Yarn-dyed fabric edge yarn warping method

A technology of yarn-dyed fabric and side yarn, which is applied in the field of yarn warping, can solve the problems of inability to achieve on-demand production, different quality requirements of raw materials, and inability to distinguish side yarn from cloth body, etc., so as to reduce the use of normal raw yarn, The effect of reducing the amount of dyeing and reducing the amount of yarn waste generated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

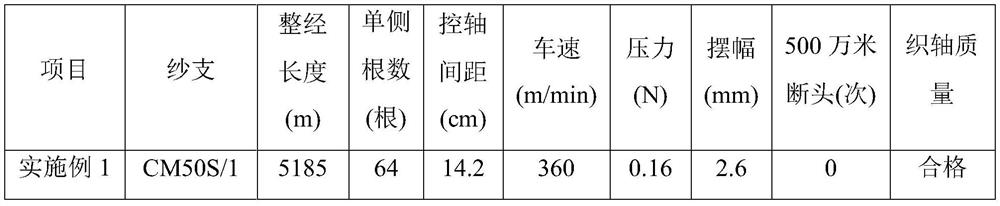

Embodiment 1

[0027] Adopt the yarn-dyed side yarn warping method of the present invention, wherein the warping machine adopts a batch warping machine, and the warping machine is equipped with 2 sets of static elimination devices, which are opened during warping, the warp beam is a stainless steel warp beam, and the warp yarn paper tube is The pipe head is made of seamless paper tube, and 2 distance control discs are added inside the warp beam. The distance control disc is 14.2cm away from the warp beam fixed disc. The yarn count is CM50S / 1. root.

[0028] Warping steps are as follows:

[0029] (1) Spin defective yarns or secondary recycled yarns into tight warp yarns at a speed of 800m / min, the original yarn and tight warp yarns share a vertical center line, and the distance between the two is 95cm;

[0030] (2) Carry out warping production in sequence, and the tight warp yarn density is 400g / dm 3 , the yarn is soft and moderate, the unwinding is normal, and the creel is parallel to the ...

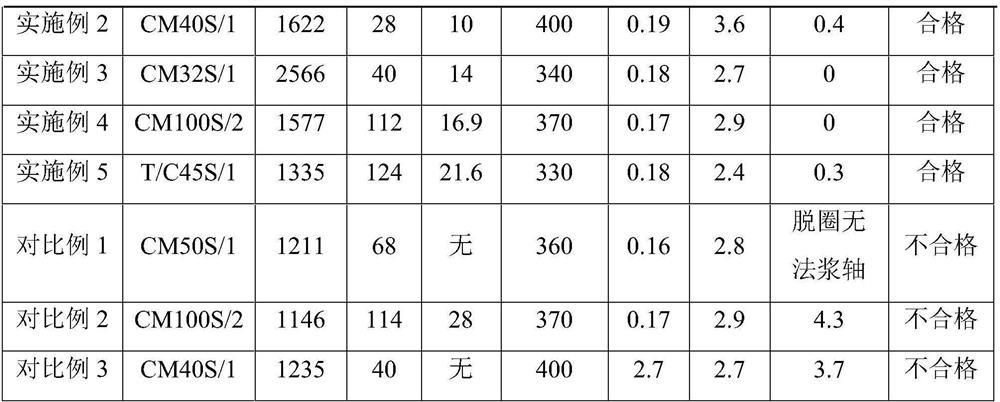

Embodiment 2

[0035] Adopt the yarn-dyed fabric side yarn warping method of the present invention, wherein the warping machine adopts a batch warping machine, and the warping machine is equipped with 2 sets of static elimination devices, which are opened during warping, the warp beam is a stainless steel warp beam, and the warp paper tube It is a seamless paper tube at the pipe head, and 2 distance control discs are added inside the warp beam. The distance control discs are 10cm away from the warp beam fixed disc, the yarn count is CM40S / 1, the warping length is 1622m, and the number of warping threads on one side is 28 root.

[0036] Warping steps are as follows:

[0037] (1) Spin defective yarns or secondary recycled yarns into tight warp yarns at a speed of 950m / min, the original yarn and tight warp yarns share a vertical center line, and the distance between the two is 92cm;

[0038] (2) Carry out warping production in sequence, and the tight warp yarn density is 400g / dm 3 , the yarn ...

Embodiment 3

[0043] Adopt the yarn-dyed fabric side yarn warping method of the present invention, wherein the warping machine adopts a batch warping machine, and the warping machine is equipped with 2 sets of static elimination devices, which are opened during warping, the warp beam is a stainless steel warp beam, and the warp paper tube It is a seamless paper tube at the tube head, and 2 distance control discs are added inside the warp beam. The distance control disc is 14cm away from the warp beam fixed disc, the yarn count is CM32S / 1, the warping length is 2566m, and the number of warp warps on one side is 40 root.

[0044] Warping steps are as follows:

[0045] (1) Spin defective yarns or secondary recycled yarns into tight warp yarns at a speed of 950m / min, the original yarn and tight warp yarns share a vertical center line, and the distance between the two is 94cm;

[0046] (2) Carry out warping production in sequence, and the tight warp yarn density is 420g / dm 3 , the yarn is soft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com