Battery wiring module and flexible substrate with electronic component

A technology of flexible printing and electronic components, applied in the direction of printed circuits, printed circuits, battery pack components, etc., to achieve the effect of stable protection function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0046] refer to Figure 1 to Figure 5 Embodiment 1 will be described. A flexible printed circuit board with a current limiting element (hereinafter simply referred to as "FPC with a current limiting element") 1 of this embodiment is used for a battery module 3 mounted in a vehicle 2 such as an electric vehicle or a hybrid vehicle.

[0047] Such as figure 1 As shown, the battery module 3 is disposed near the center of the vehicle 2 . A PCU (Power Control Unit) 4 is arranged at the front of the vehicle 2 . The battery module 3 and the PCU 4 are connected by a wire harness 5 . The battery module 3 has a plurality of power storage elements 6 . The power storage element 6 may be a secondary battery such as a nickel-metal hydride secondary battery or a lithium-ion secondary battery, or may be a capacitor.

[0048] (battery module 3)

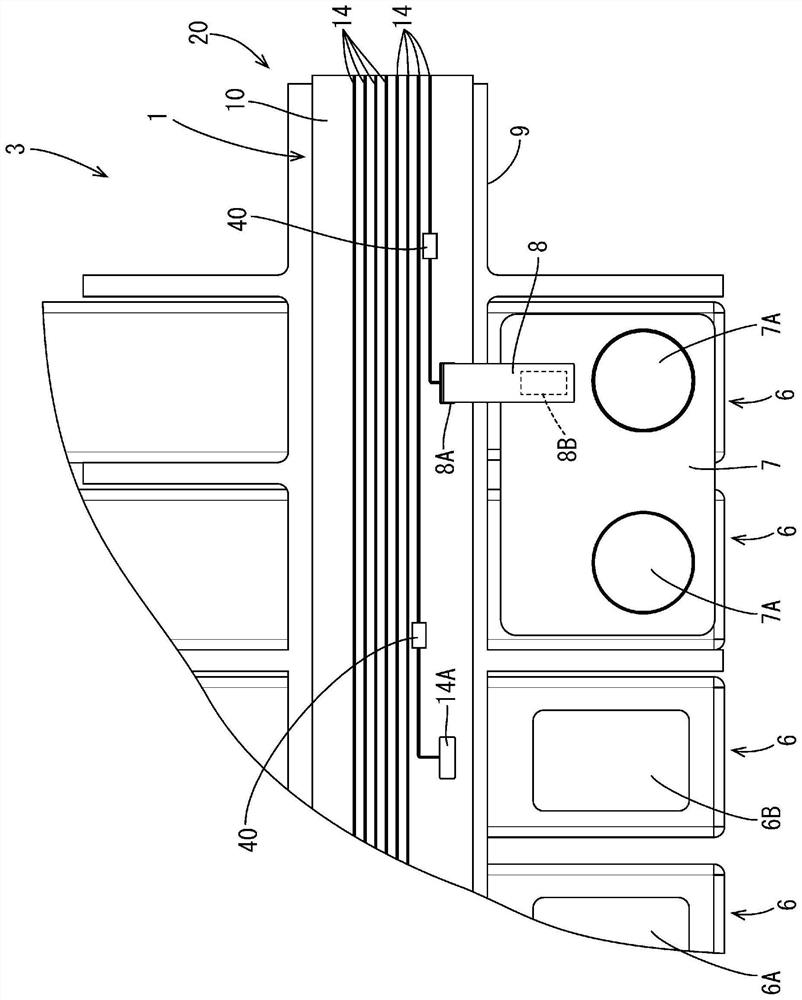

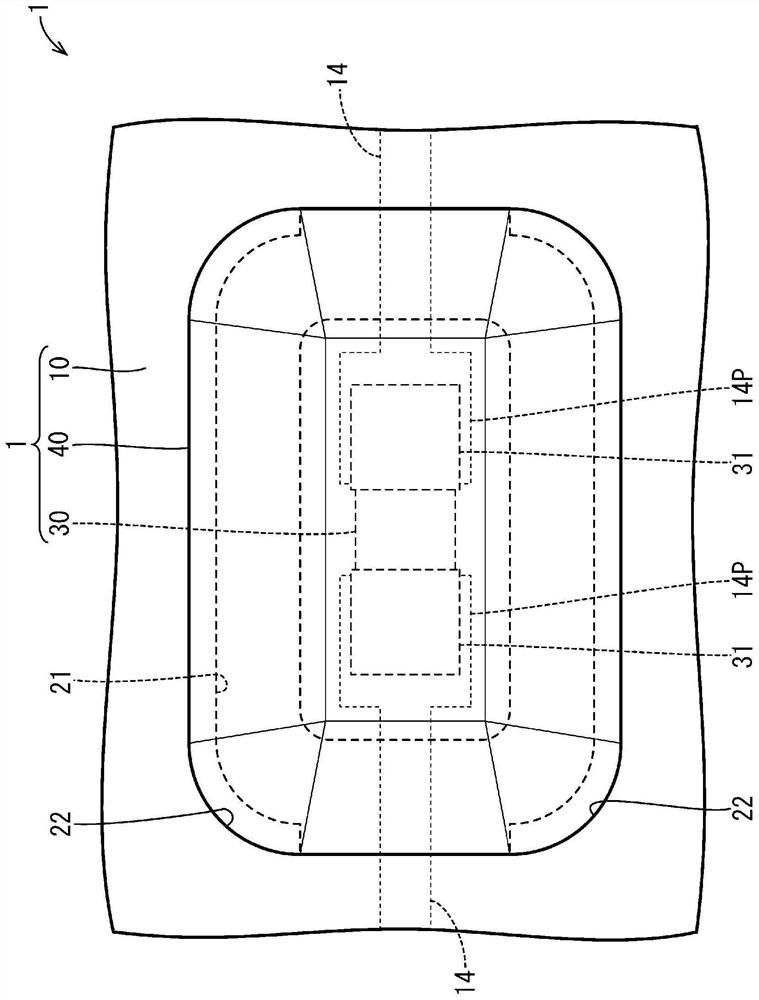

[0049] Such as figure 2 As shown, each storage element 6 is in the shape of a flat rectangular parallelepiped, accommodates a storage element ...

Embodiment approach 2

[0081] Next, refer to Figure 6 and Figure 7Embodiment 2 will be described. As in the first embodiment, the FPC 50 with a current limiting element of this embodiment is used for the battery module 3 . The FPC 50 with a current limiting element is different from the first embodiment in that the surface of the cover film 53 of the FPC 51 has a laminated structure 56 (corresponding to a limiting portion and a limiting protrusion) protruding from other parts. The same reference numerals are assigned to the same configurations as those in Embodiment 1 in this embodiment, and description thereof will be omitted.

[0082] Such as Figure 6 As shown, the FPC 50 with a current limiting element includes an FPC 51 , a current limiting element 30 mounted on the FPC 51 , and an insulating element covering portion 57 covering the current limiting element 30 .

[0083] Such as Figure 7 As shown, the FPC 51 includes an insulating base film 11, a conductive path 14 and two regulation li...

Embodiment approach 3

[0097] Next, refer to Figure 8 and Figure 9 Embodiment 3 will be described. As in the first embodiment, the FPC 60 with a current limiting element of this embodiment is used for the battery module 3 . The FPC 60 with a current limiting element differs from the first embodiment in that the FPC 61 includes a substrate main body 62 and a laminated portion 66 (corresponding to a restricting portion and a restricting protrusion) overlapping the substrate main body 62 . The same reference numerals are assigned to the same configurations as those in Embodiment 1 in this embodiment, and description thereof will be omitted.

[0098] Such as Figure 8 As shown, the FPC 60 with a current limiting element includes an FPC 61 , a current limiting element 30 mounted on the FPC 61 , and an insulating element covering portion 67 covering the current limiting element 30 .

[0099] Such as Figure 9 As shown, the FPC 61 includes a substrate main body 62 and a lamination portion 66 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com