Plastic high and cold atmospheric environment-tensile load coupling acceleration test method

A technology of accelerated testing and load coupling, applied in the field of environmental testing, can solve problems such as inability to reflect, achieve significant acceleration, and meet the effect of rapid assessment and evaluation

Pending Publication Date: 2021-08-24

NO 59 RES INST OF CHINA ORDNANCE IND

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Aiming at the deficiencies in the above-mentioned prior art, the present invention proposes a plastic alpine atmospheric environment-tensile load coupling accelerated test method, which truly reflects the degradation effect of aging and tensile load coupling in the alpine atmospheric environment on the performance of

Method used

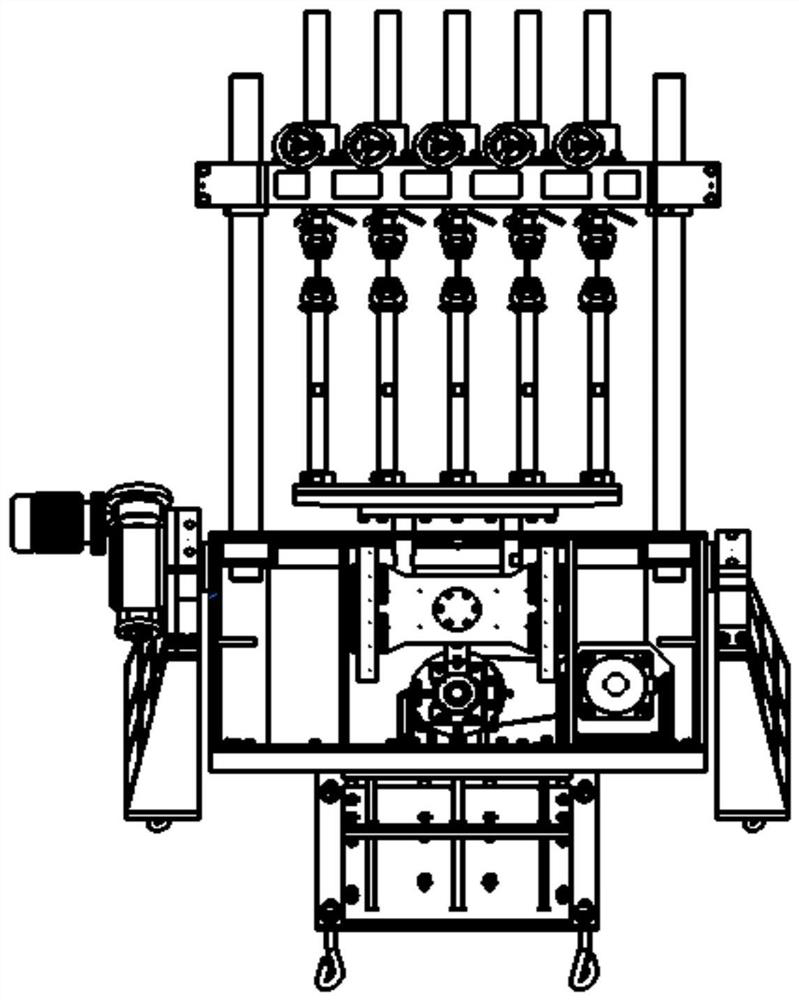

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

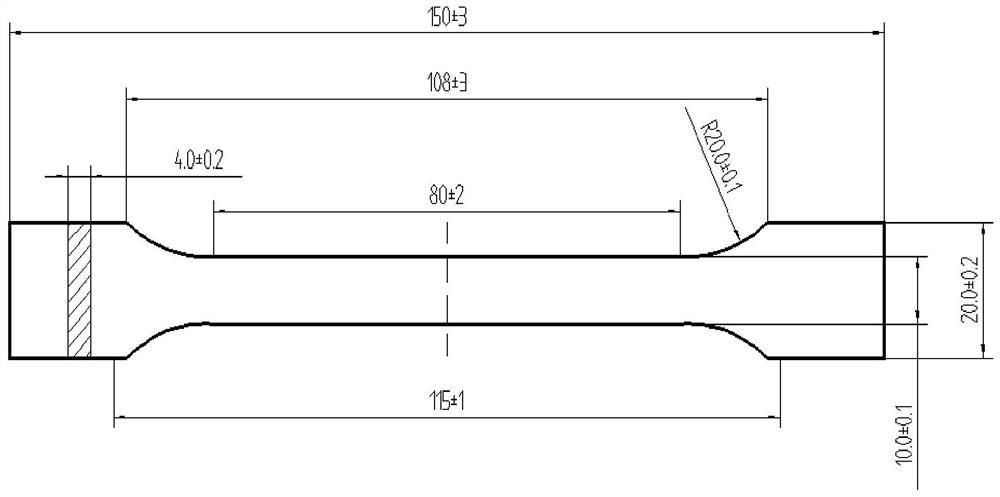

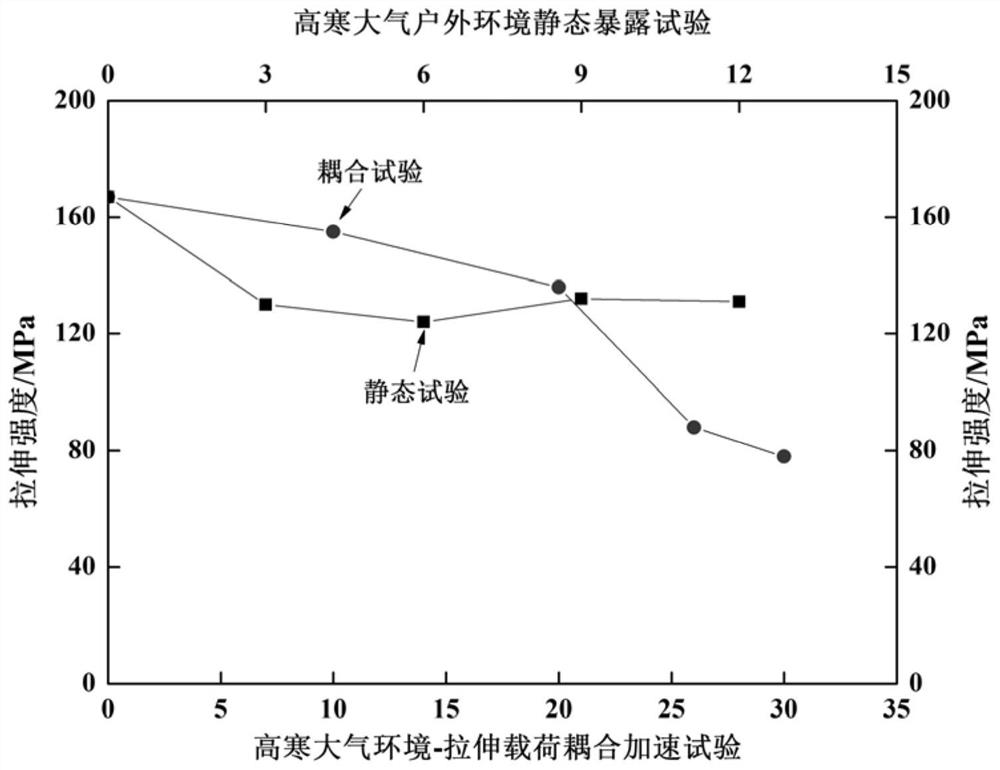

The invention discloses a plastic high and cold atmospheric environment-tensile load coupling acceleration test method. The method adopts tensile strength as an evaluation index and takes a high and cold atmospheric outdoor environment static exposure test result as a reference to contrastively analyze the acceleration of the the load coupling acceleration test method in three aspects, namely, alternating circulation tests of a static tensile load loading test, a dynamic tensile fatigue loading test and a static exposure test in the alpine atmosphere outdoor environment in the alpine atmosphere outdoor environment, the dynamic tensile fatigue loading test in the high and cold atmosphere outdoor environment and the static tensile load loading test in the high and cold atmosphere outdoor environment relative to the static exposure test in the high and cold atmosphere outdoor environment. The degradation influence of the coupling effect of aging and tensile load on the plastic performance in the high and cold atmosphere environment is truly reflected, and the defects that a traditional laboratory acceleration test is difficult to truly reflect the comprehensive influence of aging of various environmental factors of the high and cold atmosphere, and a natural environment static exposure test cannot reflect the influence of the tensile load are overcome.

Description

technical field [0001] The invention relates to the technical field of environmental testing, in particular to a plastic alpine atmospheric environment-tensile load coupled accelerated testing method. Background technique [0002] With the continuous improvement of equipment / product lightweight development requirements, plastics are widely used in equipment / product development and production due to their high specific strength, light weight, excellent mechanical properties, easy processing, and low cost. A large number of advanced plastics are used in the load-bearing parts of equipment / products, and "replacing steel with plastic" has become an increasingly common phenomenon. [0003] As a load-bearing part, plastics may encounter more complex working conditions during the entire life cycle of equipment / products, especially in extremely harsh environments such as alpine atmospheric environments, where they are not only subjected to aging due to various atmospheric environmen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/18G01N3/32G01N17/00

CPCG01N3/18G01N3/32G01N17/00G01N2203/0003G01N2203/0005G01N2203/0017G01N2203/0073G01N2203/0228

Inventor 罗来正张宸冯利军吴帅杨小奎吴洋王晓辉王健坤刘溅洪袁艺李超

Owner NO 59 RES INST OF CHINA ORDNANCE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com