Vertical roller cardan shaft safety device and using method

A technology of safety device and cardan shaft, which is applied in the safety equipment of rolls, the driving device for metal rolling mills, metal rolling, etc., and can solve the problems of dangerous situations for operators, injuries of operators, low radian and dimensional accuracy, etc. , to achieve the effect of reducing the danger of working at heights, avoiding potential safety hazards and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

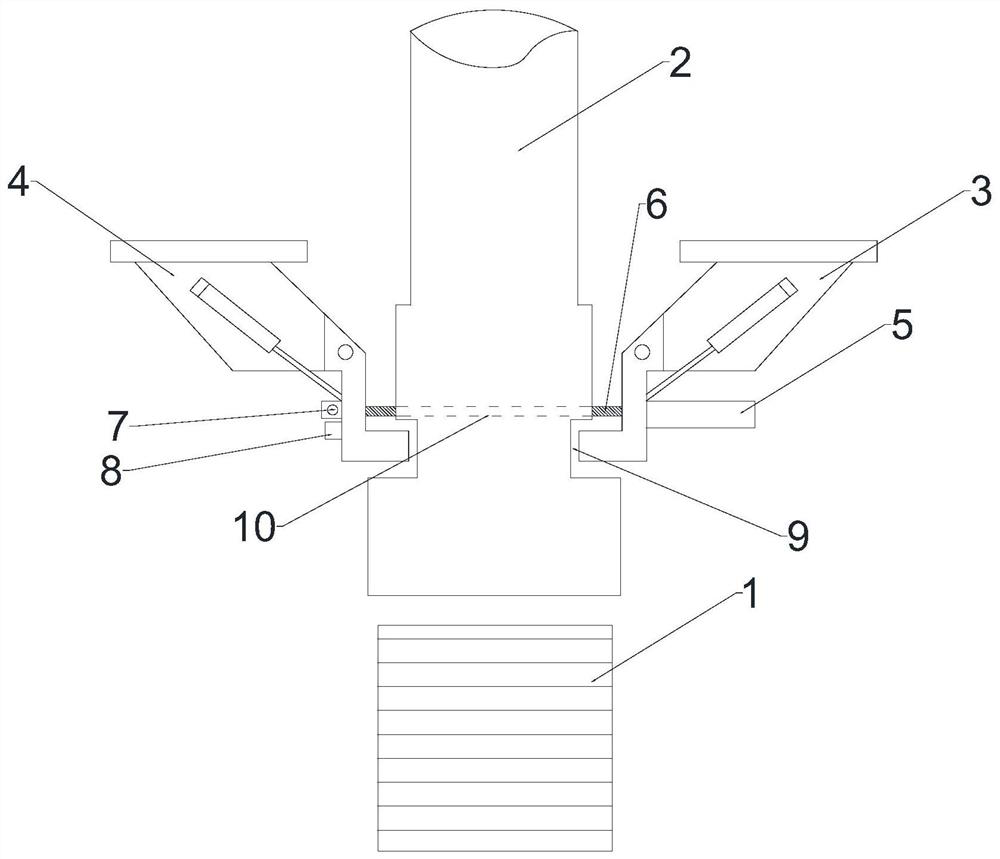

[0039] see figure 1, the present embodiment provides a vertical roll cardan shaft safety device, including a vertical roll 1, a cardan shaft 2, and a bracket system, the vertical roll 1 is connected and driven through the cardan shaft 2; the bracket The bracket system includes a bracket and a hydraulic cylinder, the bracket includes a first bracket 3 and a second bracket 4 symmetrically arranged on both sides of the cardan shaft, the first bracket 3 and the second bracket The frame 4 can be driven by the hydraulic cylinder to jointly support the cardan shaft 2; the first bracket is provided with an electric cylinder 5 and an electric cylinder telescopic rod 6, and the top end of the electric cylinder telescopic rod 6 is provided with a ring lock hole 7, the second bracket is provided with an opening (not shown in the figure), and an electric plug lock is provided at the opening; when replacing the roll, the vertical roll 1 and the universal The shaft 2 is separated, and when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com