Power takeoff rack test device and test method thereof

A technology of bench test and test method, which is applied in the field of transmission test, can solve the problem of not establishing a complete system for reliability test assessment and so on.

Active Publication Date: 2021-09-21

HARBIN DONGAN AUTO ENGINE

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] At present, some models of T18R transmissions have been equipped with power take-offs and occupy a certain amount of the market. Although the new models T1

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

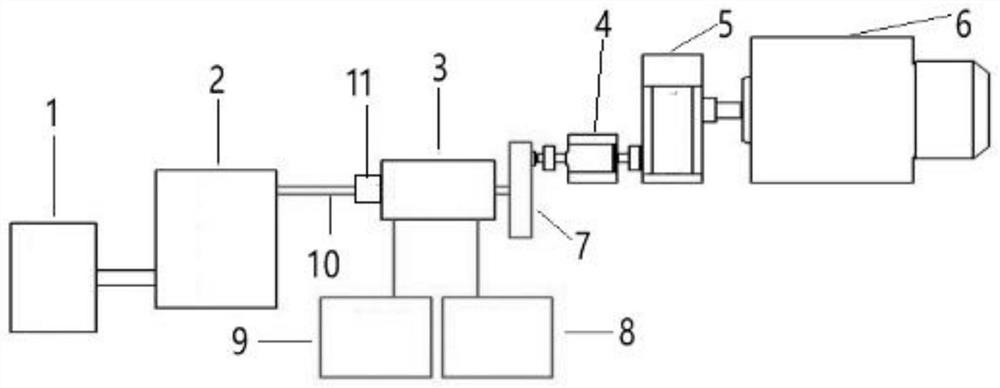

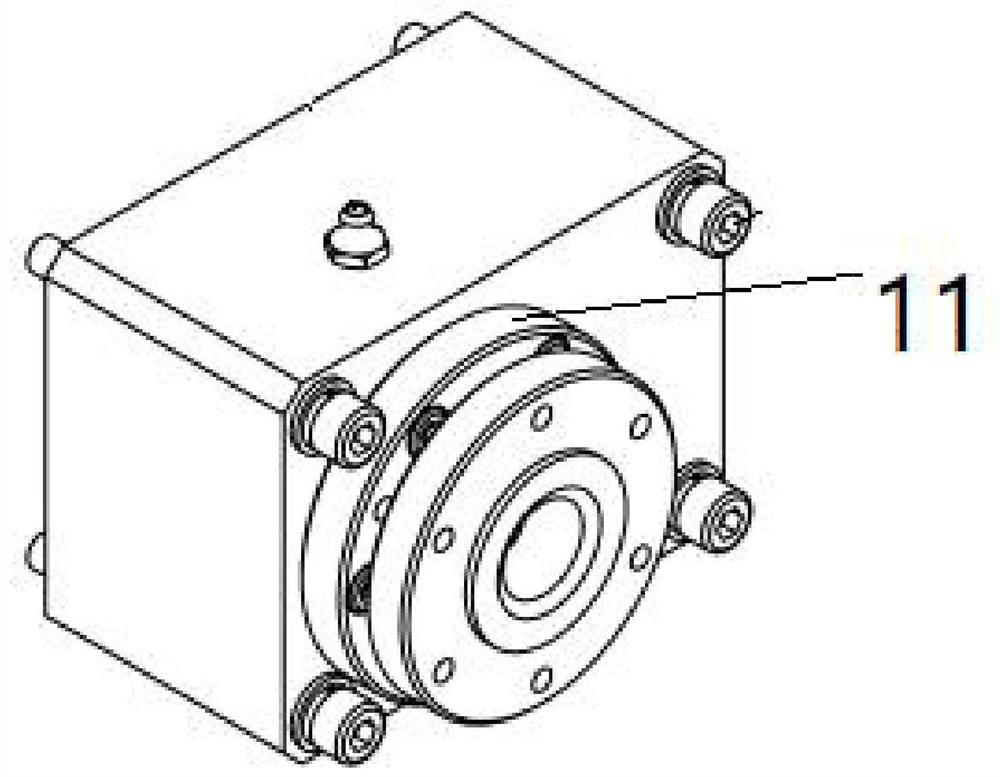

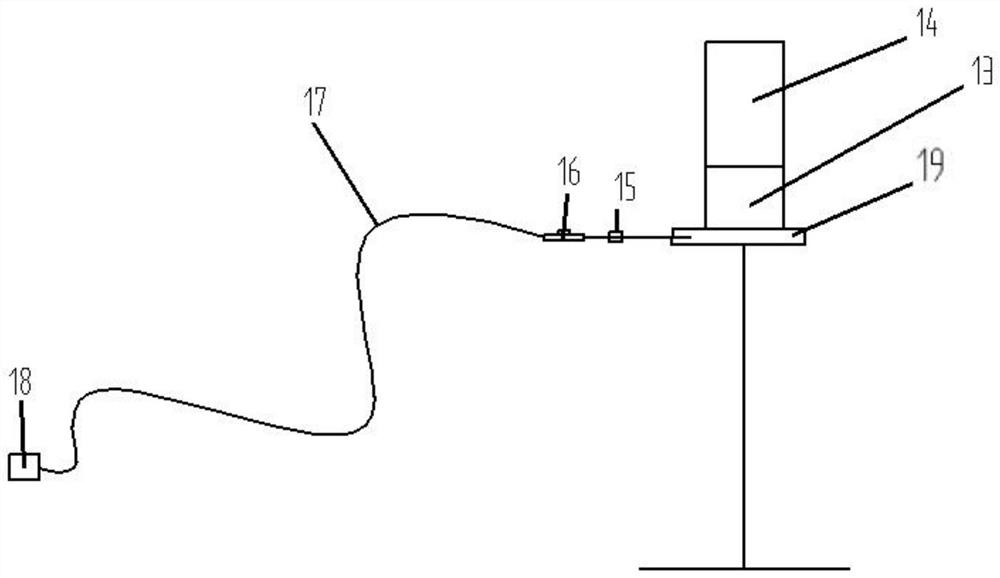

The invention discloses a power takeoff rack test device and a test method thereof, and belongs to the technical field of transmission test. The driving motor is connected with the input end of the first-gear speed increasing box, the output end of the first-gear speed increasing box is connected with the input end of the torque rotating speed sensor, the output end of the torque rotating speed sensor is connected with the power takeoff rack service life testing mechanism, and the power takeoff rack service life testing mechanism is connected with the dynamometer. The clutch gear shifting mechanism is connected with the tested transmission, and the power takeoff gear shifting mechanism is connected with the tested transmission. The tested transmission is checked; the power takeoff rack service life test mechanism is assembled, connected and tested, and a test result is obtained; and the power takeoff rack test device