Double-nut constraint type lock bolt structure

An anti-loosening bolt and double-nut technology, applied in the direction of nuts, bolts, screws, etc., can solve problems such as the threat of safe operation of the line and the easy loosening of the anti-loosening performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

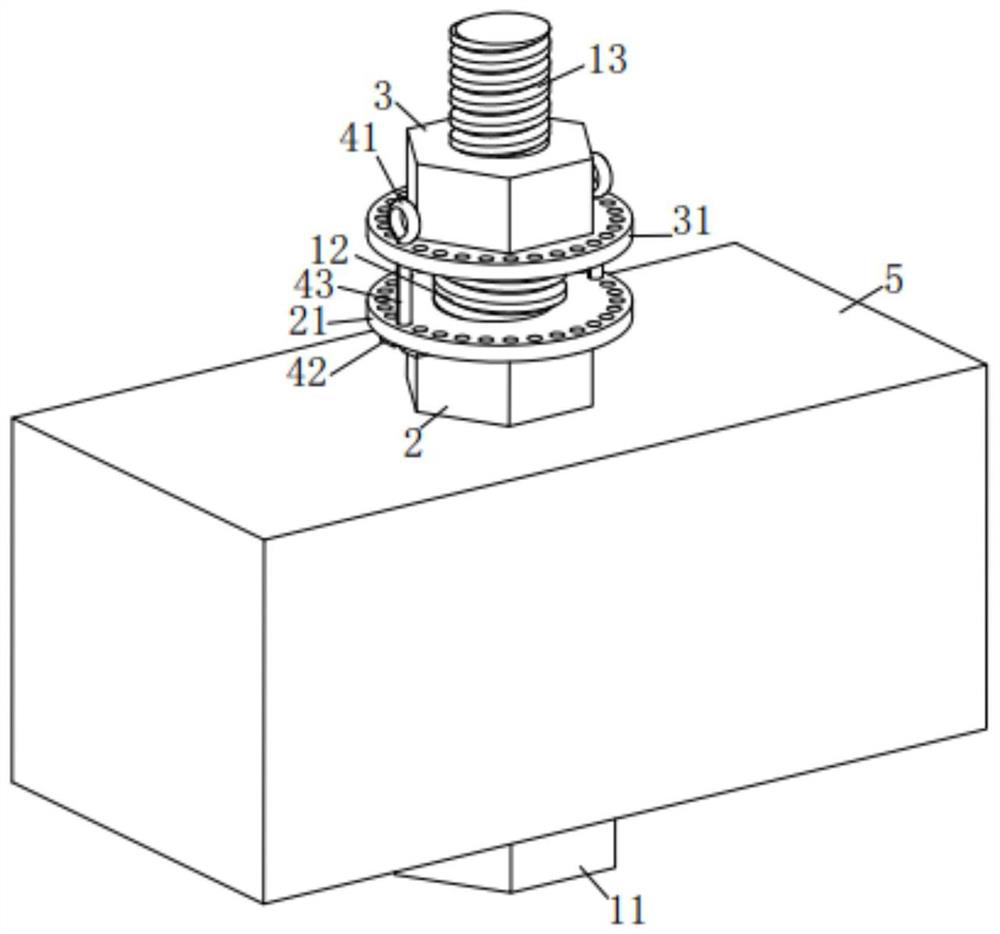

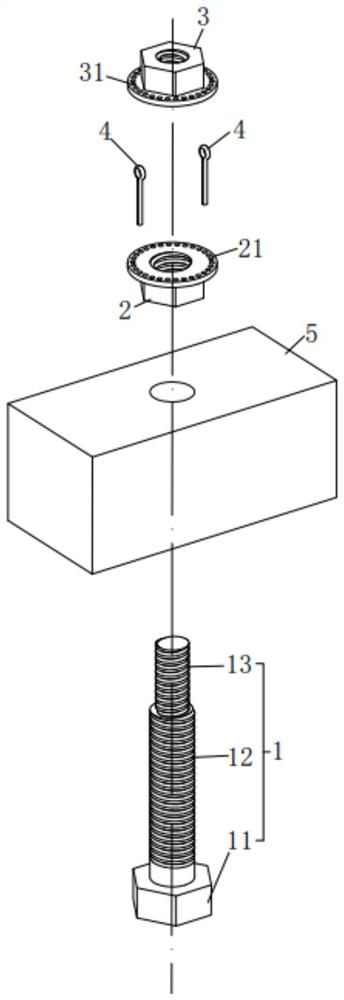

[0029] The present invention proposes a double-nut constrained anti-loosening bolt structure, such as figure 1 As shown, it includes a bolt 1, a main nut 2, a secondary nut 3 and a limit pin 4. The bolt 1 is composed of a bolt head 11, a first screw 12 and a second screw 13 fixedly connected in sequence, and the diameter of the first screw 12 is larger than that of the second screw. Two screw rods 13, the thread of the first screw rod 12 is opposite to the direction of rotation of the thread of the second screw rod 13, the main nut 2 is threaded with the first screw rod 12, the secondary nut 3 is threaded with the second screw rod 13, and the main nut 2 is provided with The main flange 21 and the auxiliary nut 3 are provided with an auxiliary flange 31, the main flange 21 and the auxiliary flange 31 are provided with holes, the limit pin 4 can be deformed, and inserted into the main flange 21 and the opening of the auxiliary flange 31 are used to prevent the relative rotation ...

Embodiment 2

[0034] The present invention proposes a double-nut constrained anti-loosening bolt structure, which can also be set as follows: the limit pin 4 is set as a "匚" type structure, and the perforated section 43 is pierced through the main flange 21 and the auxiliary flange 31. In the hole, the positioning section 41 is arranged on the side of the auxiliary flange 31 facing away from the main flange 21 , and the anti-off section 42 is arranged on the side of the main flange 21 facing away from the auxiliary flange 31 .

Embodiment 3

[0036] The present invention proposes a double-nut constrained anti-loosening bolt structure, which can also be set as follows: the perforated section 43 is arranged on the outside of the main flange 21 and the auxiliary flange 31, and the positioning section 41 is pierced through the auxiliary flange 31 In the hole on the main flange 21 , the anti-off section 42 is passed through the hole on the main flange 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com