Device and method for producing material sheet

A material board and equipment technology, applied in the direction of manufacturing tools, metal sawing equipment, metal processing equipment, etc., can solve problems such as increased power demand, achieve good acceleration value, cheap price, and improve economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

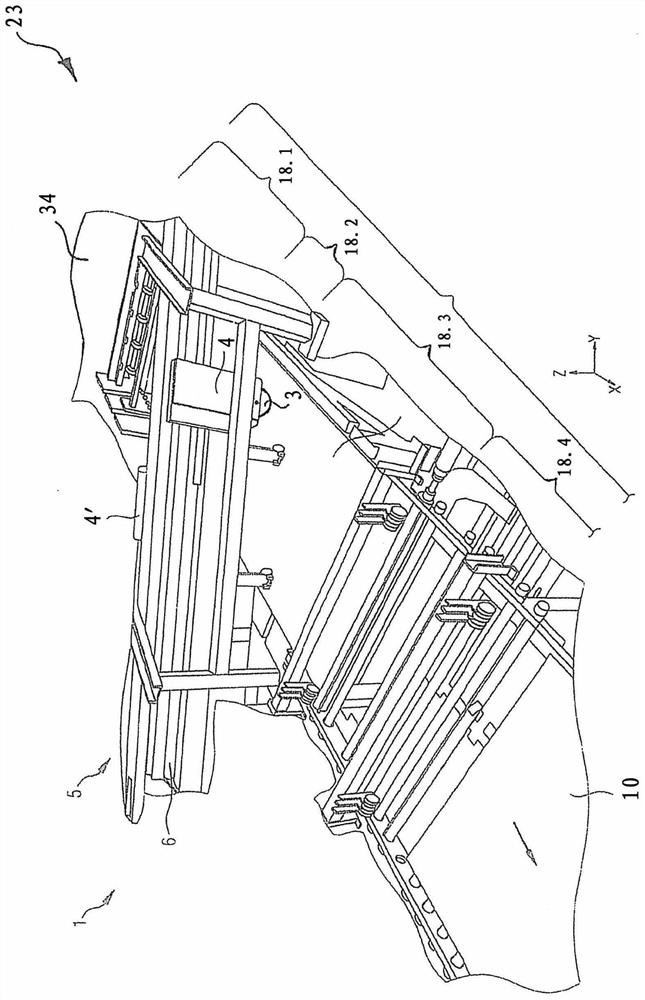

[0048] figure 1 A section of a panel production plant 23 , as known from the prior art, is shown in a perspective view with a device 1 for producing a panel 10 connected thereto.

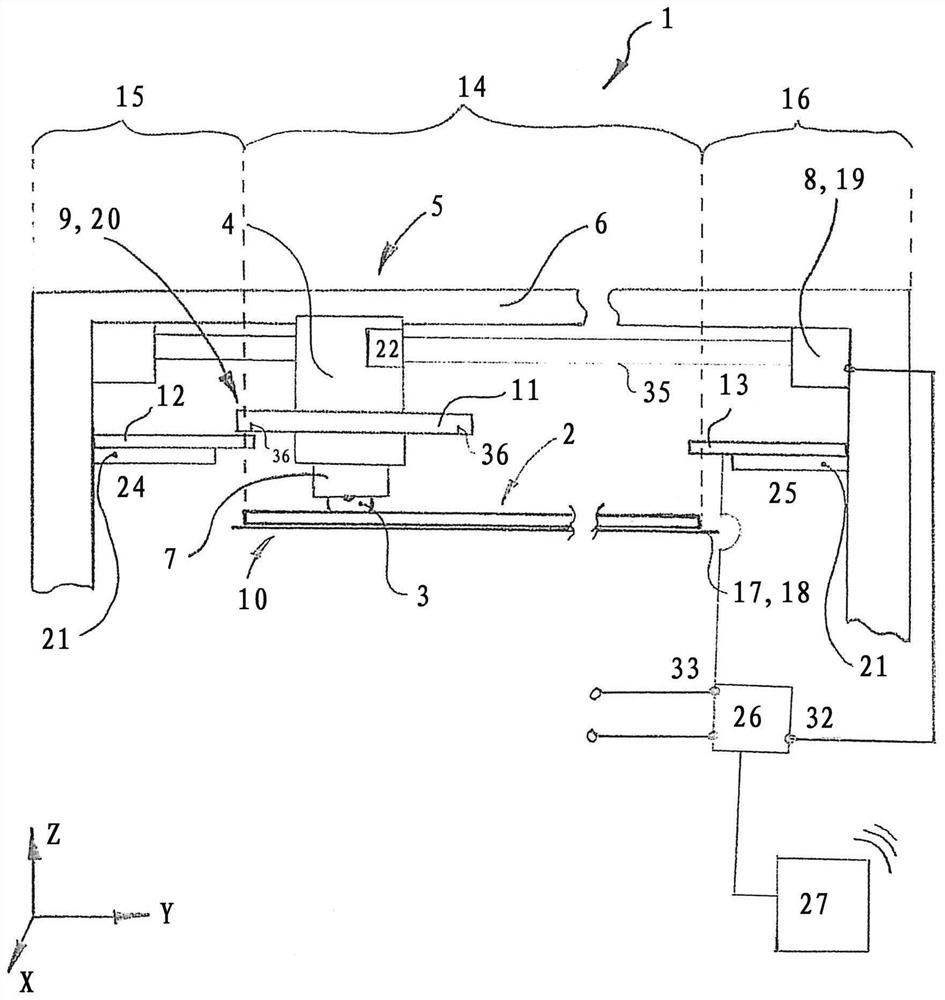

[0049] The material plate production apparatus 23 is arranged in space such that its longitudinal direction is along the X axis, its transverse direction (width) is along the Y axis, and its height direction is formed along the Z axis. The section shown corresponds to at least one part of a system for transporting and in particular for separating and dividing a material sheet 10 which emerges as a continuous web 2 from a production plant 34 which in particular has a continuously operating pressure machine, such as the applicant's A press, here also can comprise a machine for producing a material sheet 10, in particular for dividing a web 2 extending in three spatial directions X, Y, Z and having limited dimensions in at least two spatial directions Y, Z The device, said device 1 comprising at lea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com