Muddy water open-type dual-mode shield tunneling machine provided with normal-pressure cutterhead

An open shield machine technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of inability to meet safe and efficient construction requirements, limited application range of shield machines, high construction costs, etc., and achieve Efficient tunnel forming work, saving engineering construction costs, and preventing surface collapse or uplift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described with reference to the accompanying drawings.

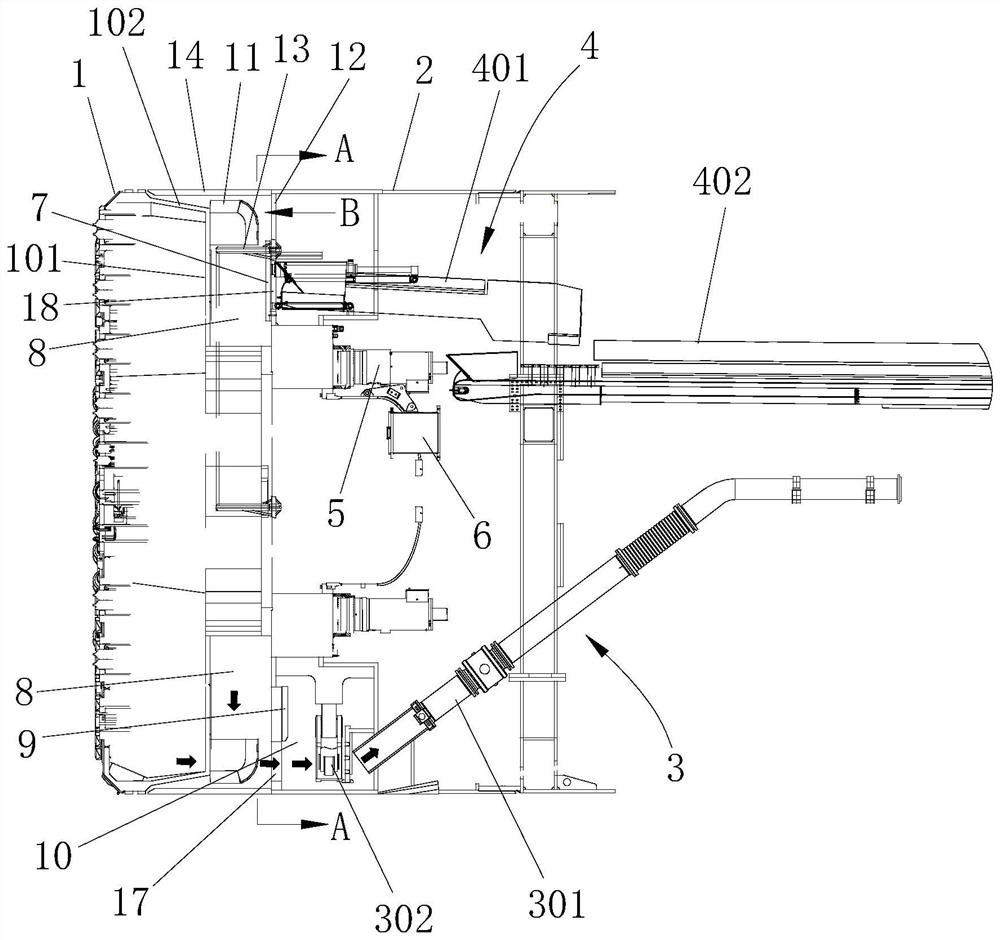

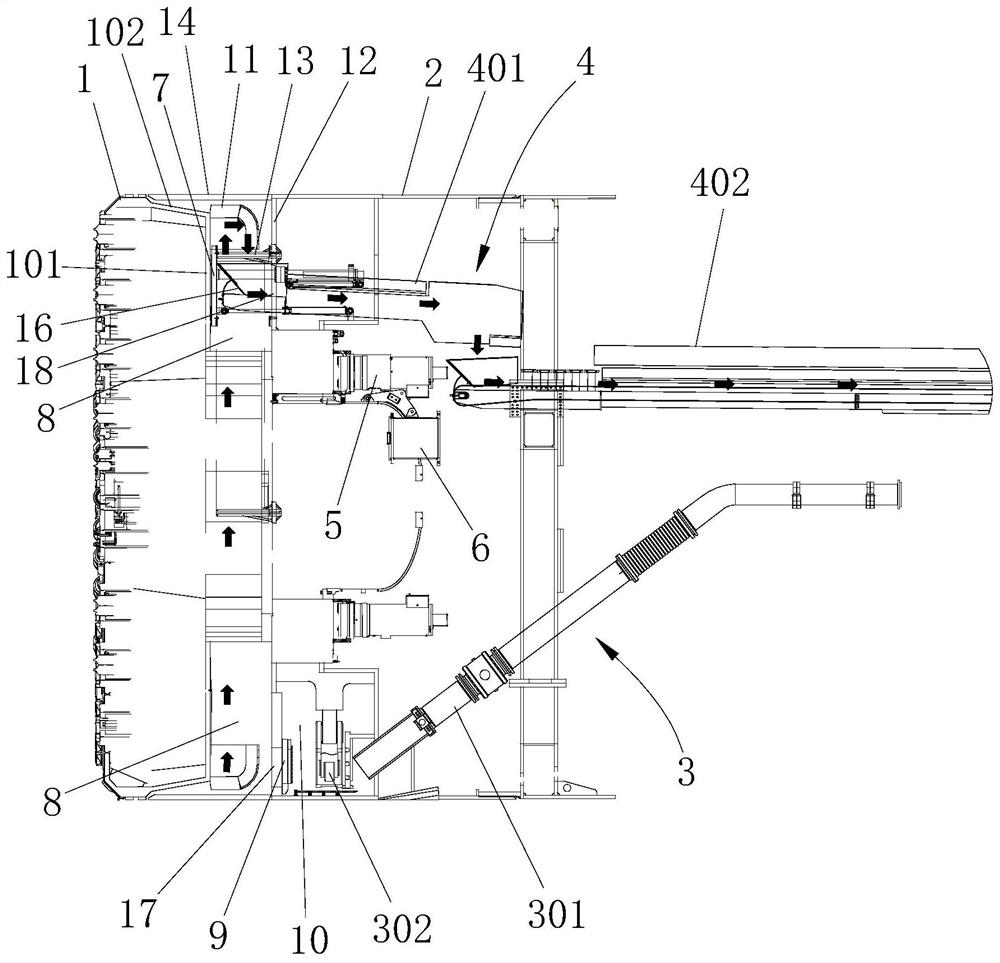

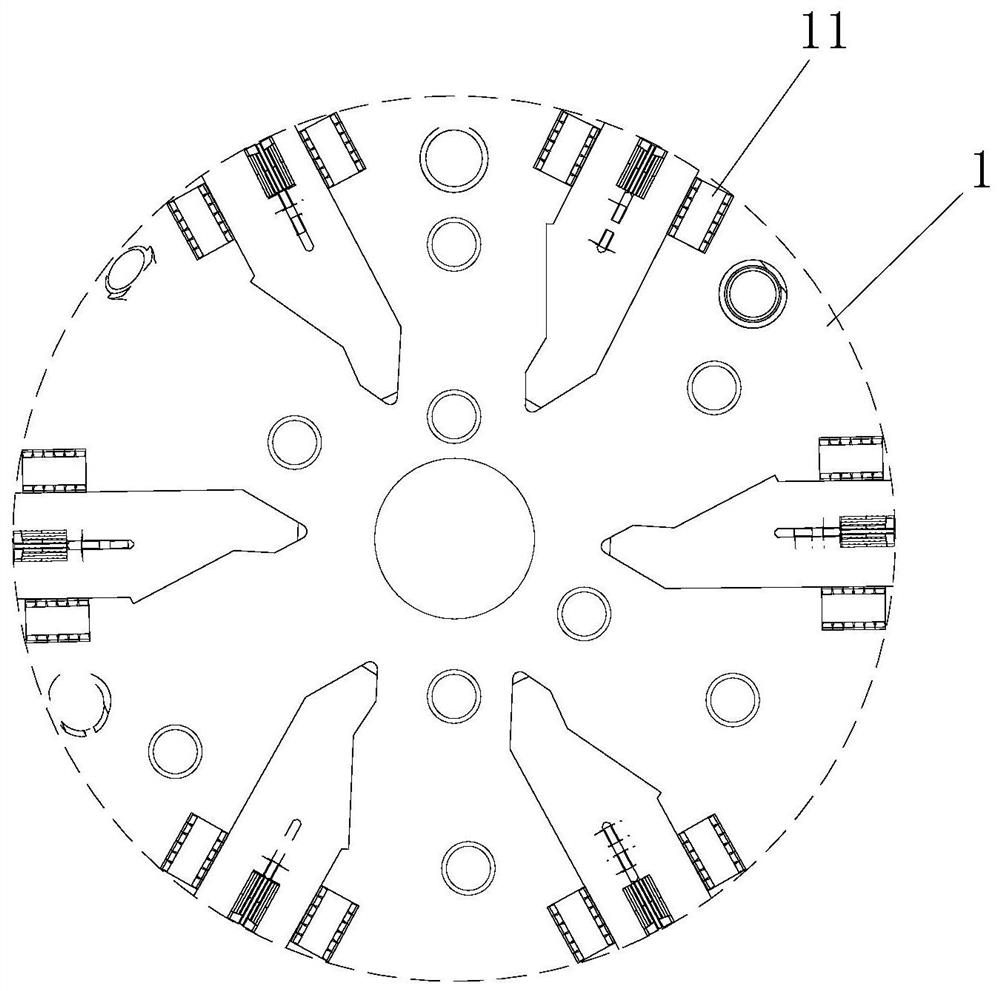

[0044] like Figure 1 to Figure 5As shown, the present invention provides a muddy water open double-mode shield machine equipped with an atmospheric cutterhead, comprising a shield body 2, an atmospheric cutterhead 1, a first slag discharge device 3 and a second slag discharge device 4, usually The pressure cutter head 1 is arranged on the front part of the shield body 2, and a muck chamber 8 is formed between the atmospheric pressure cutter head 1 and the shield body 2, and the first slag discharge device 3 and the second slag discharge device 4 are fixedly arranged on the shield body Inside of body 2. The bottom of the slag cabin 8 is provided with a mud delivery port 17 that communicates with the slag cabin 8, and the top of the slag cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com