Vertical radiator automatic core assembling machine

A radiator, automatic technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing the assembly efficiency of the radiator core, unable to meet the processing requirements, and long working time of the radiator core.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The vertical radiator automatic core loading machine of the present invention will be described in detail below with reference to the accompanying drawings. It should be noted that components illustrated in the figures are not necessarily drawn to scale. The present invention omits descriptions of well-known components and well-known technologies in order to avoid unnecessarily limiting the present invention.

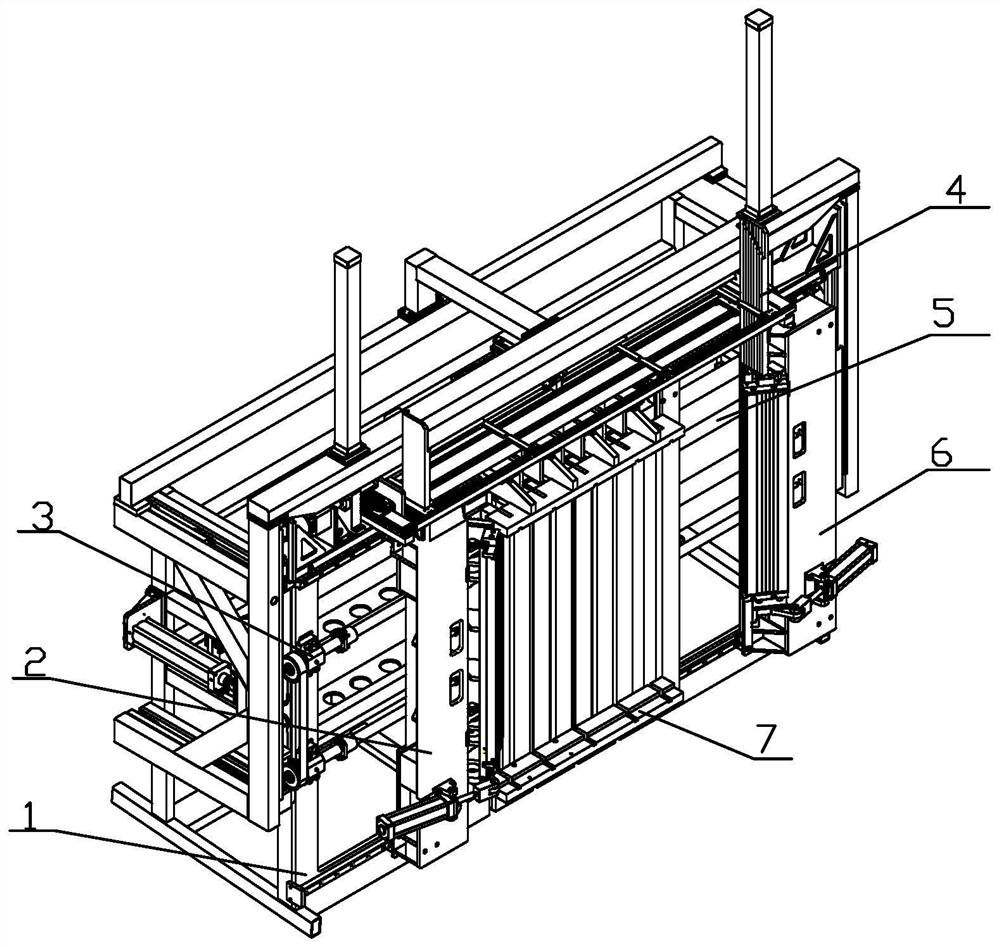

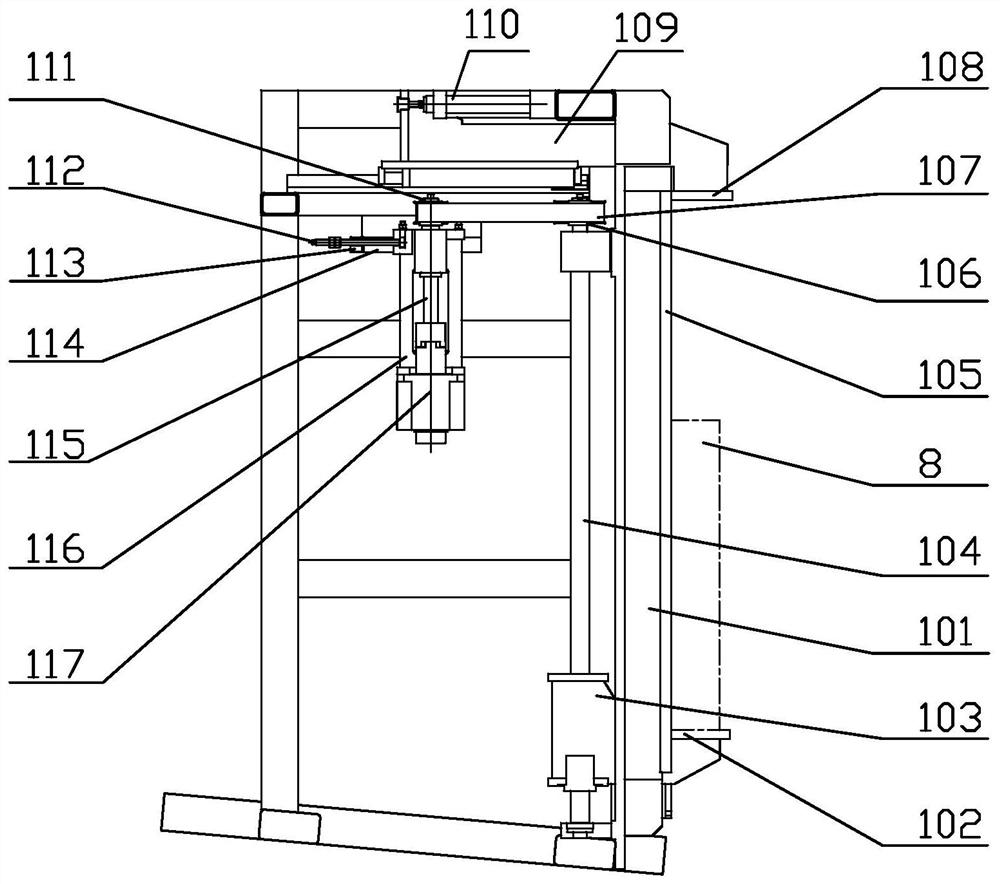

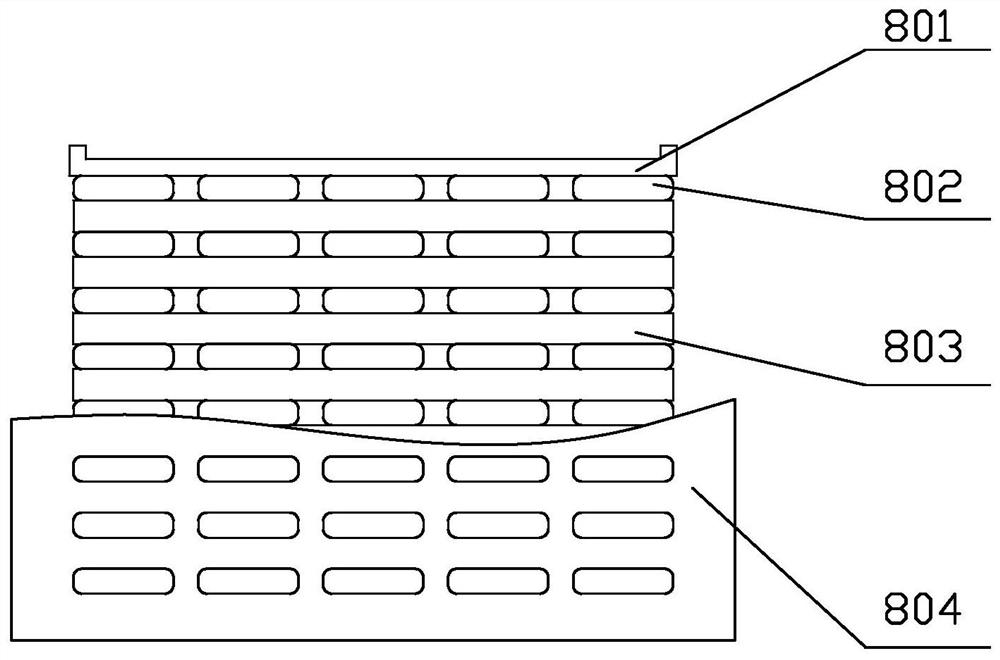

[0035] Such as Figure 1 to Figure 5As shown, the vertical radiator automatic core loading machine of the present invention has a structure comprising a frame mechanism 1, a main board pressing mechanism left 2, a servo driving mechanism left 3, a drop tube device 4, a servo driving mechanism right 5, and a main board pressing Mechanism right 6 and workbench 7, frame mechanism 1 is fixed on the ground, and described workbench 7 is arranged on the middle part of one side of frame mechanism 1, and described mainboard pressing mechanism left 2 and mainboard pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com