Mold closing machine for sectional type PC wallboard mold

A segmented, mold clamping machine technology, applied in mold fixtures, mold auxiliary parts, manufacturing tools, etc., can solve the problems of lack of mold clamping equipment and stable splicing without using molds, and achieve the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

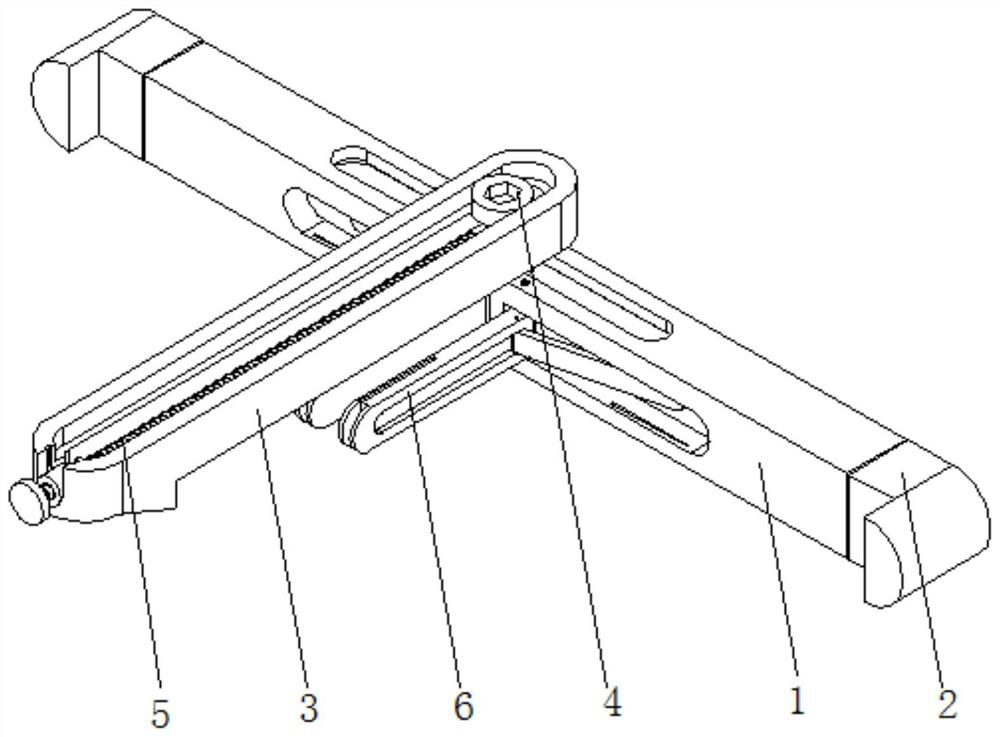

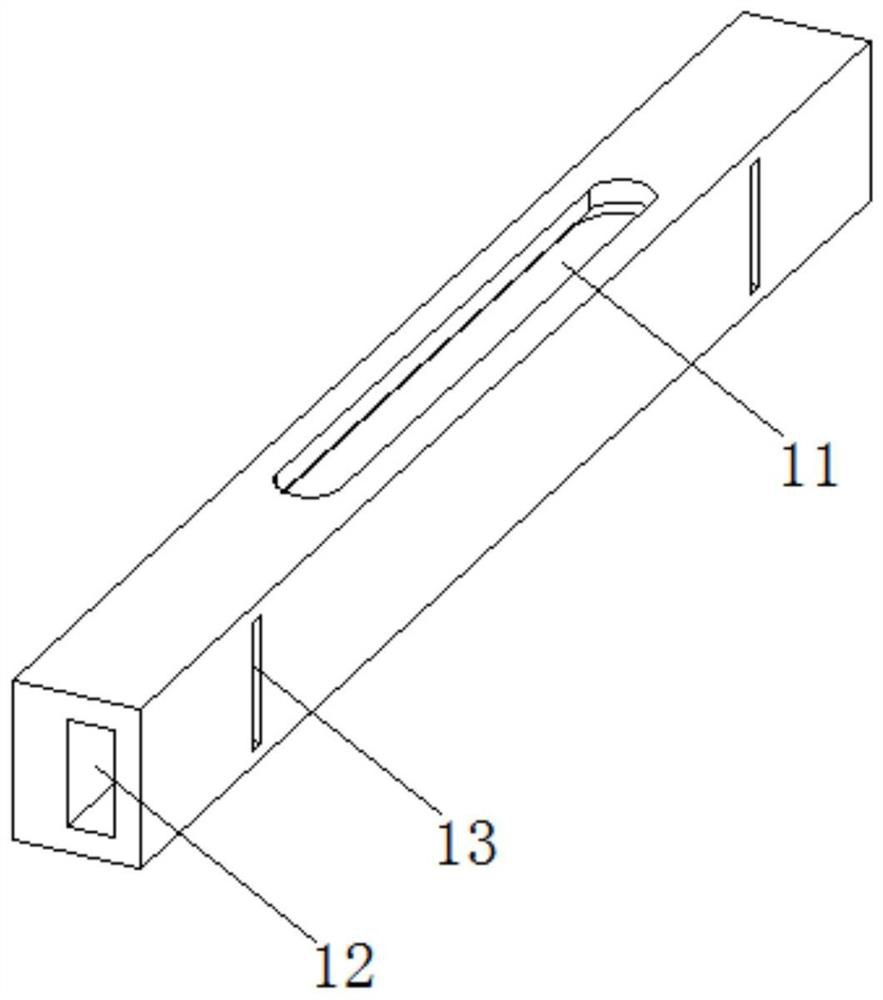

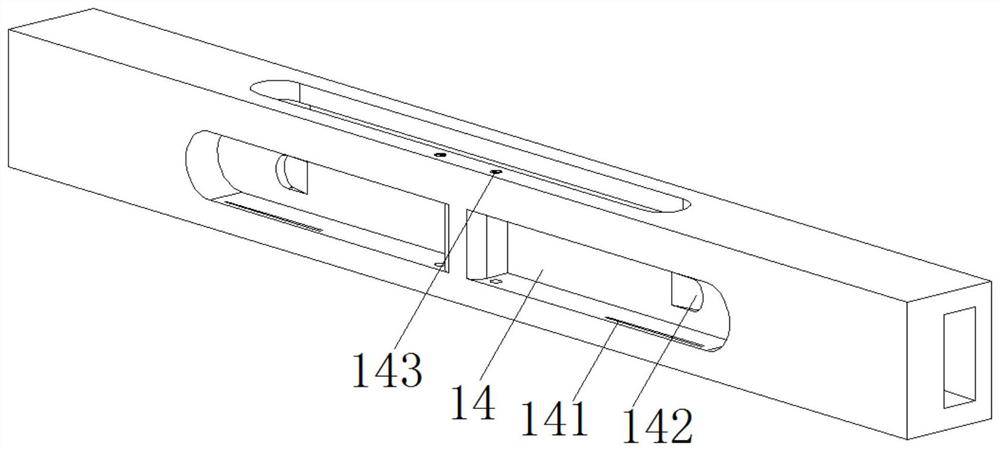

[0025] Example: refer to Figure 1-Figure 8Shown: a mold clamping machine for segmented PC wallboard molds, including a fixed plate group and a connecting plate group, the connecting plate group is located above the fixed plate group, the fixed plate group includes a fixed plate 1, and the upper side of the fixed plate 1 Sliding slots 11 are provided along its length direction, slots 12 are vertically provided on both ends of the fixed plate 1, and the side of the fixed plate 1 away from the mold is vertically provided with a first installation groove 13 on the side of the slot 12 to fix the The side of the plate 1 close to the mold is symmetrically provided with two second installation grooves 14 along its length direction, and the side of the second installation groove 14 away from the mold is provided with abutting groove 142, and the upper and lower sides of the second installation groove 14 are provided along its length direction. There are buckle grooves 141, and one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com