of the inlet side of the sediment pre-sedimentation channel of the first water inlet. The water flows out from the first water outlet in the middle and upper part of the outlet side of the pre-settling channel, and enters from the middle and upper part of the inlet side of the filter oil absorption channel. The side bottom flows out through the sec...

Embodiment 2

[0107] A sponge-type composite side ditch carbon neutralization system is implemented in a two-way four-lane expressway. The design length of the catchment unit is 100m, and the length of the unit sponge-type composite side ditch is 45m. 5m, and the unit ecological purification canal is 32m long.

[0108] The unit sediment pre-sedimentation channel is 1.5m deep, 1m wide, and has a volume of 12m 3 . The unit filter oil suction channel is 1.5m deep, 1m wide, and has a volume of 7.5m 3 . The unit ecological purification channel is 1.5m deep, 2m wide, with an aspect ratio of 16:1 and a volume of 96m 3 .

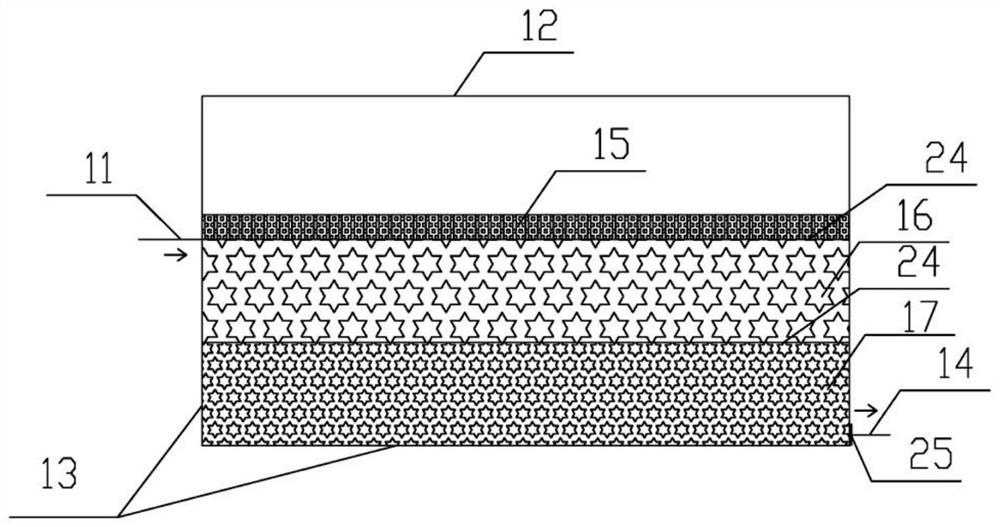

[0109] Considering that raw materials such as polyester sponge and polyether sponge around the expressway are transported far away, in order to reduce engineering costs and carbon emissions during the construction stage, the filter oil suction channel is laid from bottom to top with zeolite with a particle size of 50 cm and a particle size of 20 mm and a particle size of 50 c...

experiment example 1

[0121] The highway sponge type composite side ditch carbon neutralization system is as in Example 1. Samples were taken at the water inlet ditch, the sediment pre-sedimentation ditch, the outlet of the filter oil suction ditch, the outlet of the filter oil suction ditch, and the outlet of the ecological purification ditch. The contents of pollutants TN, TP, COD, and SS in water samples at different locations, among which total nitrogen (TN) was measured by potassium persulfate digestion-ultraviolet spectrophotometry, and total phosphorus (TP) was measured by phenol-hypochlorite spectrophotometry method, chemical oxygen demand (COD) was determined by potassium dichromate method, and suspended solids (SS) were determined by oven-dried gravimetric method. The test results are as described in Table 2.

[0122] Table 2 Purification effect of sponge-type composite side ditch carbon neutral system (mg / L)

[0123] Sampling point TN TP COD SS Ditch 5.4 0.2 53 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com