Screening machine of mining equipment

A technology for mining equipment and screening machines, which is applied to mechanical equipment, screens, solid separation, etc., and can solve problems such as the inability to adjust the slope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

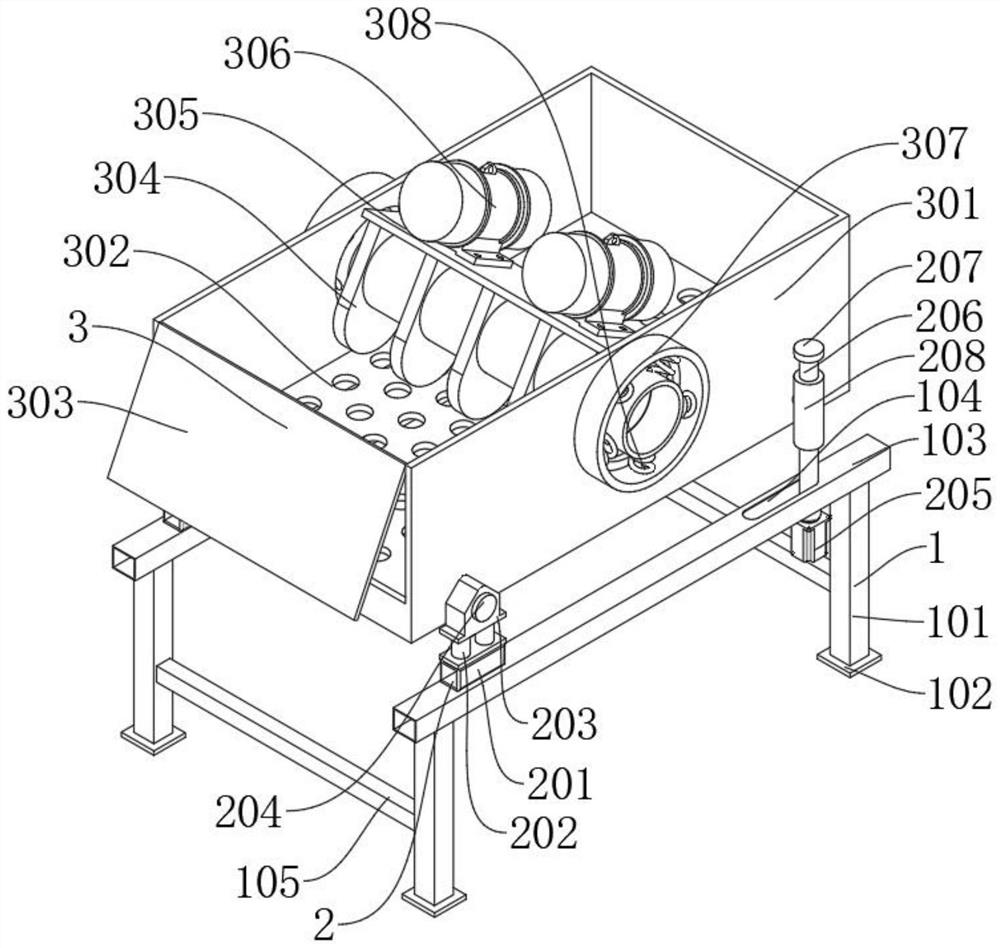

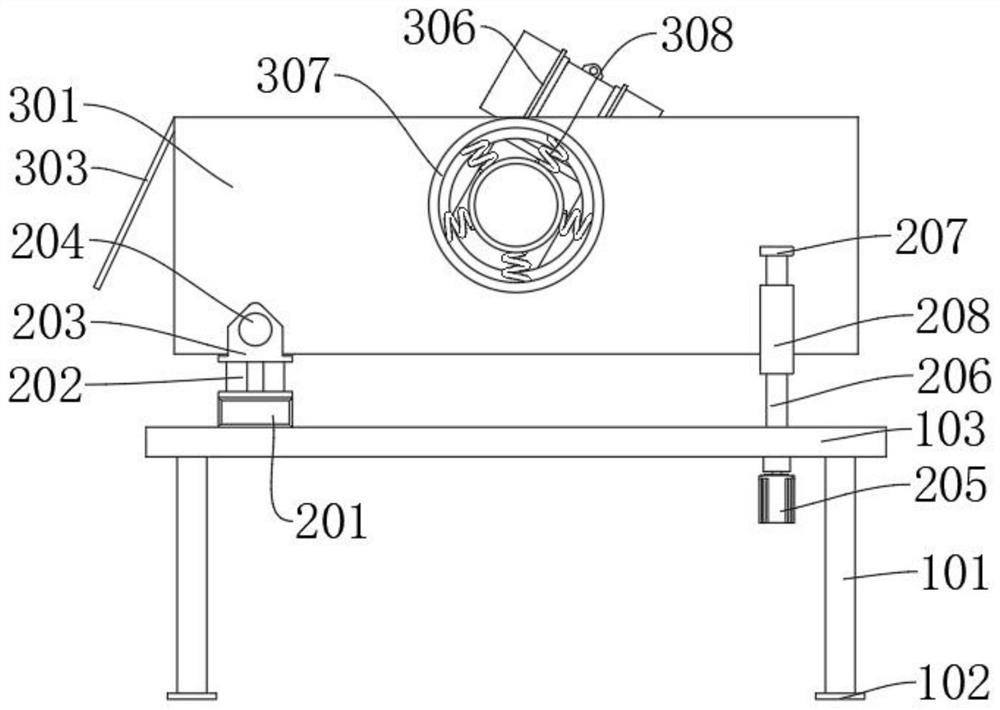

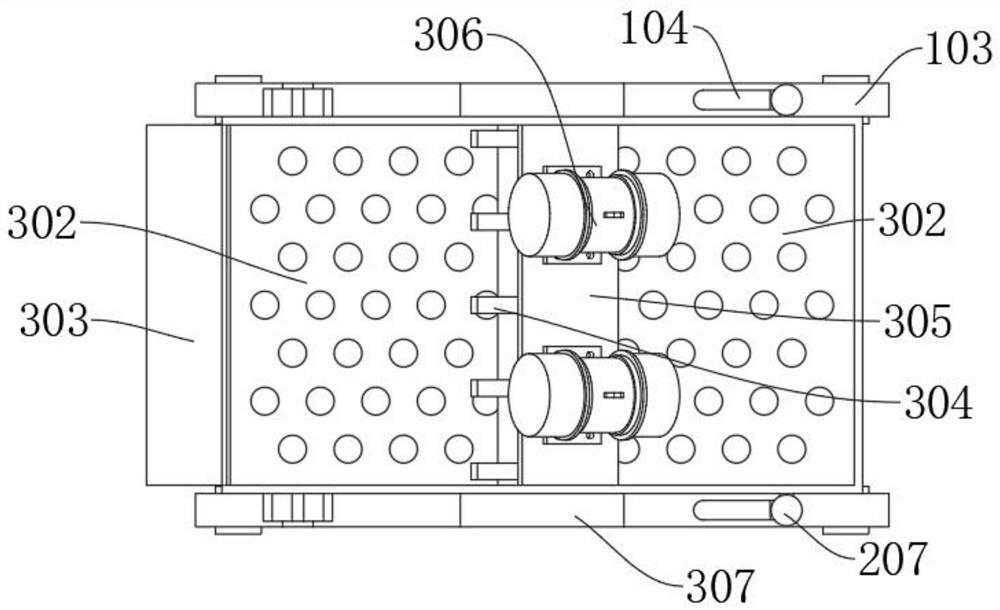

[0026] see Figure 1-Figure 4 , the present invention provides a mining equipment screening machine: including a supporting mechanism 1, an adjusting mechanism 2, the upper part of the supporting mechanism 1 is provided with an adjusting mechanism 2, and also includes a screening mechanism 3 for vibration screening of ore blocks, the screening mechanism 3 It includes a screening box 301, a screening plate 302, a rotating door 303, a vibration shaft 304, a bearing plate 305, a vibration motor 306, a bearing ring 307, and a stabilizing spring 308. The screening box 301 is installed between the adjustment mechanisms 2, and the internal In the screening area, one side of the screening box 301 is rotatably connected with a revolving door 303, which can be rotated to take out the sieved ore, and a screening plate 302 is installed on the inner bottom of the screening box 301, which can remove smaller ore Screened out, the vibrating shaft 304 is installed in the middle section of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com