Structural body crack sub-pixel detection method

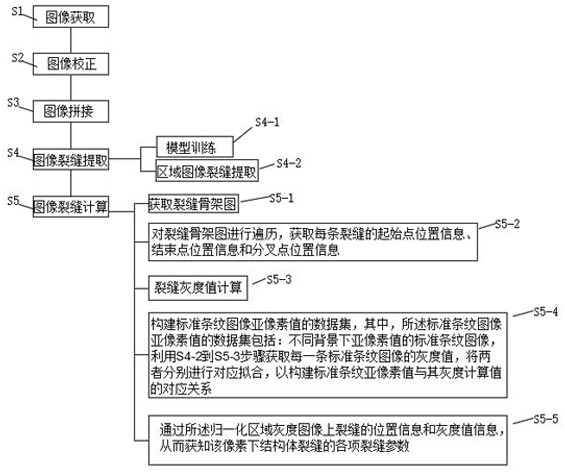

A detection method and structure technology, applied in image analysis, image data processing, graphic image conversion and other directions, can solve the problems of inability to realize sub-pixel crack image recognition, inability to identify cracks, etc., to reduce the number of captured images, improve Crack detection accuracy and the effect of improving crack detection resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

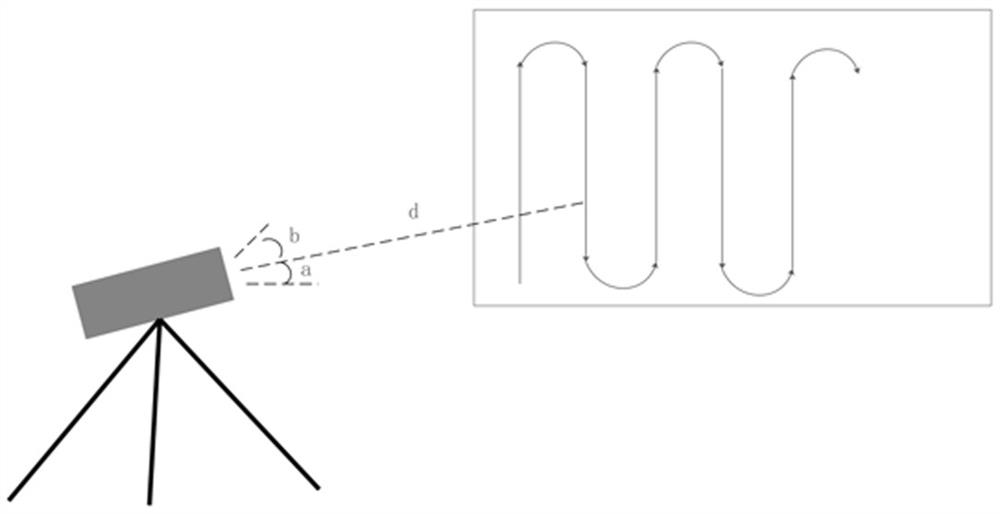

[0149] For the known width of the structural crack, which is 0.1mm to 1mm, adjust the position of the shooting camera to the case where the calibration coefficient is g(d)=1(mm / pixel), and adjust the distance between the shooting camera and the shooting plane (that is, the structural crack) Distance, to adjust the pixel value of the captured structural crack on the image, so that the width of the structural crack corresponds to the pixel value, that is, the pixel value corresponding to a crack with a width of 0.1 is 0.1, and the pixel value corresponding to a crack with a width of 0.2 is 0.2...and so on.

[0150] By adopting the structure crack sub-pixel detection method of the present invention, the comparison chart between the actual measured width value and the known width is obtained as follows. Wherein, the crack width unit: mm. Table 1 is the comparison chart between the actual measured width value and the known width of standard sample 1~standard sample 15, and table 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com