Special-shaped micro-channel heat exchange tube type design method, computer equipment and storage medium

A design method and technology of heat exchange tubes, applied in computer-aided design, calculation, design optimization/simulation, etc., can solve the problems of lack of optimal design of heat exchange pipelines, and achieve the effect of simple form and enhanced heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

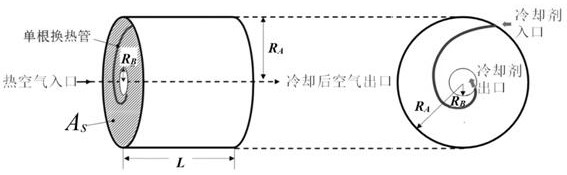

[0051] In order to make the purpose, technical solution and advantages of the disclosed invention more clear, the present invention will be further described in detail below in conjunction with specific embodiments and according to the accompanying drawings. It should be noted that, in the drawings or descriptions in the specification, the content not described and some English abbreviations are the content well known to those of ordinary skill in the art. Some specific parameters given in this embodiment are only for demonstration, and the values may be correspondingly changed to appropriate values in different real-time manners.

[0052] An embodiment of the present invention provides a method for designing a special-shaped microchannel heat exchange tube, including the following steps:

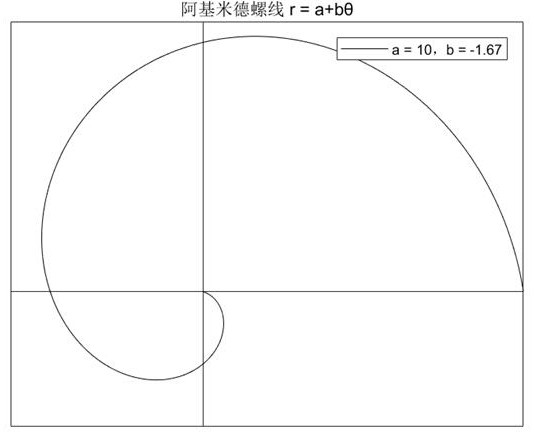

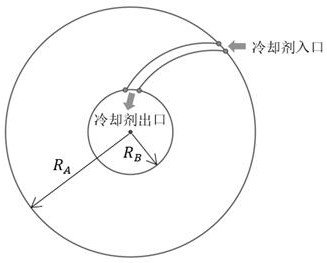

[0053] S1, for figure 1 In the cylindrical heat exchanger shown, the heat exchange tubes arranged in the heat exchanger are all Archimedes spiral heat exchange tubes, and a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com