Soft robot driver

A robot and drive technology, applied in the field of soft robot drives, can solve problems such as performance defects, inability to popularize, and difficulty in satisfying soft robots, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

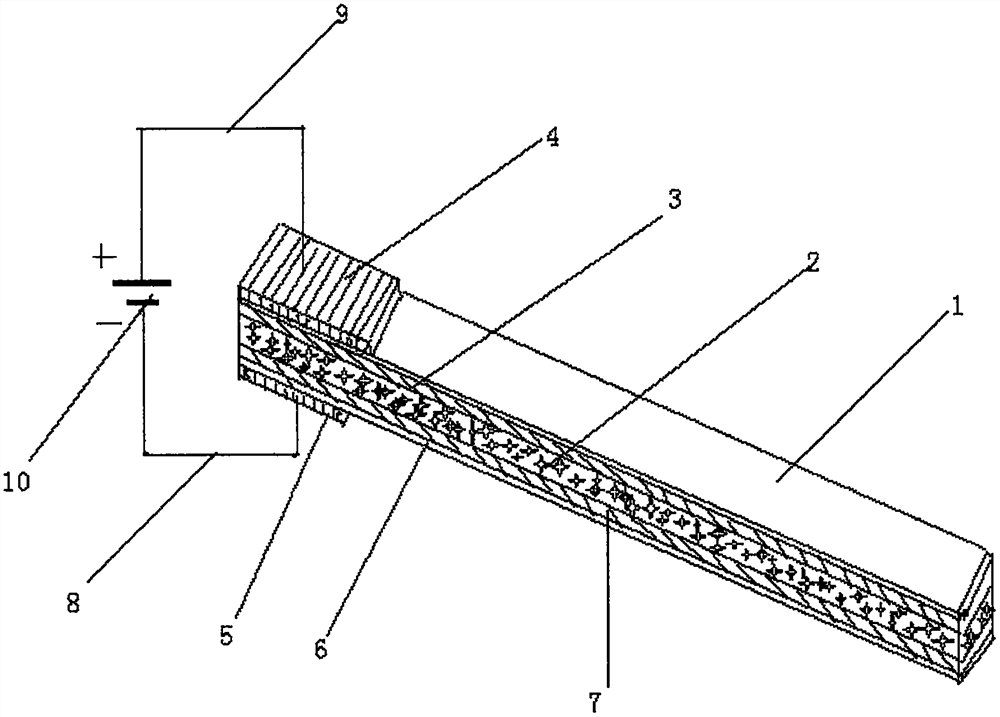

[0009] exist figure 1 In the shown embodiment, upper gold leaf (1), gel (2), upper activated carbon (3), upper copper sheet (4), lower copper sheet (5), lower gold leaf (6), lower activated carbon (7) are provided with. ), the lower wire (8), the upper wire (9), the battery (10).

[0010] A soft robot driver implementing the present invention comprises a gel (2), an upper activated carbon (3) is placed on the gel (2), an upper gold foil (1) is covered on the upper activated carbon (3), and an upper gold foil (1) is placed on the upper activated carbon (3). An upper copper sheet (4) is placed on the top, a lower activated carbon (7) is placed under the gel (2), a lower gold foil (6) is covered under the lower activated carbon (7), and a lower copper sheet ( 5).

[0011] A soft robot driver implementing the present invention, the upper copper sheet (4) is electrically connected to one end of the upper wire (9), the other end of the upper wire (9) is electrically connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com