Double-nut lock bolt set and construction method

A technology of anti-loosening bolts and construction methods, applied to nuts, bolts, screws, etc., can solve the problems of increasing the absolute value and discreteness of the torque coefficient of the bolts, high cost of high-quality double-tooth anti-loosening washers, and reducing the anti-loosening ability. , to achieve the effect of improving safety and stability, low anti-loosening cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

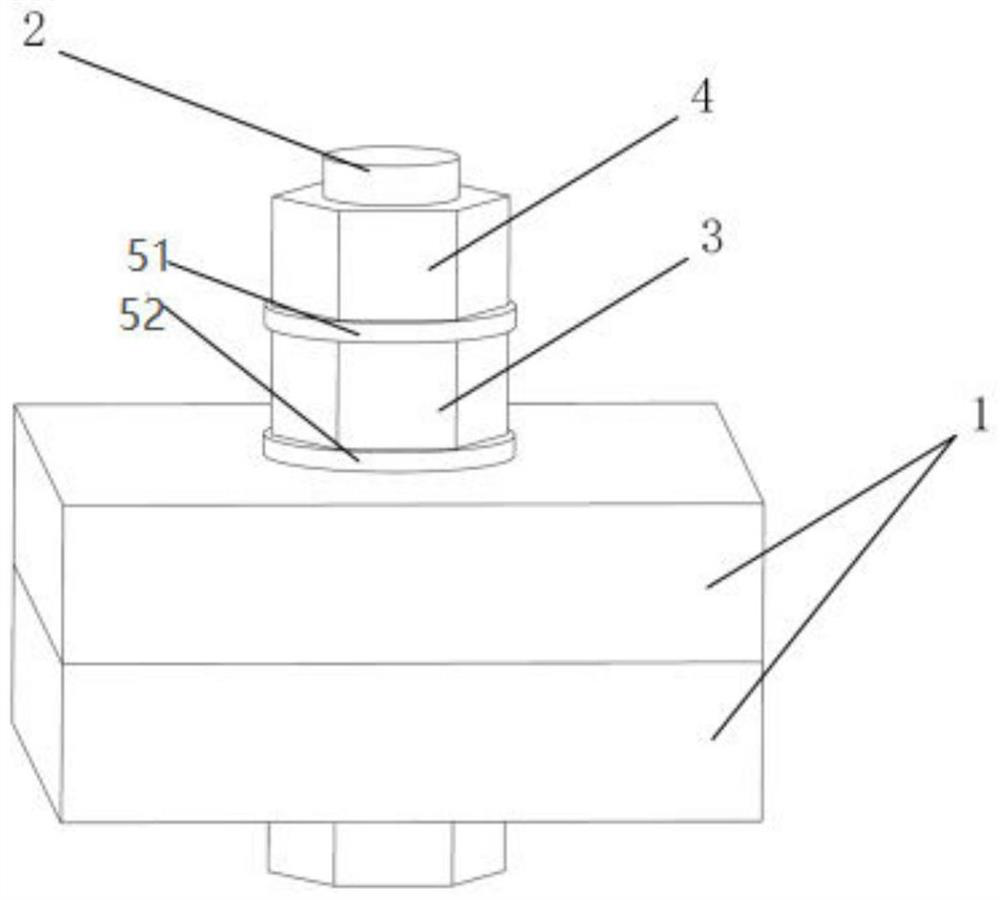

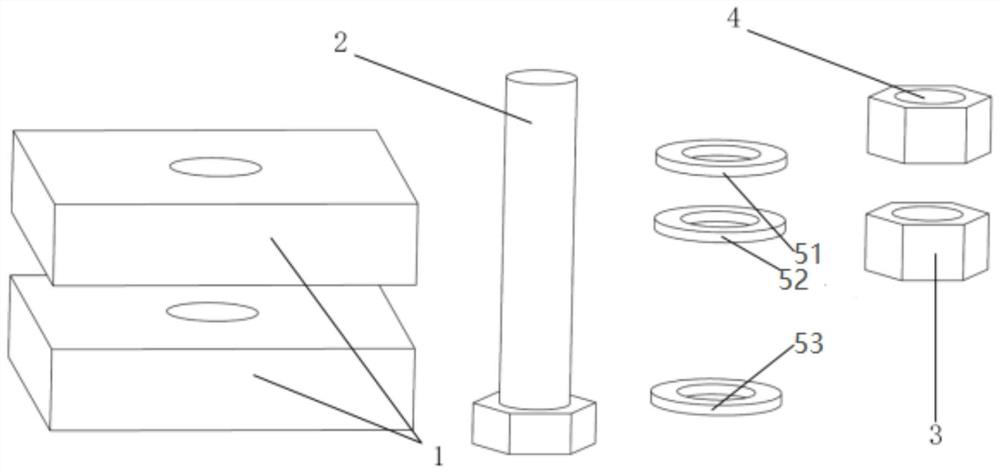

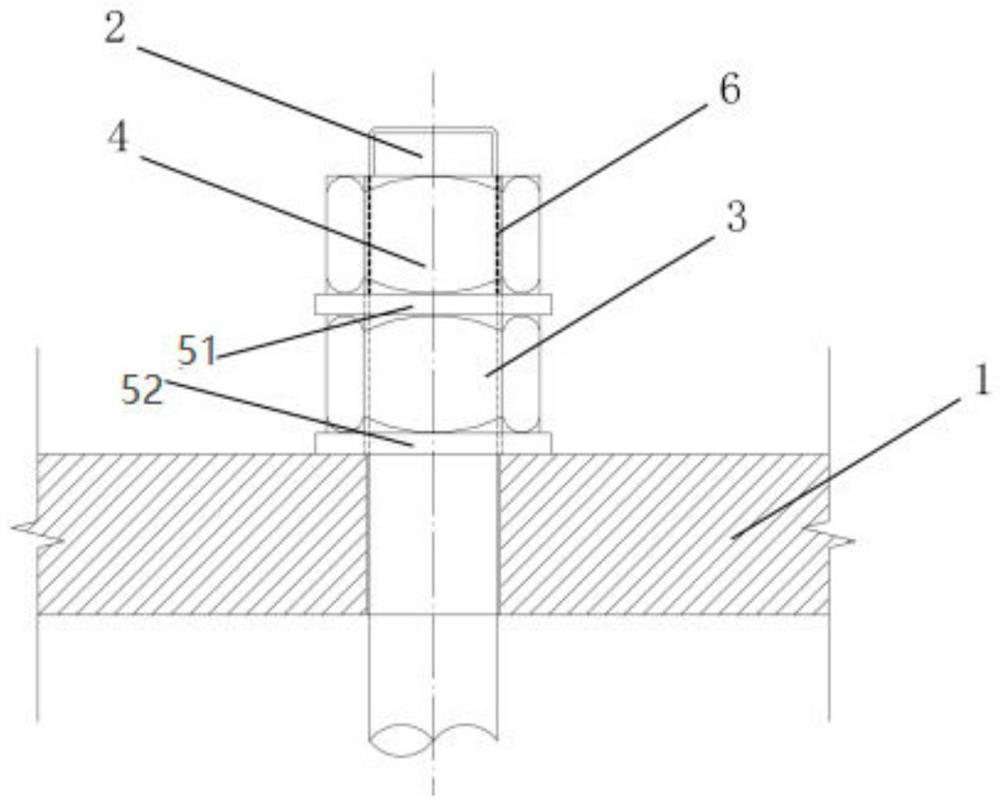

[0031] A two-nut anti-lactor group comprising a high strength bolt 2, a upper nut 4, a lower nut 3, an upper washer 51, the high strength bolt 2, the upper nut 4, the lower nut 3, and the upper washer 51 are both zinc. The high-strength bolt 2 passes through the connecting plate 1, the nut 3 is mounted, and the lower nut 3 is applied with the torque wrench to apply a torque 1T, and the lower nut 3 is applied to the high-strength bolt screw, threaded locking agent 6, and then mount the gasket 51 And the upper nut 4, the upper nut 4 is applied to the upper nut 4 by a torque wrench, and finally the reverse torque of 0.185T is applied to the high strength bolt head, and the bolt residual torque is released.

Embodiment 2

[0033] like figure 1 with image 3 A two-nut anti-lactor group including a high strength bolt 2, a upper nut 4, a lower nut 3, an upper washer 51, a medium washer 52, the high strength bolt 2, the upper nut 4, the lower nut 3, the upper washer 51, medium All the surface of the gasket 52 is a Daclo coating, and the high strength bolt 2 passes through the connecting plate 1, mounting the mine washer 52, the lower nut 3, and the lower nut 3 is applied with a torque wrench to apply torque 1T, and the lower nut 3 is installed after the high strength bolt The screw is applied to the high-strength thread lock reactant 6, thereby mounting the upper gasket 51, the upper nut 4, and the upper nut 4 is applied to the upper nut 4 by a torque wrench, and finally the reverse torque 0.25T is applied to the high strength bolt 2, release bolt residue Torque. Daclo coating is not wear-resistant, the installation process cannot avoid coating damage, after the installation is completed, the inorganic z...

Embodiment 3

[0035] like figure 2 , A two-nut anti-lactor group includes a high strength bolt 2, a upper nut 4, a lower nut 3, an upper washer 51, a medium washer 52, a lower washer 53, and passes the high strength bolt 2 through the lower washer 53, the connecting plate 1, mount Medium washer, lower nut 3, using a torque wrench to apply a torque 1T, after the lower nut 3 is installed, the threaded locking agent 6 is applied to the high-strength bolt, and the upper gasket 51 and the upper nut 4 are mounted, and the torque wrench is utilized. The torque 1.1T is applied to the upper nut 4, and finally the reverse torque of 0.185t is applied to the high strength bolt head, and the bolt residual torque is released.

[0036] Example 1, Example 2, Example 3 proposed a two-nut anti-lamination bolt group and construction method, by realizing the bolt preloading force in a non-lubricating grease installation environment, through a non-lubricating grease installation environment Establish a reliable dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com