Method and system for determining number of overhaul layers of shuttle type goods shelf system

A technology for shuttle racks and determination methods, which is applied in the field of determining the number of maintenance floors in the shuttle rack system, can solve the problems of complex determination of the number of maintenance floors and heights, and alleviate the complexity of the determination process of the number of floors and heights , the effect of saving calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

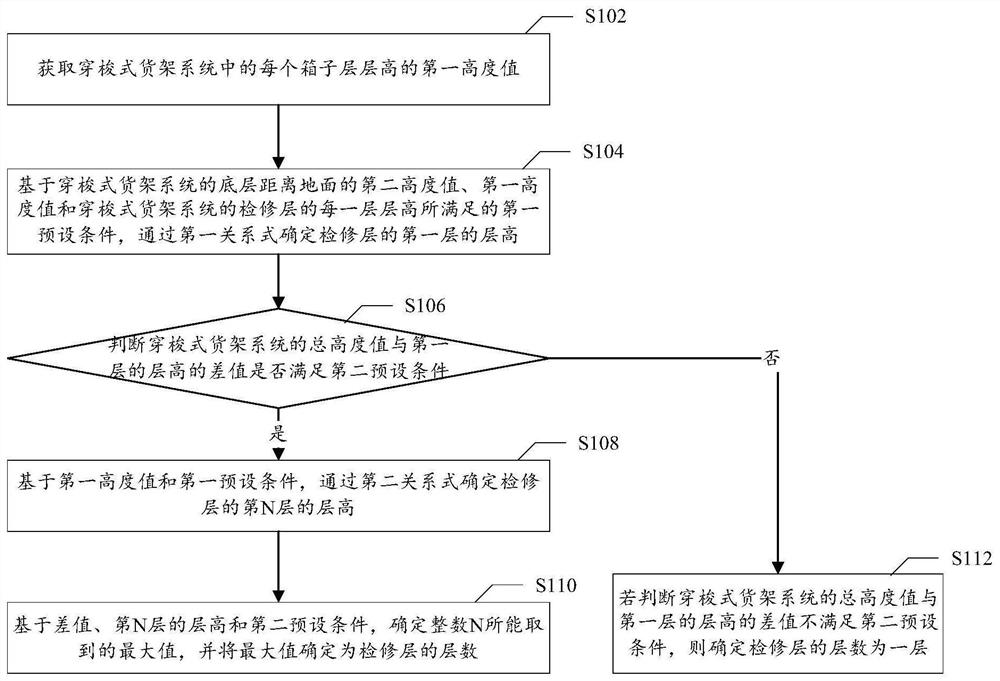

[0021] figure 1 It is a flow chart of a method for determining the number of maintenance floors of a shuttle racking system according to an embodiment of the present invention. Such as figure 1 As shown, the method specifically includes the following steps:

[0022] Step S102, obtaining the first height value of each case layer height in the shuttle racking system.

[0023] Step S104, based on the second height value of the bottom layer of the shuttle racking system from the ground, the first height value and the first preset condition satisfied by the height of each layer of the maintenance layer of the shuttle racking system, through the first relational expression Determine the floor height of the first floor of the inspection floor; the first preset condition includes: the floor height of each floor is greater than or equal to a first threshold and less than or equal to a second threshold.

[0024] Step S106, judging whether the difference between the total height of th...

Embodiment 2

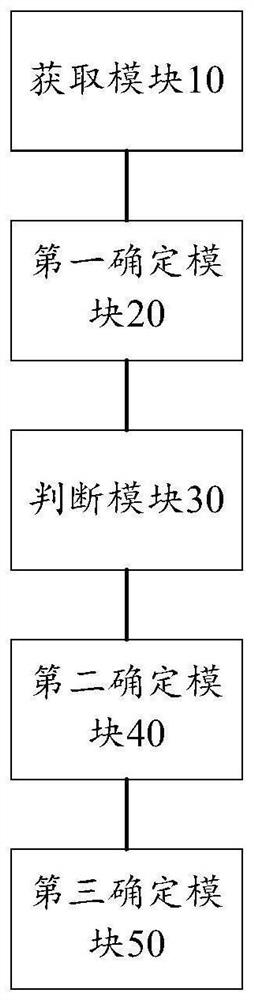

[0044] figure 2 It is a schematic diagram of a system for determining the number of maintenance floors of a shuttle racking system according to an embodiment of the present invention. Such as figure 2 As shown, the system includes: an acquisition module 10 , a first determination module 20 , a judgment module 30 , a second determination module 40 and a third determination module 50 .

[0045] Specifically, the acquiring module 10 is configured to acquire the first height value of each box in the shuttle racking system.

[0046] The first determining module 20 is used to satisfy the first preset condition based on the second height value of the bottom layer of the shuttle racking system from the ground, the first height value and the height of each layer of the inspection layer of the shuttle racking system, The floor height of the first floor of the inspection floor is determined by the first relational expression; the first preset condition includes: the floor height of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com