Roadbed filling construction method

A construction method and filling technology, applied in the directions of roads, buildings, roads, etc., can solve the problems of the impact of the subgrade surface leveling work, the bumps of the grader, etc., and achieve the effect of improving stability and reducing deflection and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

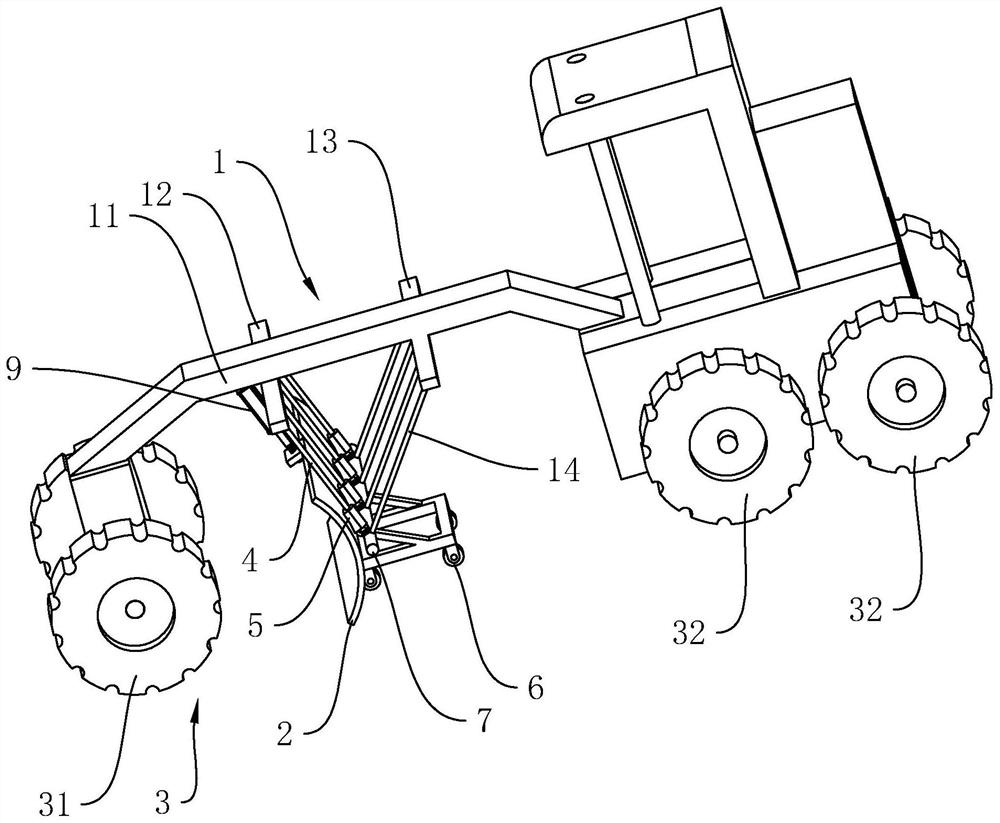

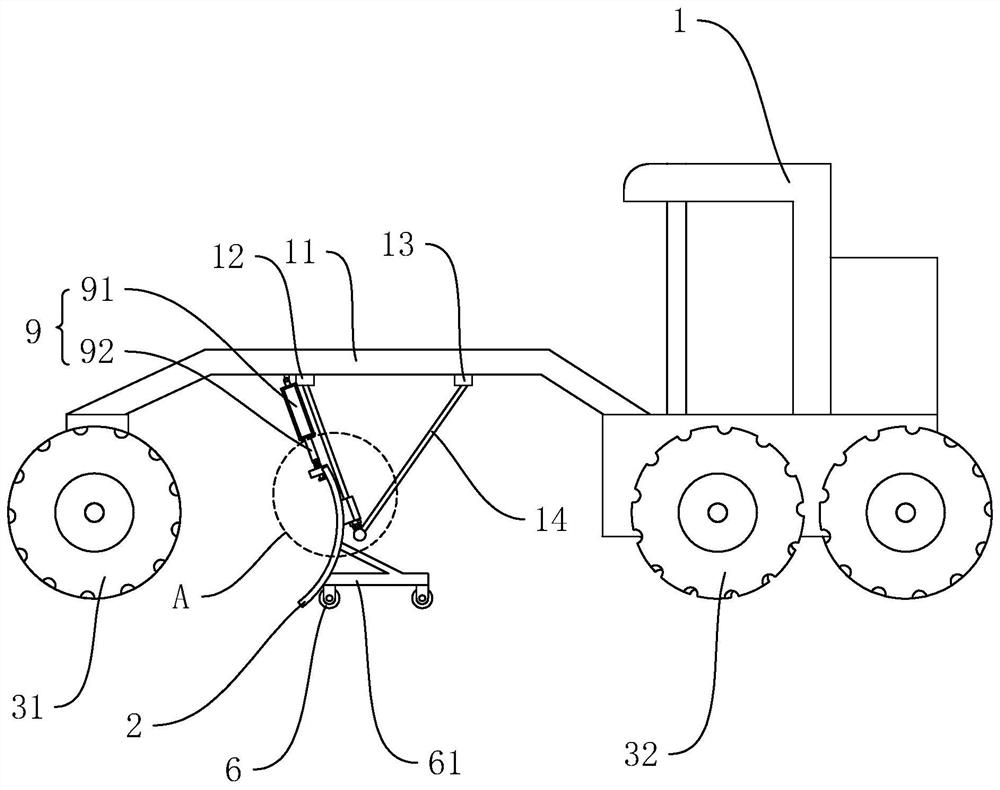

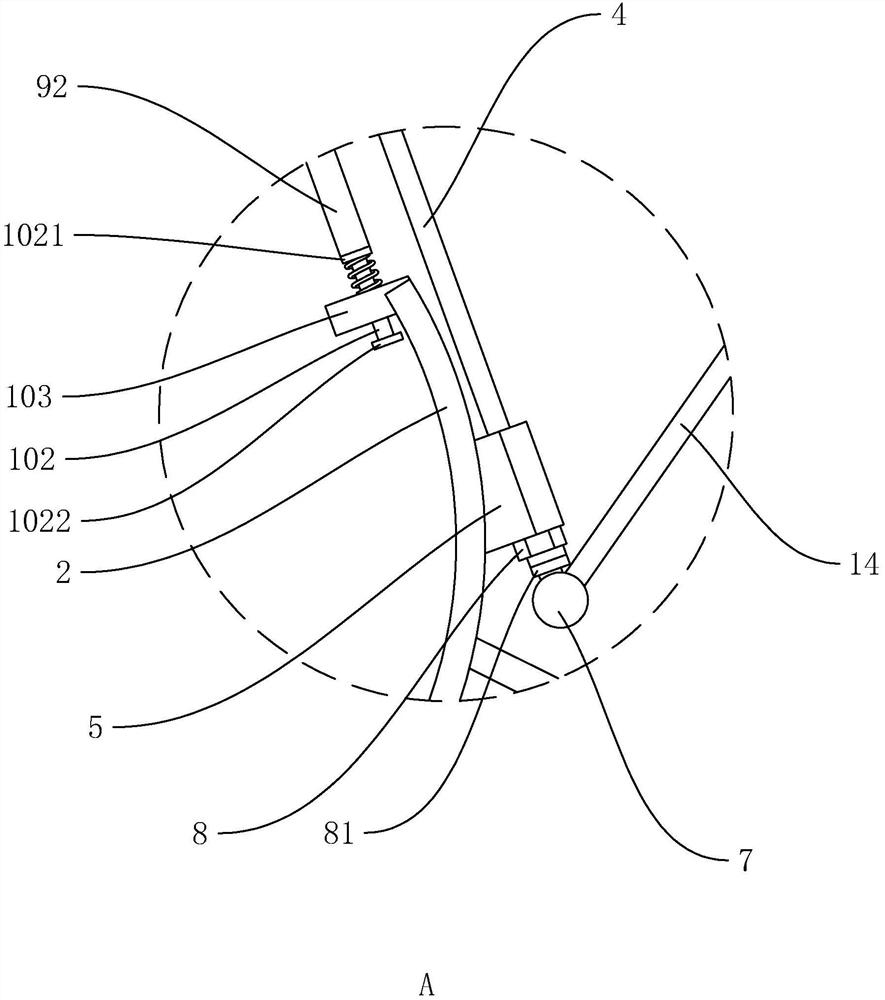

[0041] The following is attached Figure 1-4 The application is described in further detail.

[0042] The embodiment of the present application discloses a roadbed filling construction method. refer to figure 1 , the subgrade filling construction method comprises the following steps:

[0043] Step S1, base treatment: clean up the cultivated soil, weeds, shrubs, etc. on the original ground within the scope of subgrade filling, and pile up the cleared topsoil, and backfill, tamp and adjust the pits and holes on the original ground after cleaning. Flat, the ground should be compacted before filling;

[0044] Step S2: Filling and compacting: adopt layered filling according to the parallel lines of the road surface, and both sides of the subgrade are widened by 30-50 cm during filling;

[0045] Step S21: The dump truck unloads the soil according to the distance between the piles of soil calculated according to the vehicle capacity. The thickness of the subgrade fill layer is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com