A supercooling maintenance device for pulse thermoelectric refrigeration capable of heat recovery

A technology of thermoelectric refrigeration and heat recovery, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc. It can solve the problems of limited refrigeration temperature, the heat of semiconductor refrigerators cannot be recycled, and the temperature rises.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

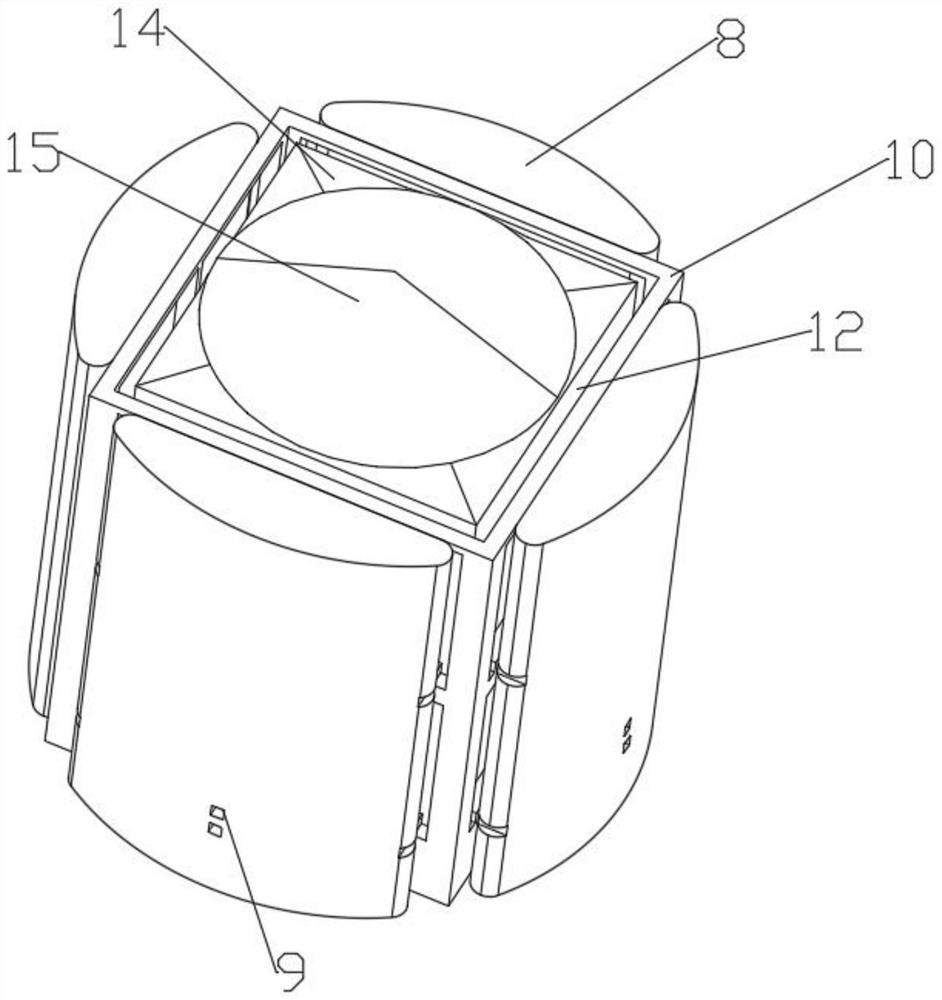

[0037] The thermoelectric refrigeration mechanism is set to include 4 sets of thermoelectric refrigeration units, and materials such as lg-6 isostatic graphite, heat insulation board, 6061 aluminum, semiconductor refrigerator (TEC), and semiconductor thermoelectric generator (TEG) are used to further improve the model. On this basis, the physical object was built, and some experiments were carried out on the basis of the physical object, which preliminarily verified the feasibility of the principle design of this project.

[0038] Estimated energy consumption calculation:

[0039] Electric energy recovery rate: α=TEG output power / external input pulse current power=66.29 / 1040.70*100%=6.37%;

[0040] Subcooling degree = (DC optimal steady-state temperature - transient supercooling temperature) / optimal steady-state temperature = (260K-249.41K) 260K*100%=4.07% (calculated in degrees Celsius);

[0041] Original cooling efficiency = (other parts cooling object temperature - stead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com