Construction method of side wall of underground structure

A technology of underground structure and construction method, which is applied in the direction of walls, building components, building structures, etc., can solve the time-consuming and labor-intensive problems of cast-in-place side walls, and achieve the effects of improving construction efficiency, shortening construction time, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0036] As a preferred embodiment of the present invention, it also includes:

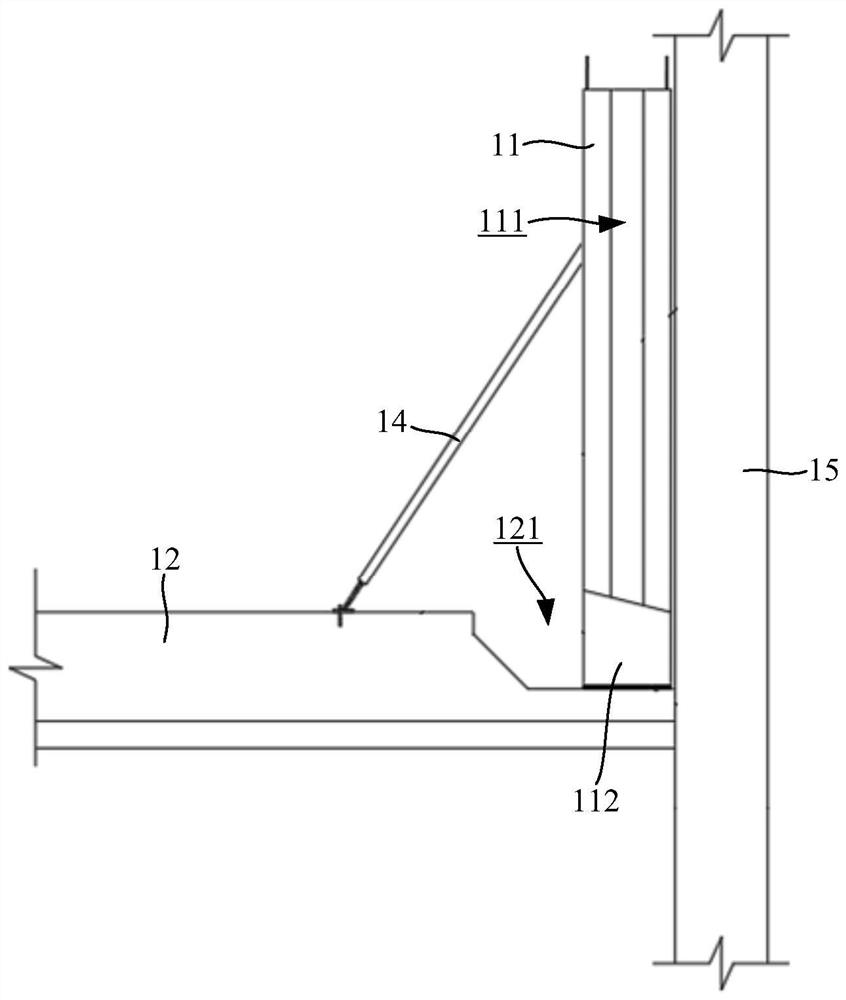

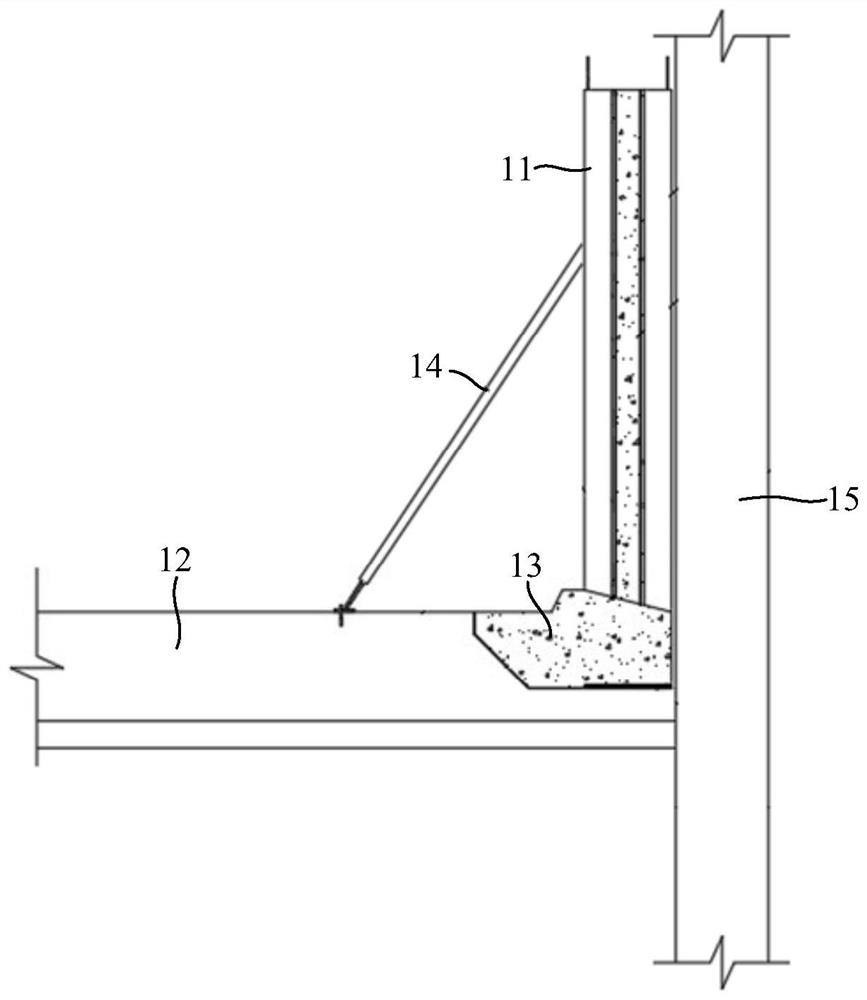

[0037] The diagonal brace 14 is provided, and the diagonal brace 14 is obliquely connected between the prefabricated wall panel 11 and the bottom plate 12 to support and fix the prefabricated wall panel 11. After pouring to form the post-cast structure 13, the diagonal brace 14 is removed.

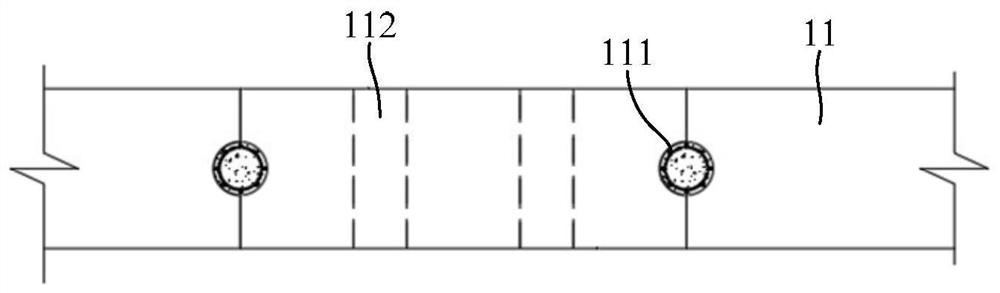

[0038] Further, the bottom of the prefabricated wall panel 11 is provided with several supporting feet 112 at intervals;

[0039] The supporting feet 112 are placed on the bottom surface of the groove 121 , and the supporting feet 112 are buried in the post-casting structure 13 after pouring to form the post-casting structure 13 .

[0040] Specifically, the bottom plate 12 is embedded with bottom plate steel bars, and the part of the bottom plate steel bar corresponding to the groove 121 is exposed outwards, and the bottom of the prefabricated wallboard 11 is pre-embedded with fixing ribs, and the fixing ribs ar...

specific Embodiment approach

[0047] The base plate 12 is formed by pouring at the bottom of the underground structure, and the position of the base plate 12 close to the enclosure structure 15 is depressed downward to form an L-shaped groove 121;

[0048] The prefabricated wallboard 11 is placed close to the enclosure structure 15, and the supporting feet 112 of the prefabricated wallboard 11 are placed on the bottom surface of the groove 121. Since the bottom surface of the groove 121 has a certain slope, some of the supporting feet 112 and the groove 121 There is a gap between the bottom surfaces, and steel plates are filled in the gap;

[0049] Pass the bottom plate steel bars on the upper floor through the support feet 112, bend the bottom plate steel bars on the lower floor upwards and connect them with the fixing bars at the bottom of the prefabricated wall panels 11, and then pour concrete into the grooves 121 to form the post-cast structure 13 , the top surface of the post-cast structure 13 is flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com