Microporous polyolefin membrane, separator for secondary batteries, and secondary battery

A technology of microporous membrane and secondary battery, applied in battery pack parts, separators/films/diaphragms/spacer elements, membranes, etc., can solve problems such as reduced thermal stability of electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

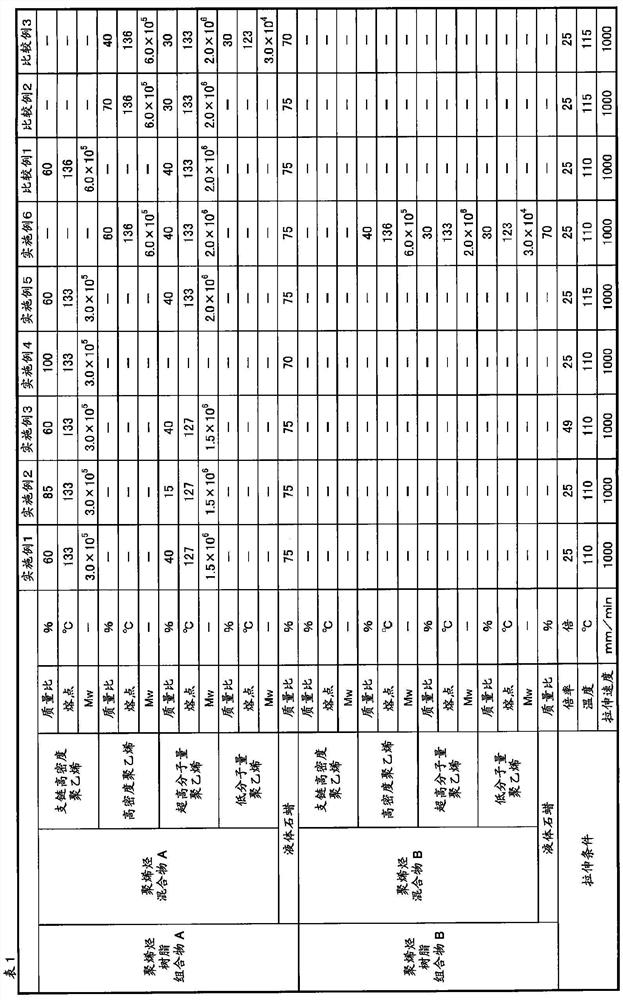

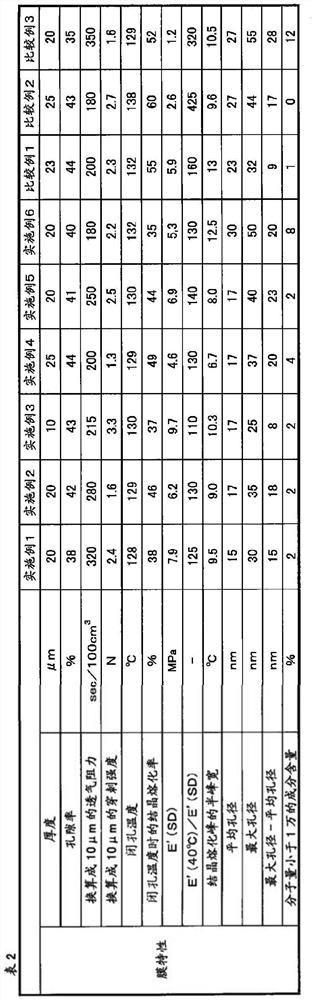

[0168] (Example 1)

[0169] The weight average molecular weight (Mw) of 1.5 × 10 6 Mp 127 ℃ ultrahigh molecular weight polyethylene and 40% by mass weight-average molecular weight (Mw) of 3.0 × 10 5 , High-density branched polyethylene melting point 133 ℃ mixing 60% by mass, it is set to a polyolefin mixture A. By the above-mentioned polyolefin mixture and 24.8% by mass as an antioxidant, tetrakis [methylene-3- (3,5-di-t-butyl-4-hydroxyphenyl) - propionate] methane, 0.2% by mass obtained by mixing substance into the twin screw extruder, a biaxial extruder from the side feeder feed liquid paraffin 75% by mass of the machine, and at 200 ℃ 250rpm, Q / Ns = 0.2 melt-kneaded under the conditions, to prepare a polyolefin resin composition A. A polyolefin resin composition was fed to a T-die, extruded as a sheet, a cooling roll adjusted to a temperature of 30 deg.] C while pulling speed at 4m / min traction while cooling, a gel-like sheet formed.

[0170] The resulting gel-like sheet so ...

Example Embodiment

[0171] (Example 2)

[0172] The weight average molecular weight (Mw) of 1.5 × 10 6 , 127 deg.] C melting point of ultrahigh molecular weight polyethylene 15% by mass, weight average molecular weight (Mw) of 3.0 × 10 5 , High density polyethylene, m.p. 85 deg.] C to 133 mass% branched mixed, to which a mixture of polyolefin A, except that, in Example 1 in the same manner to obtain a polyolefin microporous membrane.

Example Embodiment

[0173] (Example 3)

[0174] The resulting gel-like sheet so as to be a quadrangular manner 80mm square was cut out, so as to be in the MD direction at a stretching temperature 110 ℃, a tensile speed of 1000mm / min 7 times, becomes 7 times in the TD direction manner simultaneous biaxial stretching carried out, except that in Example 1 to obtain the same manner as the polyolefin microporous membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Half width | aaaaa | aaaaa |

| Puncture strength | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap