Tanning device for leather production

A tanning and leather technology, applied in the field of tanning equipment for leather production, can solve problems such as inoperable process and complicated tanning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

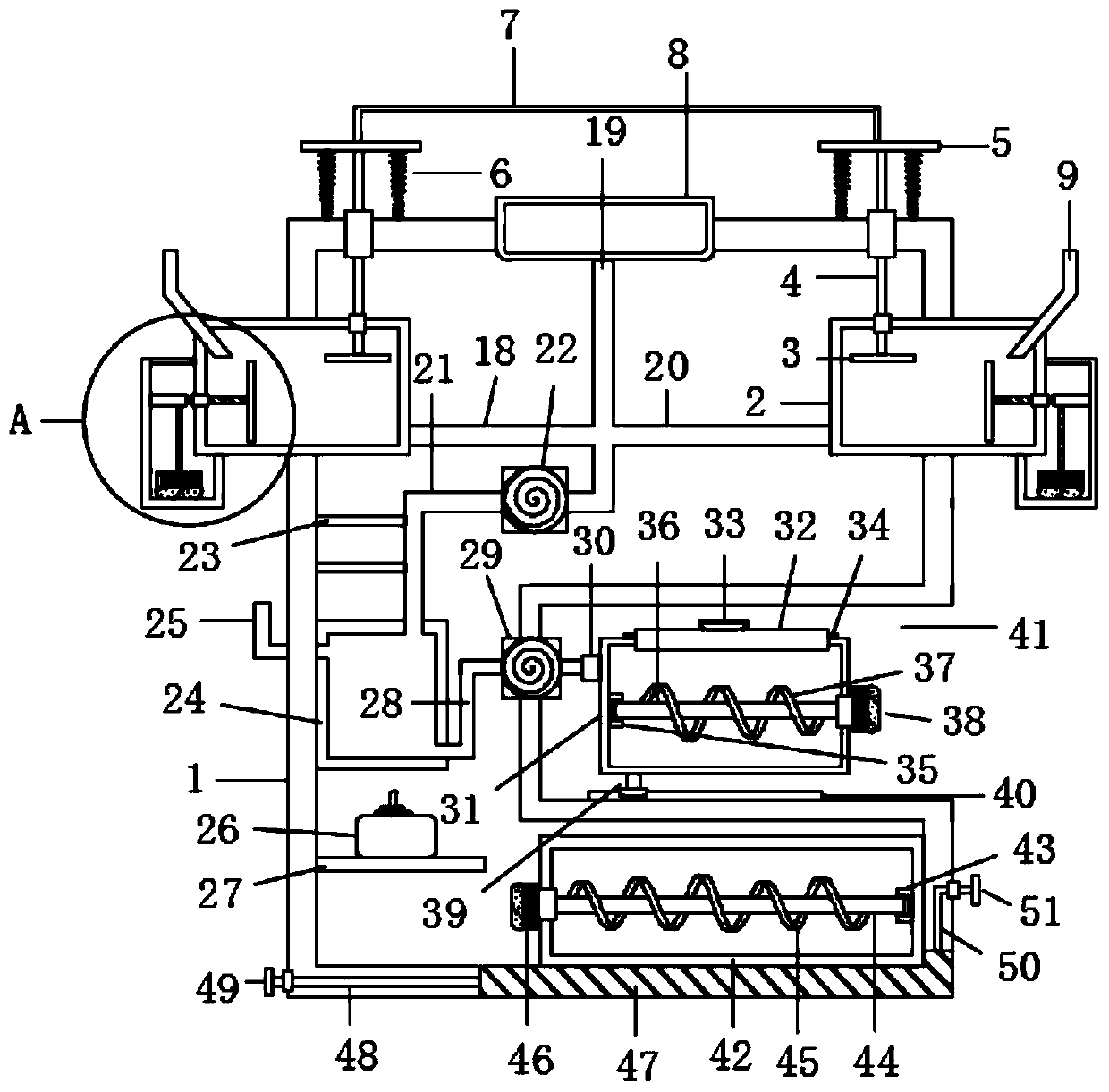

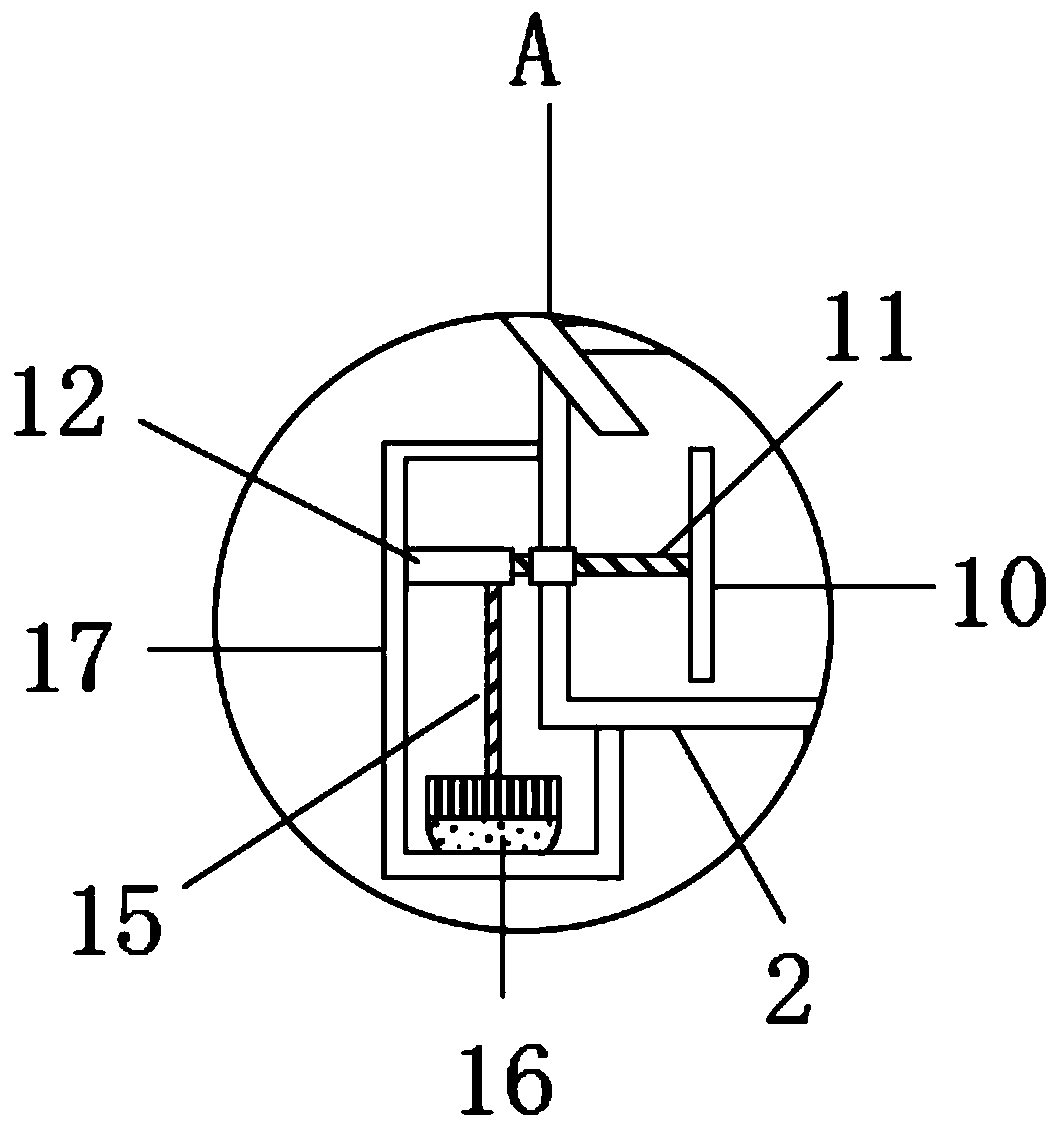

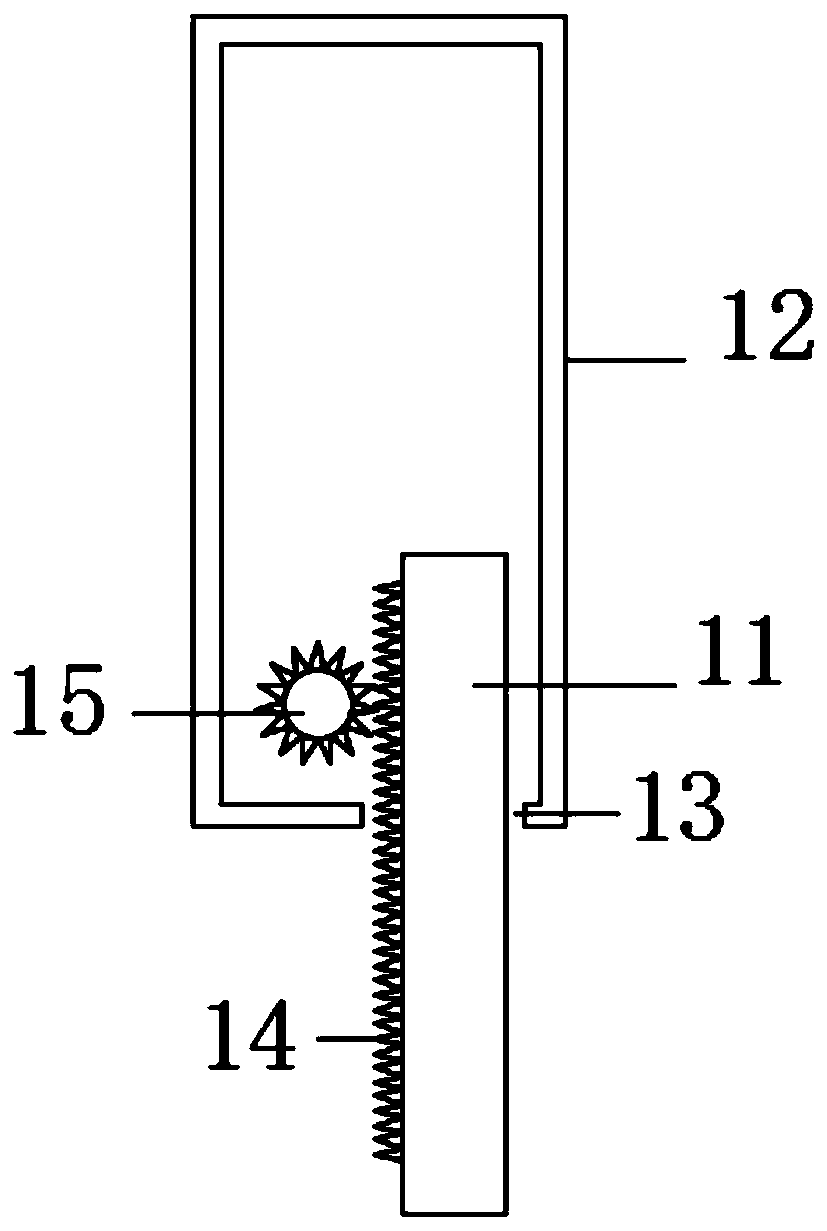

[0025] like Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a tanning device for leather production, including a shell 1, and a crushing box 2 is fixedly installed on both sides above the shell 1, and is used for crushing the No. 1 tanning liquid raw material The composition of the No. 1 tanning solution is red stone fat, amethyst, turpentine and ammonium sulfate, and the upper side of the crushing box 2 is connected with a feed port 9, and the inside of the crushing box 2 is provided with a No. 1 pressing plate 3. A No. 1 connecting rod 4 is fixedly connected to the top of the No. 1 pressing plate 3, and a No. 1 connecting plate 5 is fixedly connected to the other end of the No. 1 connecting rod 4 relative to the interior of the crushing box 2. The No. 1 connecting plate 5 is fixed to the shell 1 A number of springs 6 are connected, and the No. 1 connecting plate 5 is fixedly connected with a No. 1 handle 7 relative to the other end of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap