Multi-shaft thread synchronous tightening control method

A control method and thread technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of unfavorable simultaneous tightening of multiple bolts, insufficient tightening synchronization, and reduced bolt pre-tightening force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

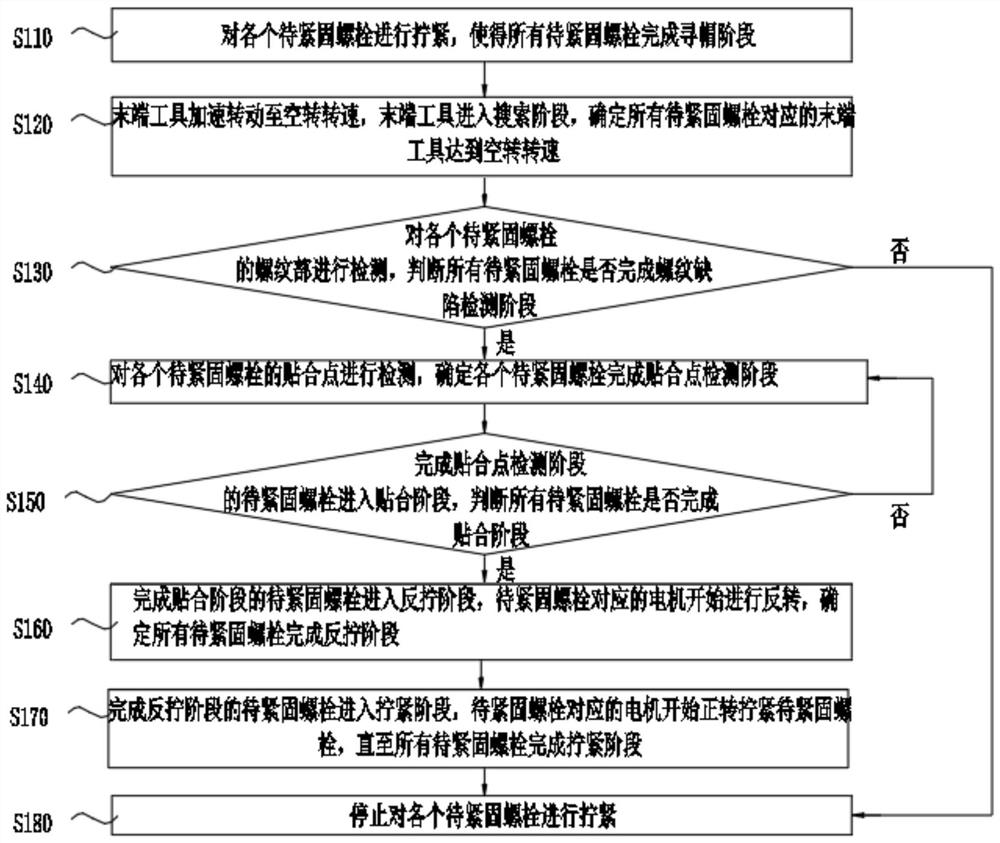

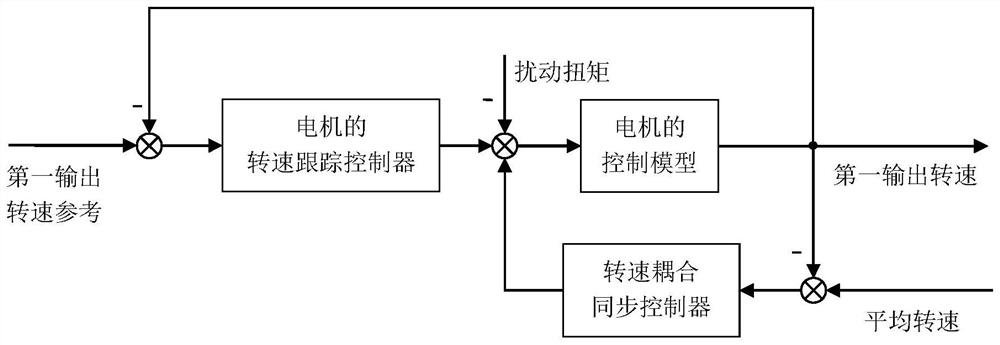

[0051] Such as figure 1 and figure 2 As shown, a multi-axis thread synchronous tightening control method of the present invention is used for tightening a multi-axis system composed of multiple bolts to be tightened. In the multi-axis system, each bolt to be tightened corresponds to a tightening axis. The multi-axis thread synchronous tightening control method includes the following steps:

[0052] Step S110, tighten each bolt to be fastened, so that all the bolts to be fastened complete the stage of searching for caps, and realize the initial docking operation between the end tool and the bolt head of the bolt to be fastened; wherein, the completion of the stage of searching for caps refers to the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com