is assembled, connected and tested, and a test result is obtained. The special function under specific conditions can be achieved, and application in the fields of special vehicles, agricultural vehicles and the like is wider and wider; and the power takeoff gear engaging and disengaging test and service life test requirements of a special automobile power takeoff can be met, and then the blank in the field is filled up.

Description

technical field [0001] The invention relates to a power take-off bench test device and a test method thereof, belonging to the technical field of transmission tests. Background technique [0002] Mechanical products are widely used in people's life and production. Like all products, mechanical products have a limited service life. And a lot of practical experience shows that the failure of most mechanical products is caused by the failure of a certain part or some parts. [0003] The power take-off is mainly equipped with shafts, gear teeth and housings, etc. Therefore, it is very necessary to perform bench fatigue test assessment on the above components to ensure the service life of the power take-off. [0004] At present, some models of T18R transmissions have been equipped with power take-offs and occupy a certain amount of the market. Although the new models T19R and T25R also have plans to be equipped with power take-offs, the reliability test assessment based on the b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M17/007G01M13/00

CPCG01M17/007G01M13/00

Inventor 郭琦赵兴天卢洪泉王德春臧运刚盛化哲吕晓龙李嘉博王婷婷侯文杰王喆柏庆军

Owner HARBIN DONGAN AUTO ENGINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com