Automatic dough mixer

A technology of dough mixer and dough cylinder, which is applied in the direction of dough mixer, dough fermenter, mixing/kneading machine structural parts, etc., which can solve the problems of difficult flour mixing, lower work efficiency, and human resource consumption, etc., and achieve improvement tenacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] In order to explain the technical content, constructive features, the purpose and effects of the technical solution, and the specific embodiments are described below, and the accompanying drawings will be described in detail.

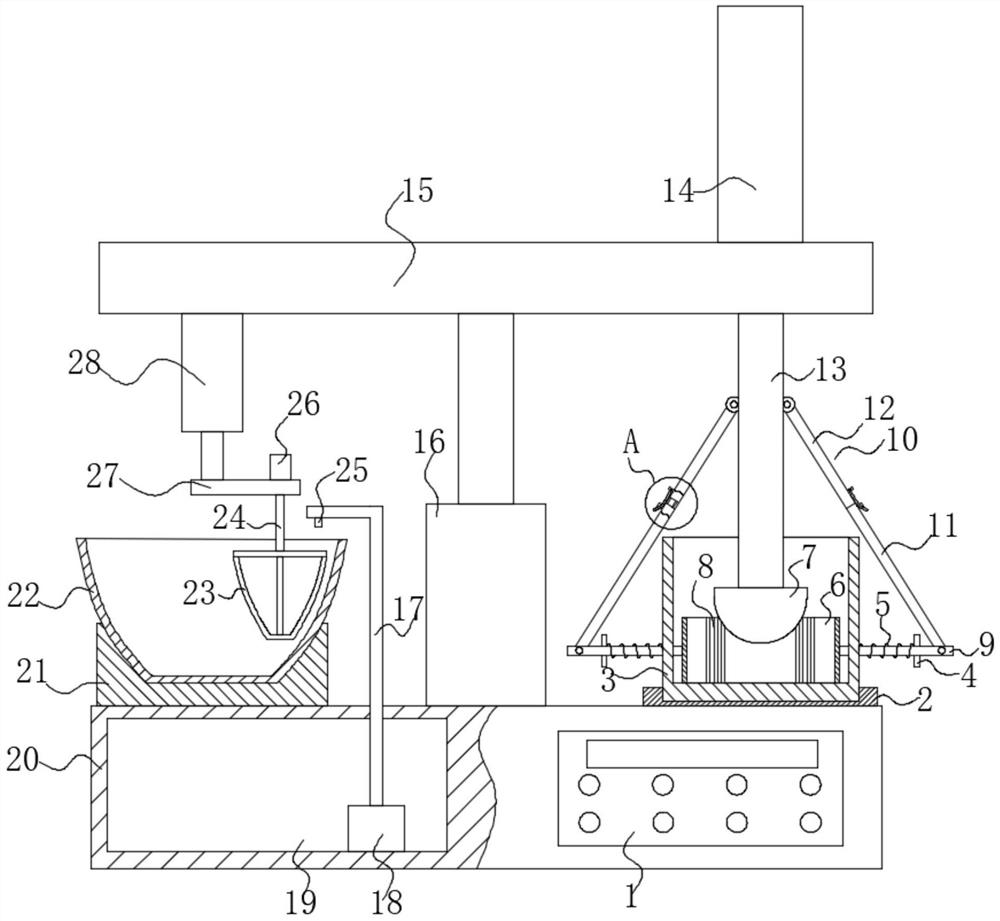

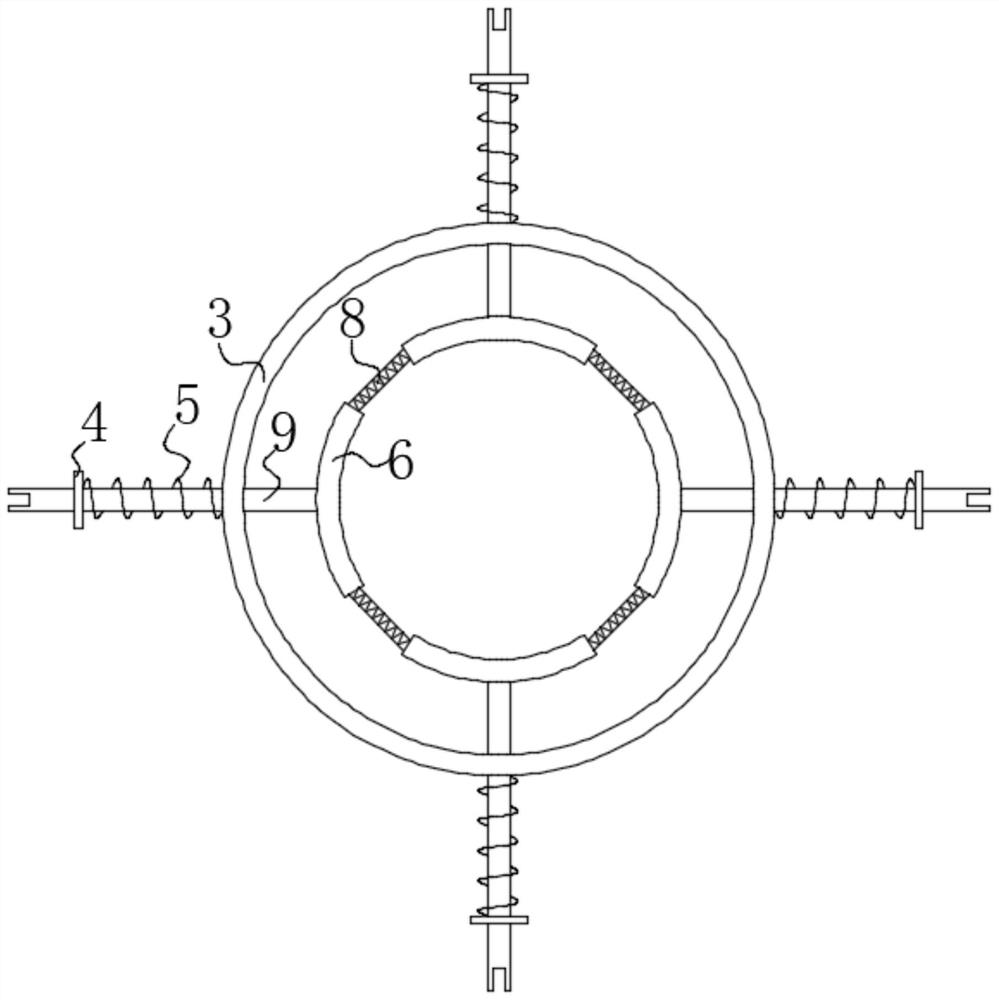

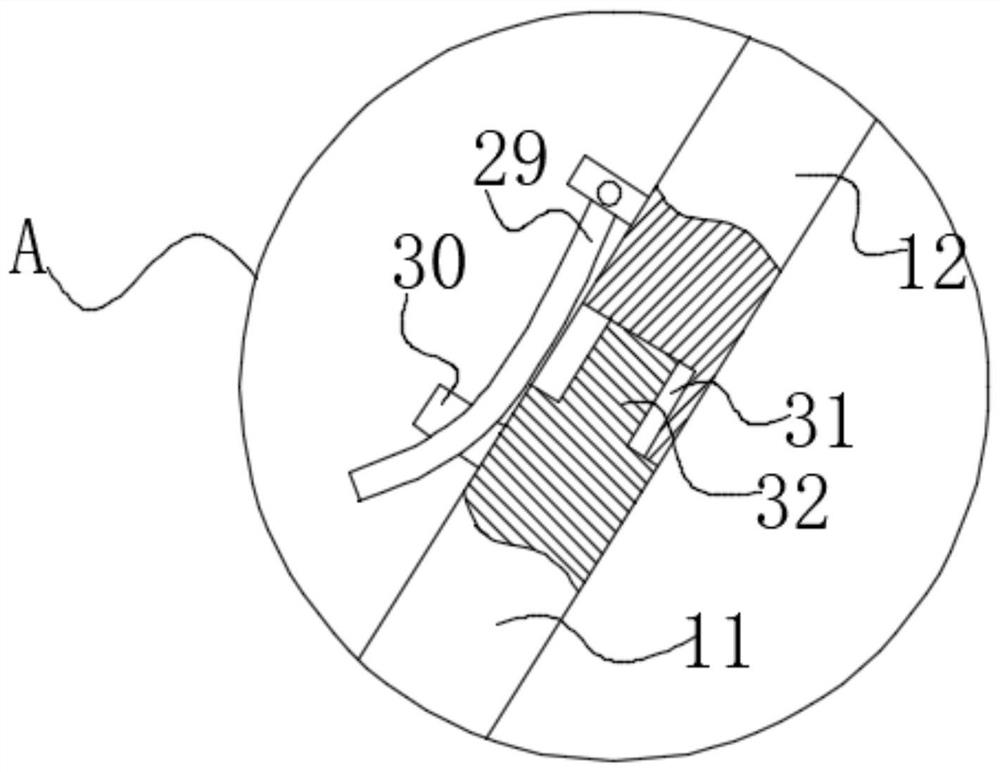

[0021] See Figure 1 ~ 2 , The present embodiment, an automated machine and surfaces, including a base 20, a pressing surface of the cylindrical surface of the cylinder 3 and the mixture 22, the pressing surface of the cylindrical surface of the cylinder 3 and the mixture 22 is provided on the base 20, the base 20 is provided for pressing the stopper surface of the cylinder 3 is a cylindrical seat 2, the lifting plate 15 is provided with a suspension base 20, the pressing surface suspended above the plate cylinder 3 and the surface of the cylinder 22 of the hybrid 15, and the hanging board 15 mounted on the fixed jacking drives the lifting cylinder 16 on the base 20, the suspension plate is provided with mixing means and the hammer face surface means ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap