An embedded power controller

A power controller, embedded technology, applied in the direction of electrical components, electrical equipment casing/cabinet/drawer, casing/cabinet/drawer components, etc., can solve the collision of surrounding objects, power controller damage, unconsidered to the power controller block and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

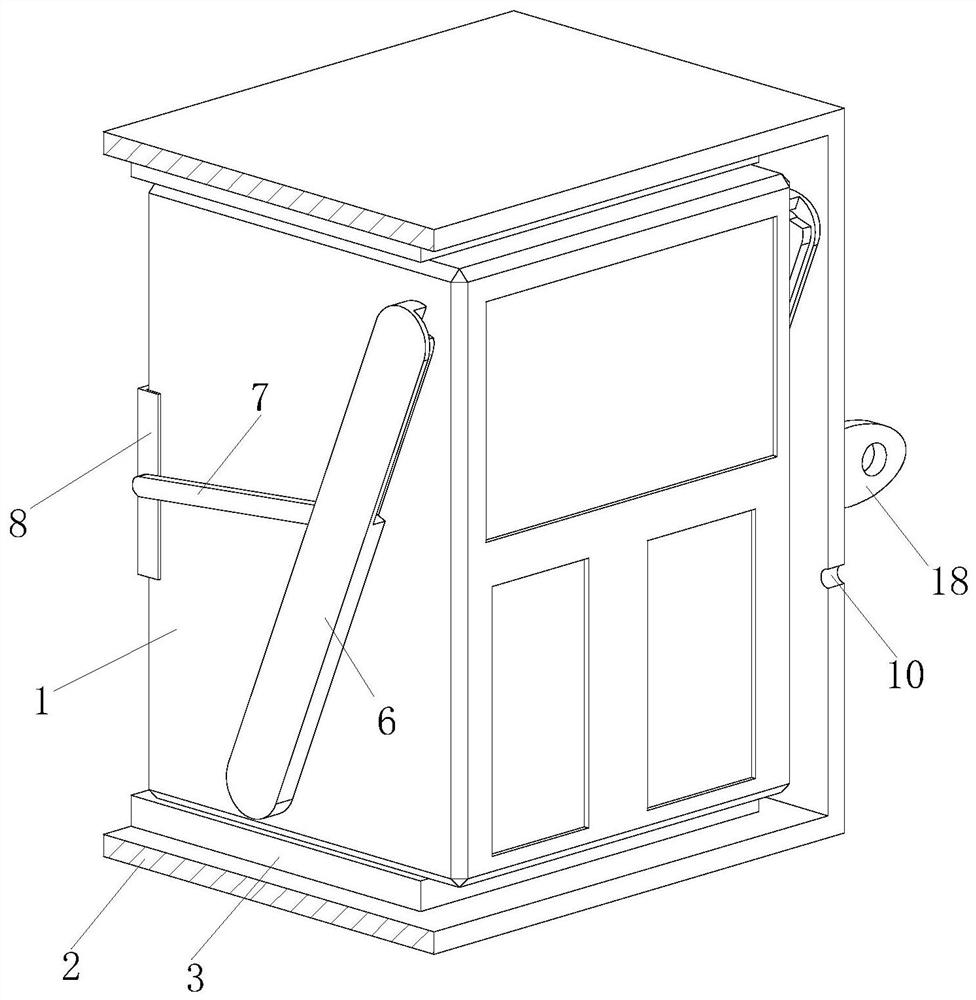

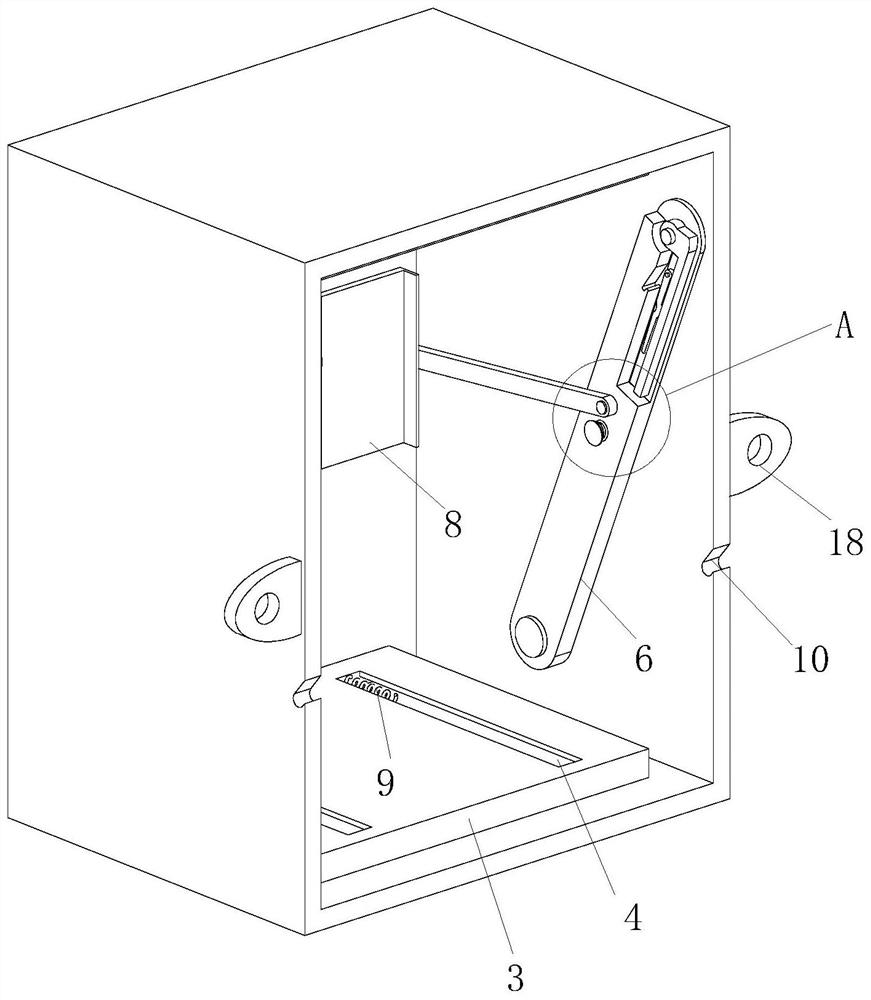

[0029] refer to Figure 1-7 , an embedded power supply controller, including a power supply controller body 1, the power supply controller body 1 is installed in a groove reserved on the wall through a box body 2; the box body 2 is provided with a substrate 3 and a pull Structure; the number of the base plate 3 is two, the upper and lower sides of the base plate 3 are respectively fixed on the inner top surface and the inner bottom surface of the box body 2, the base plate 3 is provided with a T-shaped groove 4, and the T-shaped groove 4 is slidably connected with a connection Block 5, the connection block 5 is fixedly connected to the upper top surface and the lower bottom surface of the power supply controller body 1;

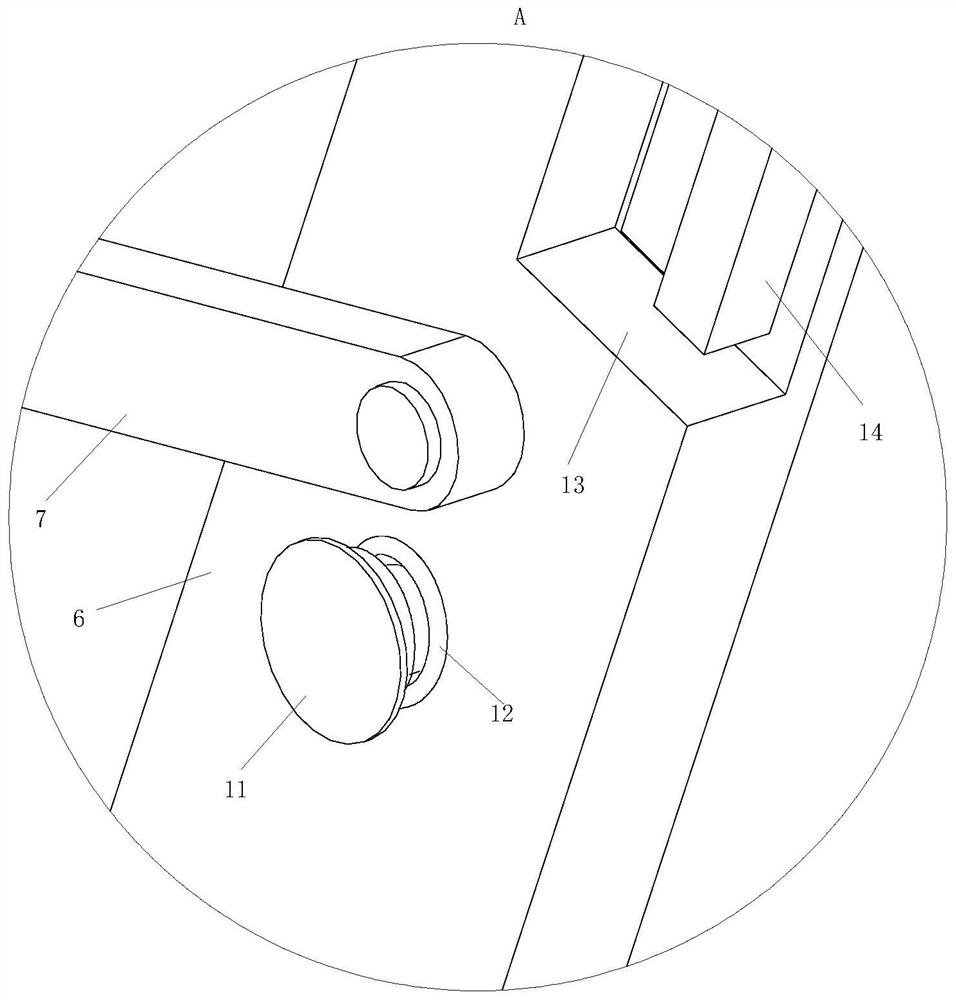

[0030] The two sides of the power controller body 1 are provided with a pulling structure No. 1 rod 6, No. 2 rod 7 and an L-shaped plate 8; The middle area of 6 is rotated to connect one end of the second pole 7, and the other end of the second pole 7 is r...

Embodiment 2

[0039] refer to Figure 8 , Comparative Example 1, as another embodiment of the present invention, wherein the inner side wall of the placement groove 16 is provided with a magnetic block 19, the magnetic block 19 adsorbs the support rod 17 in the placement groove 16, and then rotates the pull rod 14 to the concave portion 13. When inside, the support rod 17 needs to be rotated into the placement slot 16 first. By adsorbing the support rod 17 in the placement slot 16 , the support rod 17 is prevented from drooping vertically by itself, which affects the retraction of the pull rod 14 .

[0040] Working principle: Push the box body 2 into the groove, the outer port of the box body 2 is lower than the notch of the groove, some foam glue can be applied to the inner surface of the groove, the volume of the foam glue gradually increases, and the box body 2 is squeezed in the groove. In the groove, the power controller body 1 is assembled into the box body 2, so as to protect the pow...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap