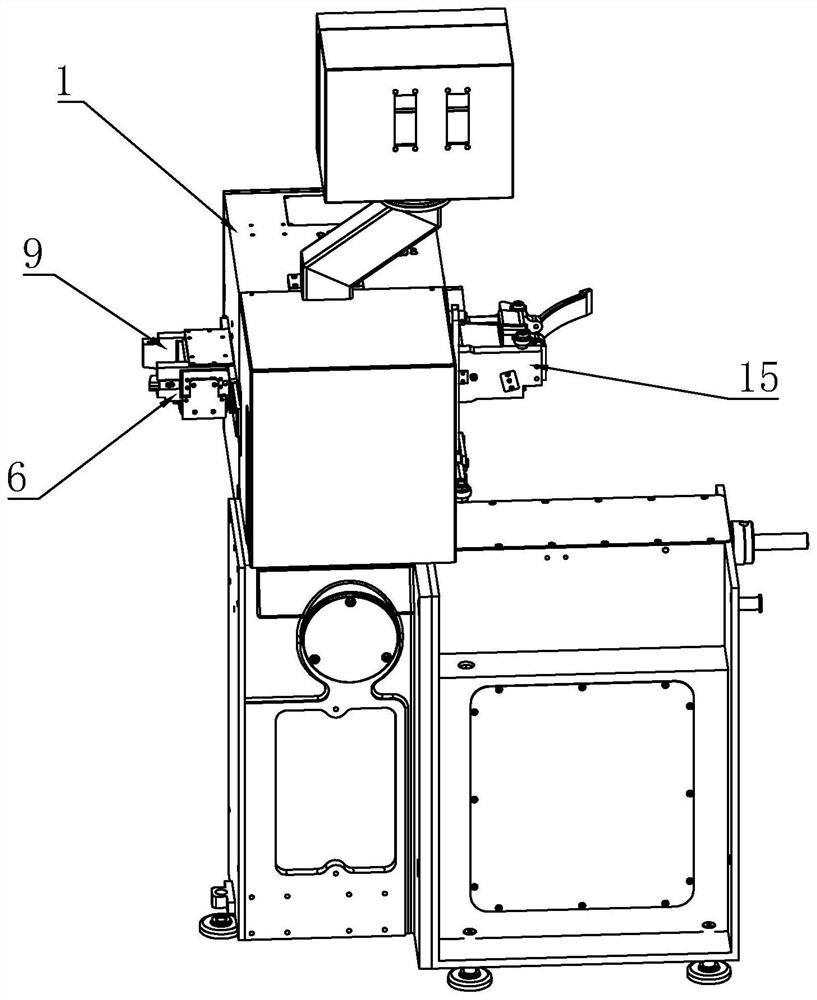

Cigarette case transparent paper six-surface shaping equipment

A cigarette box, transparent technology, applied in the field of six-sided shaping equipment for cigarette box transparent paper, can solve problems such as occupying a large space, affecting work efficiency, and affecting appearance, and achieves high reliability, smooth processing and shaping, and reduced occupied area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

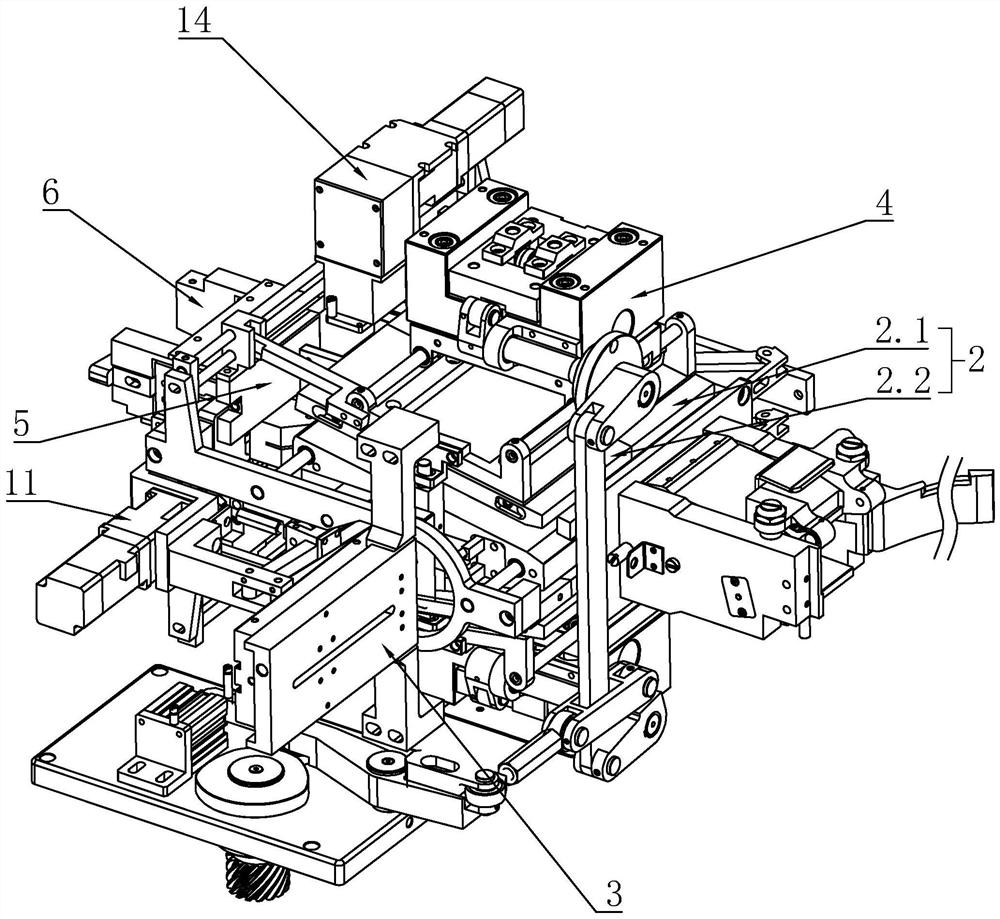

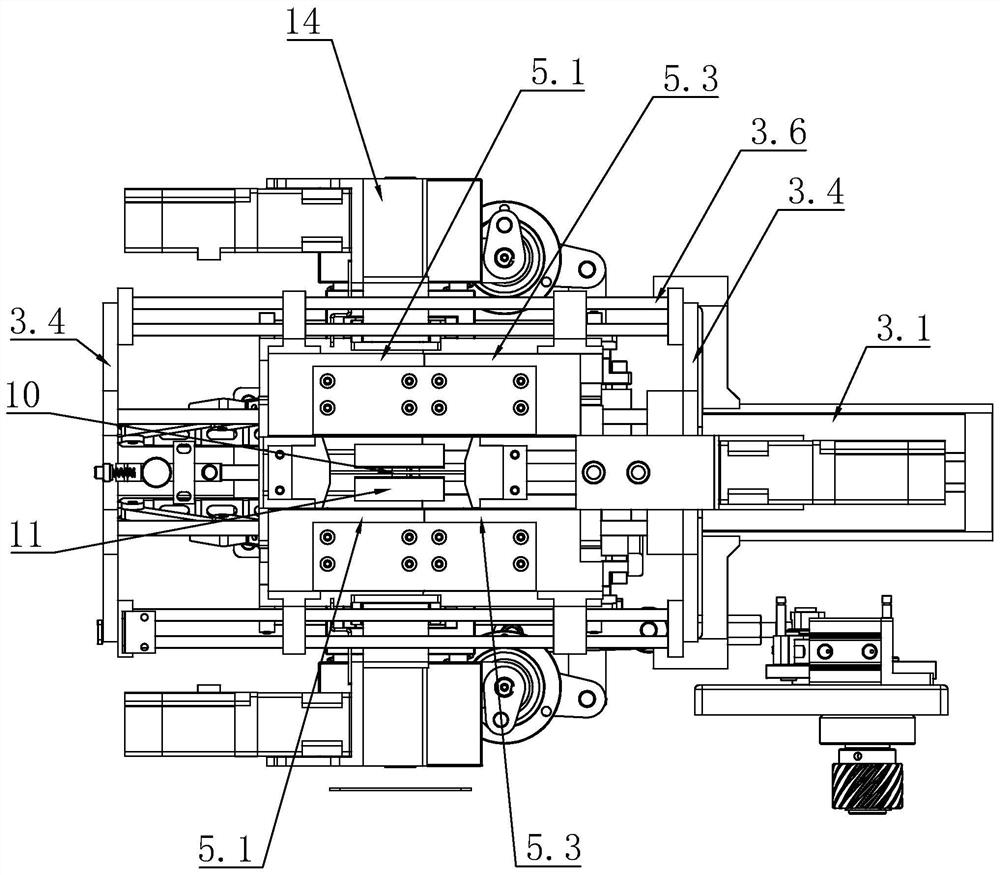

[0061] Such as Figure 1 to Figure 5 and Figure 7 As shown, the upper and lower action mechanism 4 includes a connecting rod assembly 4.1, an upper pressing plate 4.2 and a lower pressing plate 4.3 arranged at both ends of the connecting rod assembly 4.1, the upper pressing plate 4.2 acts on the upper first channel 7, and the lower pressing plate 4.3 Acting on the lower first channel 7, the link assembly 4.1 drives the upper pressing plate 4.2 and the lower pressing plate 4.3 to move relatively, thereby pressing the cigarette case on the first channel 7, wherein the upper pressing plate 4.2 and the lower pressing plate 4.3 There is a first ironing plate 4.4 on the top, and a second ironing plate 7.1 and a second cold plate 7.2 arranged in parallel are arranged on the end surface of the first channel 7. The cold plate assembly includes an upper pressing plate 4.2 and a lower pressing plate 4.3 On the first cold plate 4.5, the first cold plate 4.5 and the first ironing plate 4...

Embodiment 3

[0069] Such as Figure 4 with Figure 8 As shown, the front and rear action mechanism 5 includes a third ironing plate 5.1 arranged on the second channel 8 and clamping assemblies 5.2 arranged on both sides of the second channel 8, and the third ironing plate 5.1 corresponds to the rear of the cigarette case. The end face is set, and the clamping assembly 5.2 clamps the cigarette case falling into the second channel 8 between the third ironing plate 5.1 and the second ironing plate 7.1; the cold plate assembly includes a third ironing plate 5.1- Side of the third cold plate 5.3.

[0070] The clamping assembly 5.2 includes clips 5.21 protruding into both sides of the second passage 8, wherein the clips 5.21 are bent into a block shape, and an oblique guide port is provided at the end of the first passage 7 , the middle of which is bent to form a hollow deformation area 5.23, which elastically compresses the cigarette case.

[0071] Specifically, a press-down mechanism 14 is ...

Embodiment 4

[0073] Such as Figure 6 As shown, the left and right action mechanism 6 includes two fourth ironing plates 6.1 arranged in the third passage 9, and a mobile module 6.2 connected to the two fourth ironing plates 6.1, and the mobile module 6.2 drives two The fourth ironing plate 6.1 moves relatively, thereby compressing the left and right end surfaces of the cigarette case.

[0074] Specifically, the mobile module 6.2 includes a double-head cylinder 6.21 and two sliders 6.22 arranged on the output end of the double-head cylinder 6.21, and a guide rod 6.23 is arranged between the two sliders 6.22.

[0075] Specifically, the push mechanism 11 includes a push head 11.1, a rocker arm assembly for driving the push head 11.1 toward or away from the third channel 9, and a rocker arm electric cylinder. The push head 11.1 is arranged toward the pallet 10, and the The push head 11.1 is provided with a notch 11.11 for the pallet 10 to enter, wherein the rocker arm assembly includes: a co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap